Selective nickel series hydrogenating catalyst and its preparing process and uses

A hydrogenation catalyst and catalyst technology, applied in refining to remove heteroatoms, etc., can solve the problems of catalysts bearing hydrogenation load and poor hydrogenation stability, and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

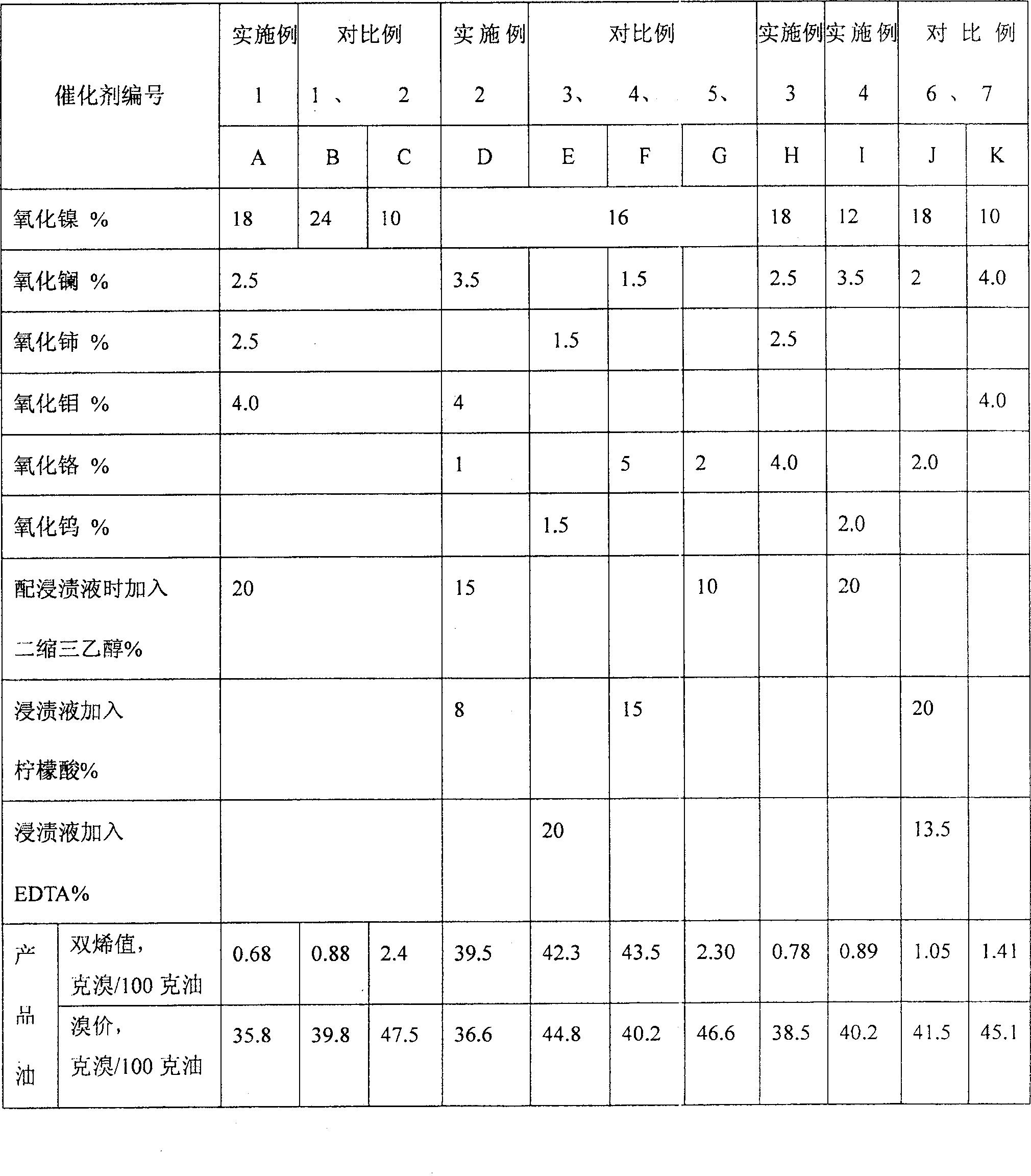

Examples

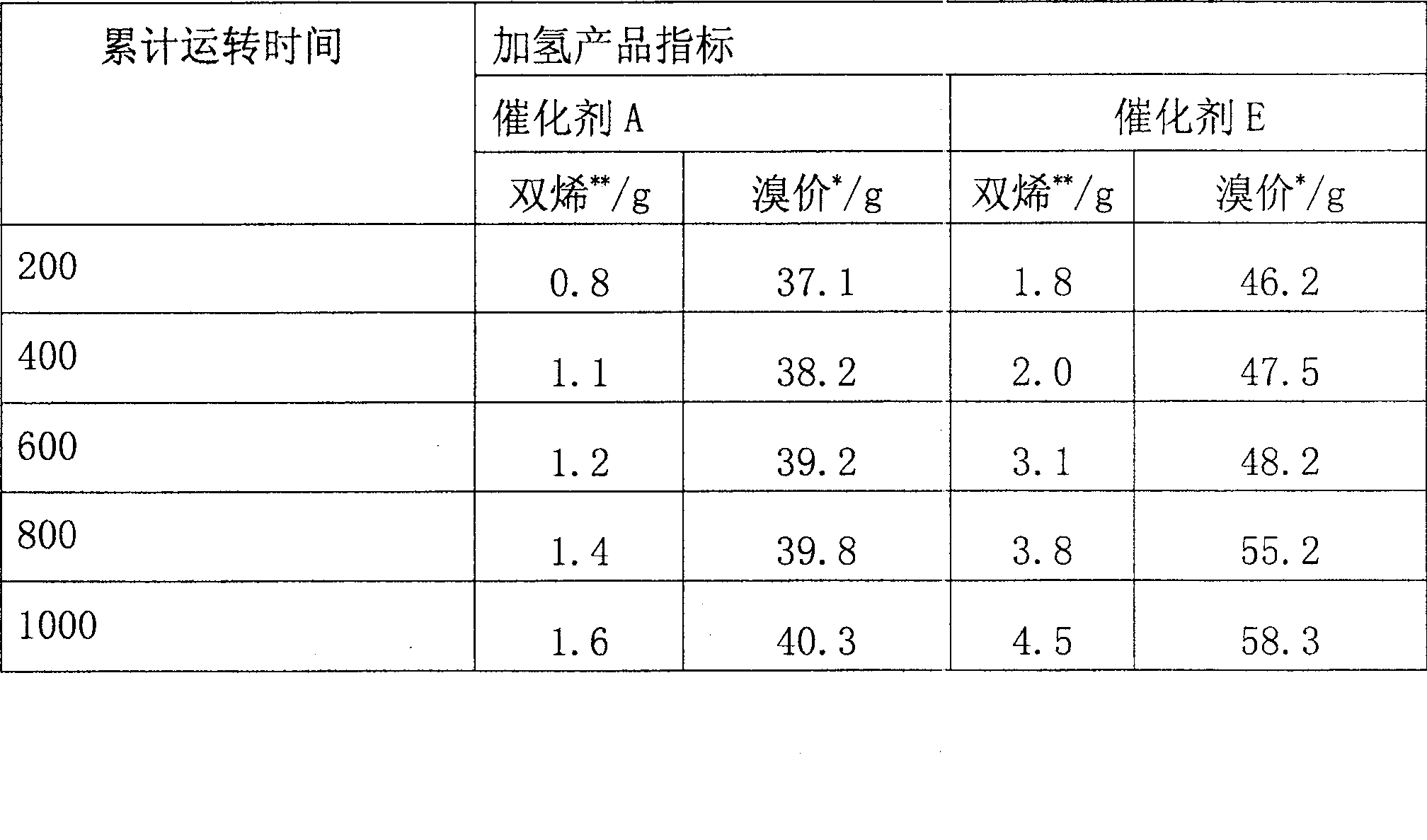

Embodiment 1

[0026] Add 300g of alumina powder to 140ml of water, knead and extrude into a strip, dry at 120°C in air, and bake at 860°C for 4 hours to obtain Al 2 o 3 carrier.

[0027] Add 8.6g of nickel nitrate to 5ml of water and stir to dissolve, then add 1.4ml of triethanol, add 0.8g of cerium nitrate, 0.8g of lanthanum nitrate, 0.6g of ammonium molybdate, add 0.8g of citric acid, and adjust the pH value to 4. Impregnated on 10g carrier, aged for 12 hours, dried at 120°C, and calcined at 400°C for 4 hours to prepare catalyst A. Catalyst specific surface 160m 2 / g, pore volume 0.48ml / g.

Embodiment 2

