Equipment and method of plasma arc and electric heat combination for cracking organic waste

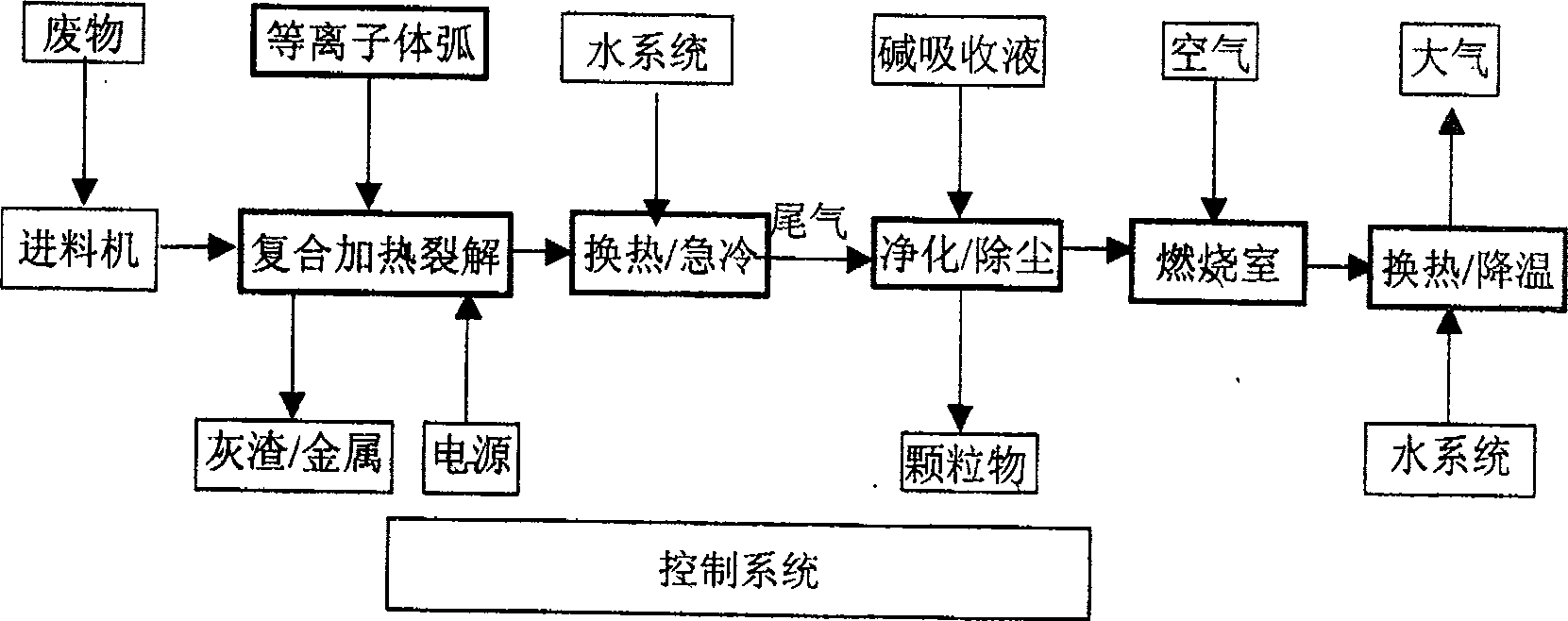

A combination of plasma and electrothermal technology, which is applied to solid waste removal, combustion methods, lighting and heating equipment, etc., can solve the problems of increasing the burden on the exhaust gas treatment system, uniformly distributing heat in large areas, and small high-temperature areas. Achieve simple and reliable equipment, improve overall efficiency, and control exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

