Method for manufacturing diamond drum

A manufacturing method and diamond technology, which is applied in the manufacture of tools, metal processing, metal processing equipment, etc., can solve the problems of insufficient connection between the grinding block and the substrate, the limitation of the thickness of the grinding layer, and the high production cost, so as to increase the thickness and production cost. The effect of reducing and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention will be further described:

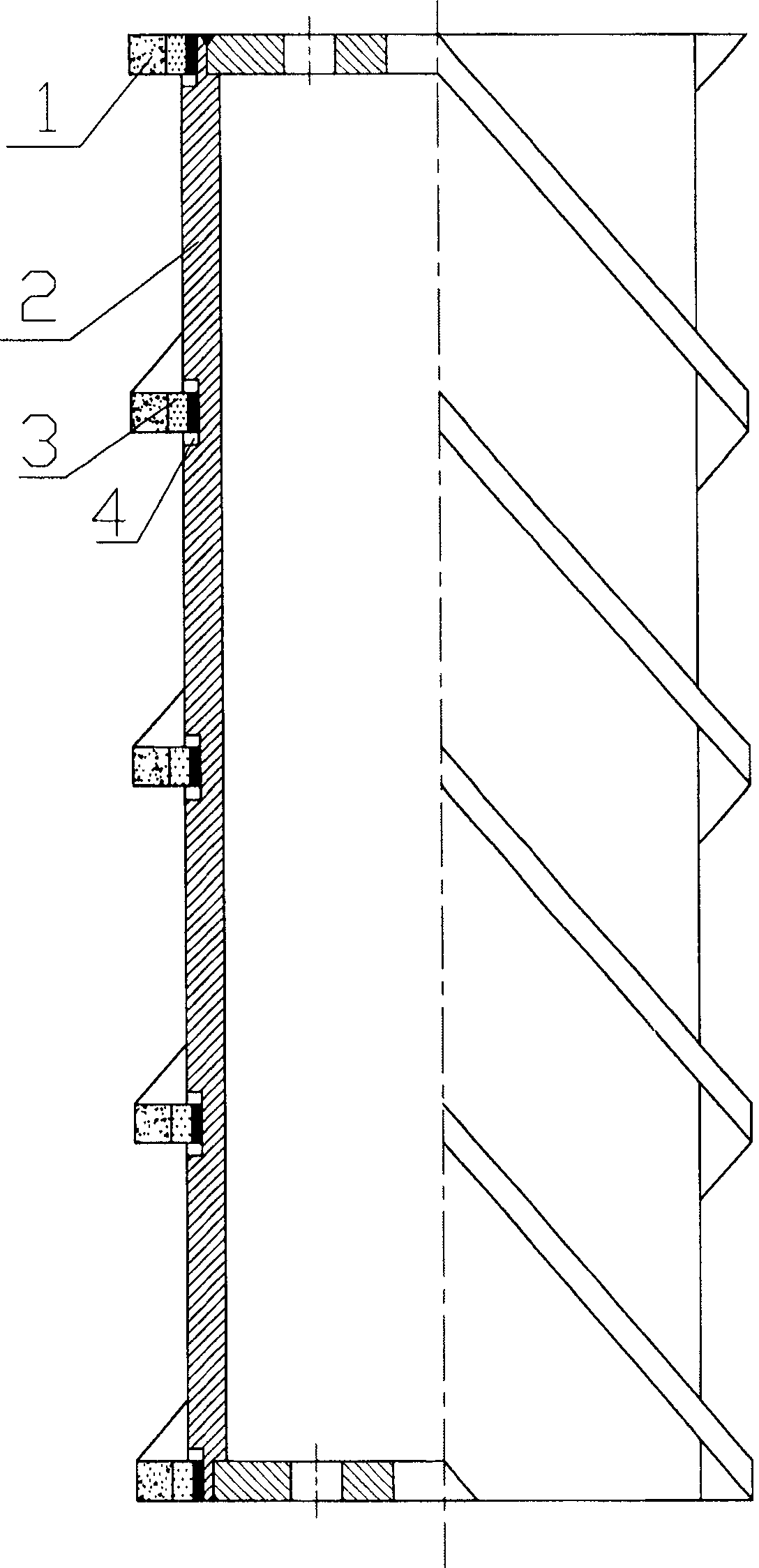

[0012] figure 1 Structural schematic diagram of the diamond roller made by adopting the manufacturing method of the prior art;