[0031] Add 300g of alumina powder prepared by the nitric acid method to 140ml of water, knead and extrude into a strip, dry at 120°C in air, and roast at 900°C for 6 hours to obtain Al 2 o 3 carrier.

[0032] Add 7.7g of nickel nitrate to 5ml of water and stir to dissolve, then add 1.0ml of triethanol, add 1.1g of lanthanum nitrate, 0.8g of ammonium molybdate, add 0.5g of citric acid, adjust the pH value to 4, impregnate in 10g on the carrier, aged for 12 hours, dried at 120°C, and calcined at 450°C for 4 hours to obtain catalyst D. Catalyst specific surface area 148m 2 / g, pore volume 0.45ml / g.

Embodiment 3

[0036] Add 300g of alumina powder to 140ml of water, knead and extrude into a strip, dry at 120°C in the air, and roast at 980°C for 4 hours to obtain Al 2 o 3 carrier.

[0037] Add 8.6g of nickel nitrate to 5ml of water and stir to dissolve, add 0.8g of cerium nitrate, 0.8g of lanthanum nitrate, and 0.9g of chromium molybdate during stirring, adjust the pH value to 4, impregnate on 10g of carrier, and age for 12 hours at 120°C Drying and calcining at 400°C for 4 hours to obtain catalyst H. Catalyst specific surface area 136m 2 / g, the pore volume is 0.43ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com