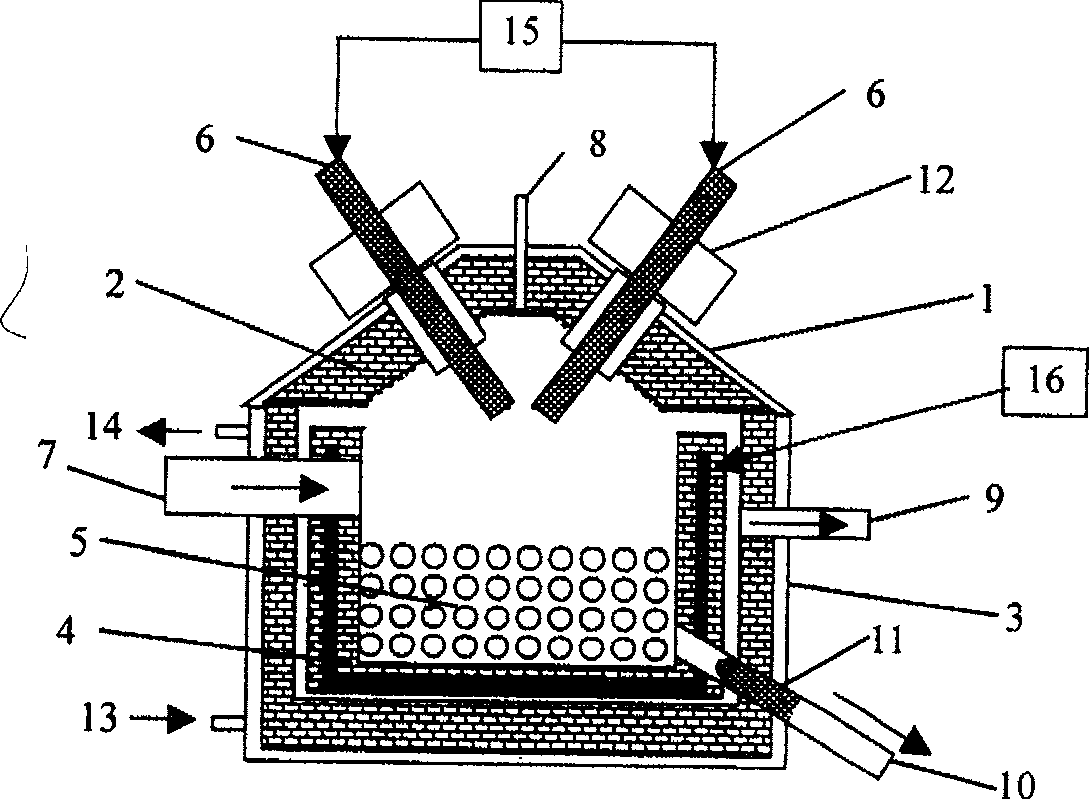

[0051] See attached figure 1 , making a plasma arc furnace, such as figure 1 structure shown. The upper furnace body 1 and the lower furnace body 3 are steel shells, and their inner sides are provided with refractory materials and heat insulating material linings 2, and the bottom of the lower furnace body 3 is provided with a crucible 4, and a partition is added between the crucible 4 and the inner wall of the furnace. heat screen.