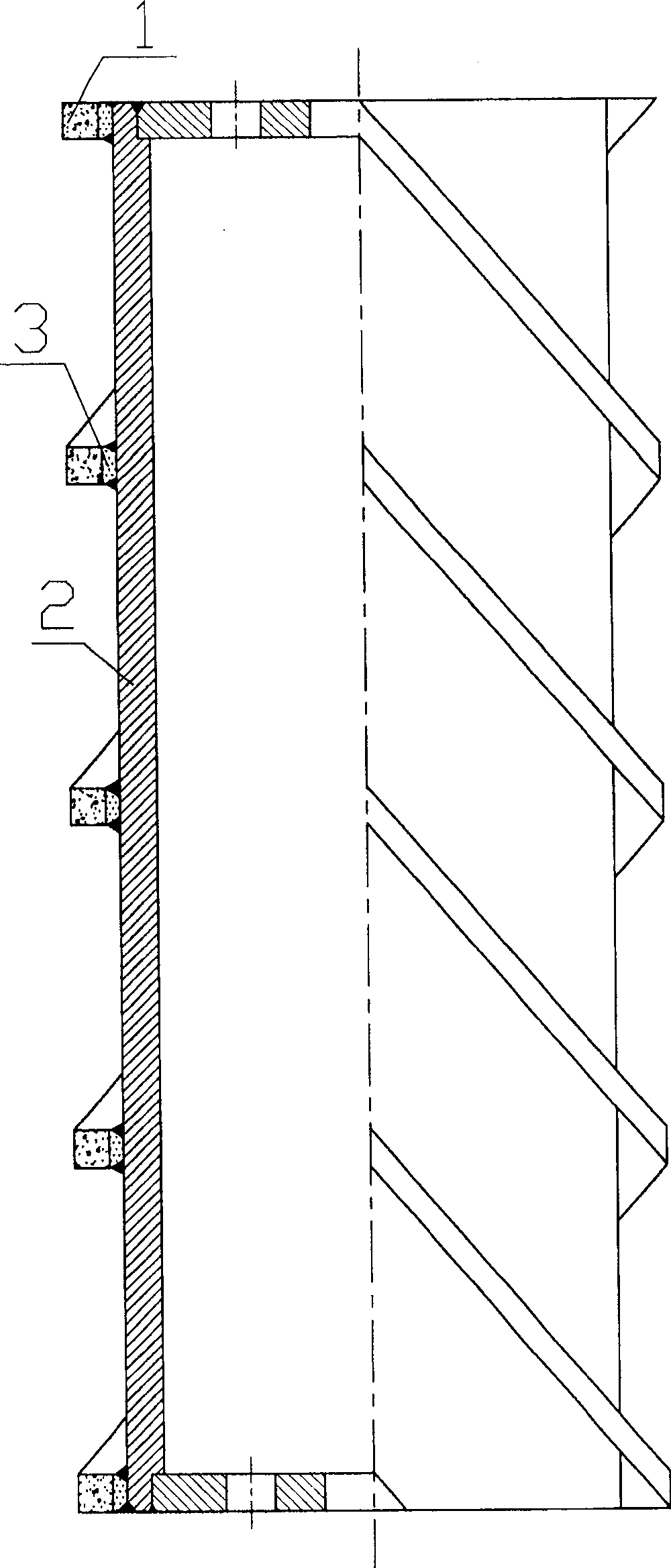

[0013] figure 2 It is a structural schematic diagram of a diamond roller without grooves made by the method of the present invention;

