Delicate flavor of oyster and its production method

A technology for flavoring agents and oysters, applied in the field of food additive flavoring, can solve the problems of inability to taste the natural seafood and plant umami, no natural green natural flavor, and adverse effects on physical and mental health, achieve macro balance and promote physiological functions, and has a unique formula. , the effect of high application and food value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

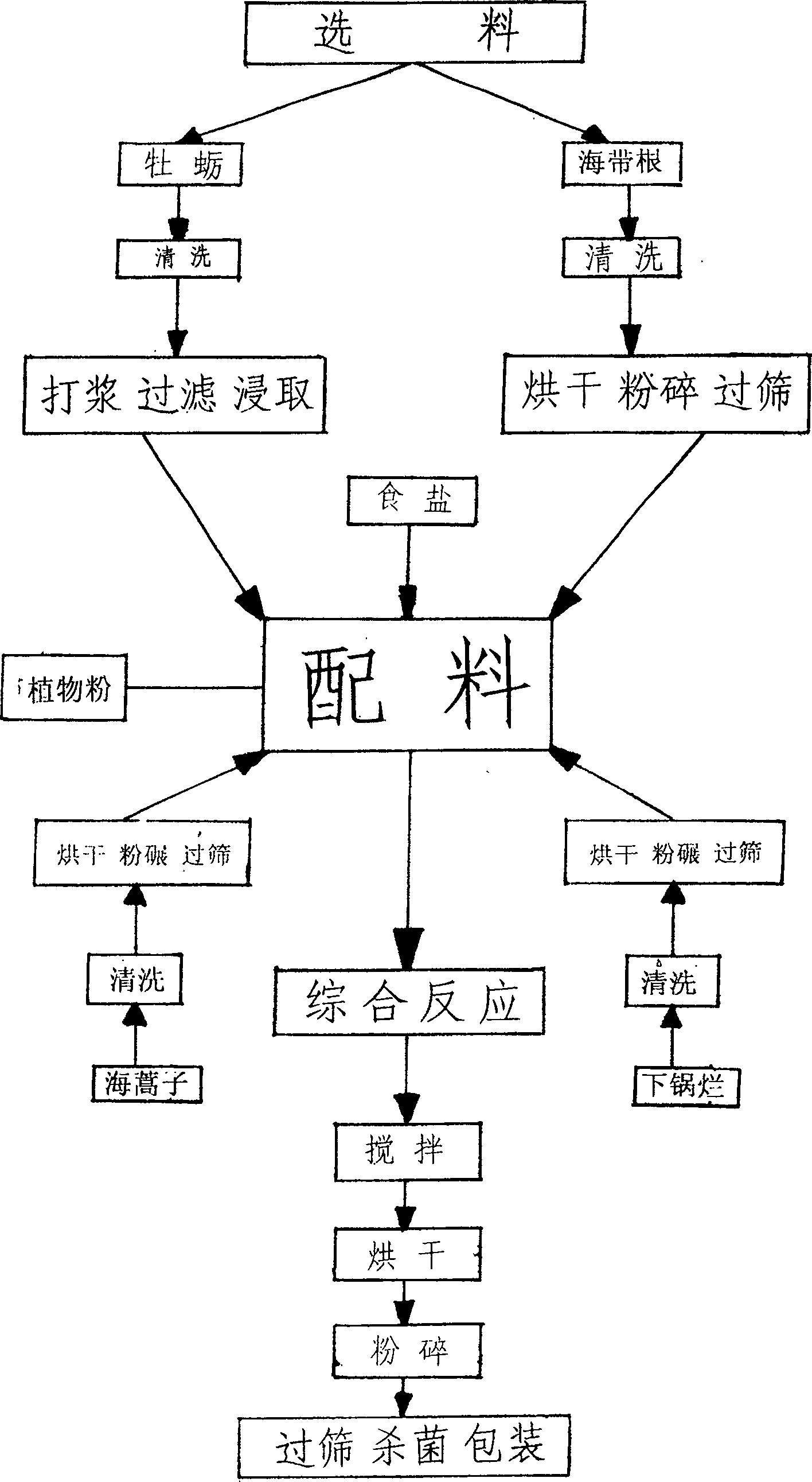

Image

Examples

Embodiment 1

[0020] (1) Cleaning and beating the selected fresh oyster meat, filtering with a 70-mesh sieve, and leaching to obtain oyster meat pulp;

[0021] (2) Cleaning, shredding, drying, pulverizing and grinding the sea wormwood, and passing through a 70-mesh sieve to obtain sea wormwood powder;

[0022] (3) Washing, chopping, drying, pulverizing and grinding the cooked rotten powder, and passing through a 75-mesh sieve to obtain the cooked rotten powder;

[0023] (4) cleaning, shredding, drying, pulverizing and grinding the kelp root, passing through a 75-mesh sieve to obtain the kelp root powder;

[0024] (5) Quantitatively prepare the required raw materials in proportion, namely: 67.5kg of oyster pulp, 5.3kg of sea wormwood powder, 3.2kg of boiled rotten powder, 6kg of kelp root powder, 18kg of starch and 100g of salt to make oyster seasoning mixture. ;

[0025] (6) Heat the oyster seasoning mixture prepared in (5) for 1 hour and 20 minutes, and when the temperature is at 95° C.,...

Embodiment 2

[0029] (1) Cleaning and beating fresh oyster meat, filtering with an 80-mesh sieve, and leaching to obtain oyster meat pulp;

[0030] (2) Wash the sea wormwood, boiled rotten powder, and kelp root respectively, chop finely, dry, pulverize, and pass through an 80-mesh sieve to obtain sea wormwood powder, boiled rotten powder and kelp root powder:

[0031] (3) Ingredients: 675kg of oyster meat paste, 53kg of sea wormwood powder, 32kg of boiled rotten powder, 60kg of kelp root powder, 180kg of starch and 1000g of salt, stirred to make a semi-finished oyster seasoning mixture;

[0032] (4) heating the oyster flavoring semi-finished mixture prepared in (3) for 1 hour and 30 minutes at a temperature of 100° C., and stirring evenly to obtain the oyster flavoring liquid mixture;

[0033] (5) drying, pulverizing, and passing through an 80-mesh sieve with the prepared oyster flavoring liquid mixture in step (4) to make oyster flavoring powder;

[0034] (6) The oyster seasoning powder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com