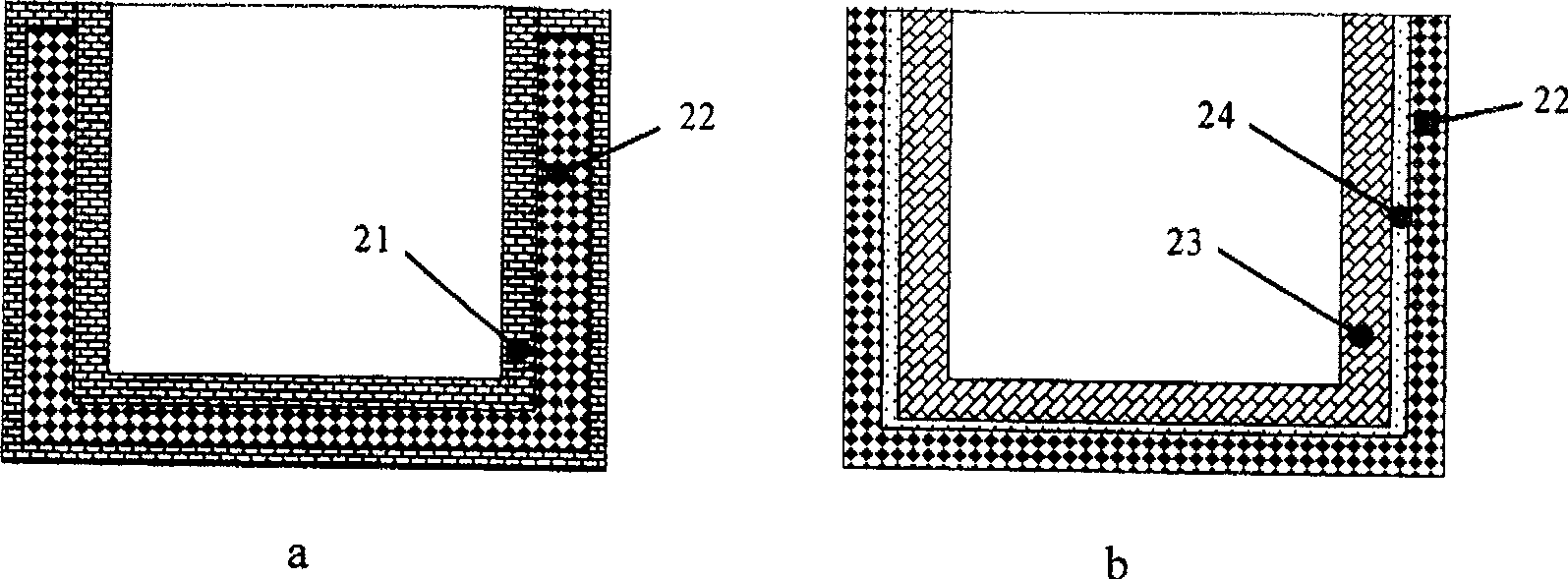

[0052] refer to figure 2 b is a wrapped structure, the innermost layer is a crucible 23 made of conductive refractory material, the crucible 23 is wrapped with a layer of insulating refractory material 24, and the insulating refractory material 24 is wrapped with a heating element 22.

[0053] in the attached figure 1 In a plasma arc furnace, use figure 2 The structure shown in b has a crucible wrapped by a heating element, combined with the cracking treatment of organic waste, the present invention is described in detail, and its technolo...

Embodiment 2

[0061] combined with figure 1 , 2 and 3, on the basis of embodiment 1, the device and method are further described.

[0062] The difference lies in the plasma arc part: 2 water-cooled copper electrodes, connected to a DC plasma power supply, the plasma power is 50kW, the electric heating is 100kW, and the processing capacity is 120-180 kg / hour. When the temperature of the crucible wall is controlled within the range of 1473-1573K , power consumption is 0.9-1.2kW-h / kg.

[0063] The structure in which the electric heating element is embedded in the crucible is adopted. The crucible is made of magnesium oxide material, and the combination with the electric heating element refers to figure 2 a. The structure is an embedded structure. The silicon carbon heating element 22 is wrapped on the inner layer of the crucible 21 made of non-conductive refractory material, and then an outer layer of the crucible made of non-conductive refractory material of matching size is placed outsi...

Embodiment 3

[0069] The processing object and the embedded structure of the heating element in this embodiment are the same as those in Embodiment 2, but the method for realizing the embedded structure is different.

[0070] The crucible 4 of this embodiment has an integral structure, and the material is alumina. The high-temperature electric heating wire is penetrated by punching holes on the top to form an embedded structure of heating elements. The temperature of the crucible wall is in the range of 1373-1473K. Silicon-molybdenum electric heating rods can also be used to embed the magnesia crucible blank in advance, process it into a suitable shape, and then sinter it to form a heating element embedded structure. The combination of silicon molybdenum electric heating rod and magnesium oxide can get a higher working temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com