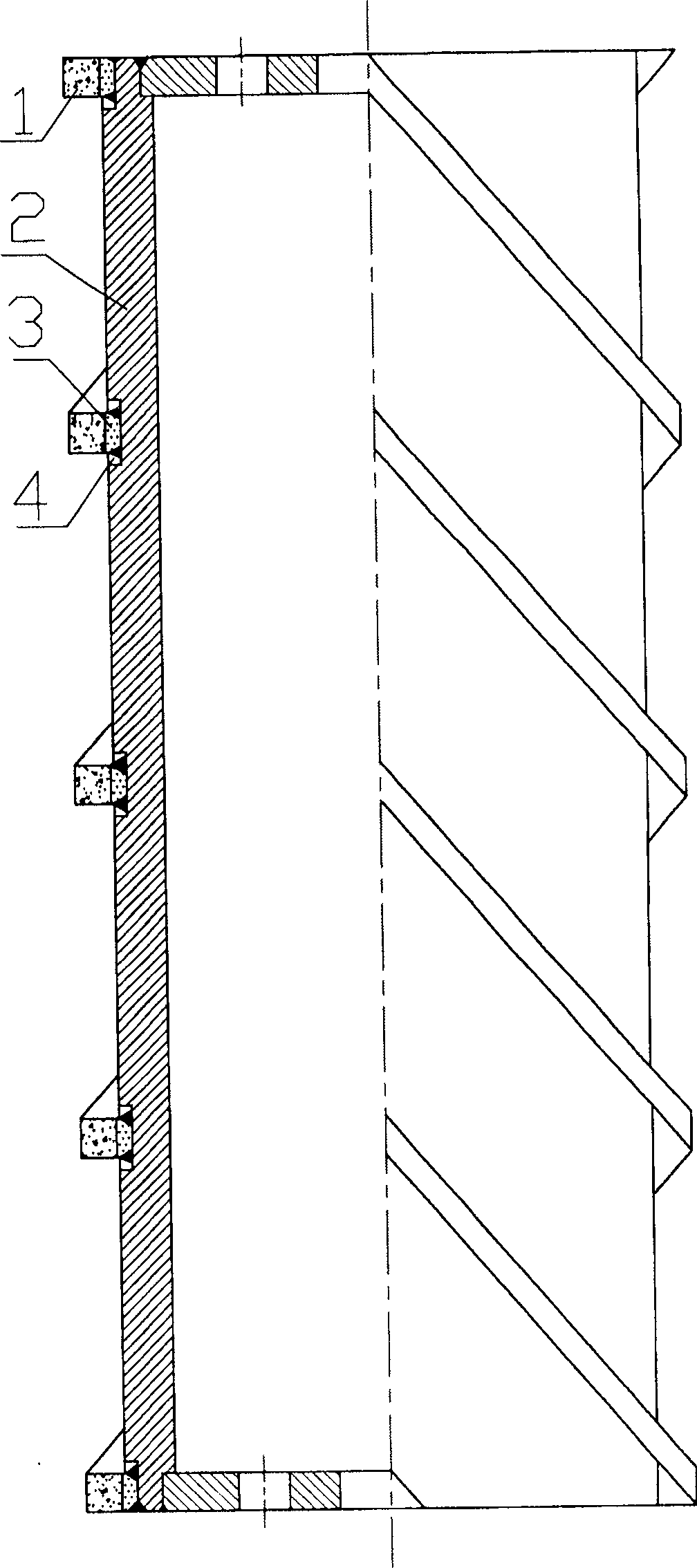

[0014] image 3 It is a structural schematic diagram of a grooved diamond roller manufactured by the method of the present invention.

[0015] figure 1 As shown, first press and sinter the diamond grinding block 1 to make it into the designed shape, draw a line according to the designed curve on the substrate 2, place the diamond grinding block 1 along the drawn line and weld it by fusion welding, in order to make the welding It is stronger, and the transition layer 3 of the grinding block is preferably thicker than when brazing is used. The transition layer powder can be non-self-fluxing alloy powder. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com