Gluten free edible seed powder and its production method

A manufacturing method, gluten-free technology, applied in plant protein processing, etc., can solve the problems of increasing production steps, nutrient loss of gramineous edible seed powder, and failure to meet product cost requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

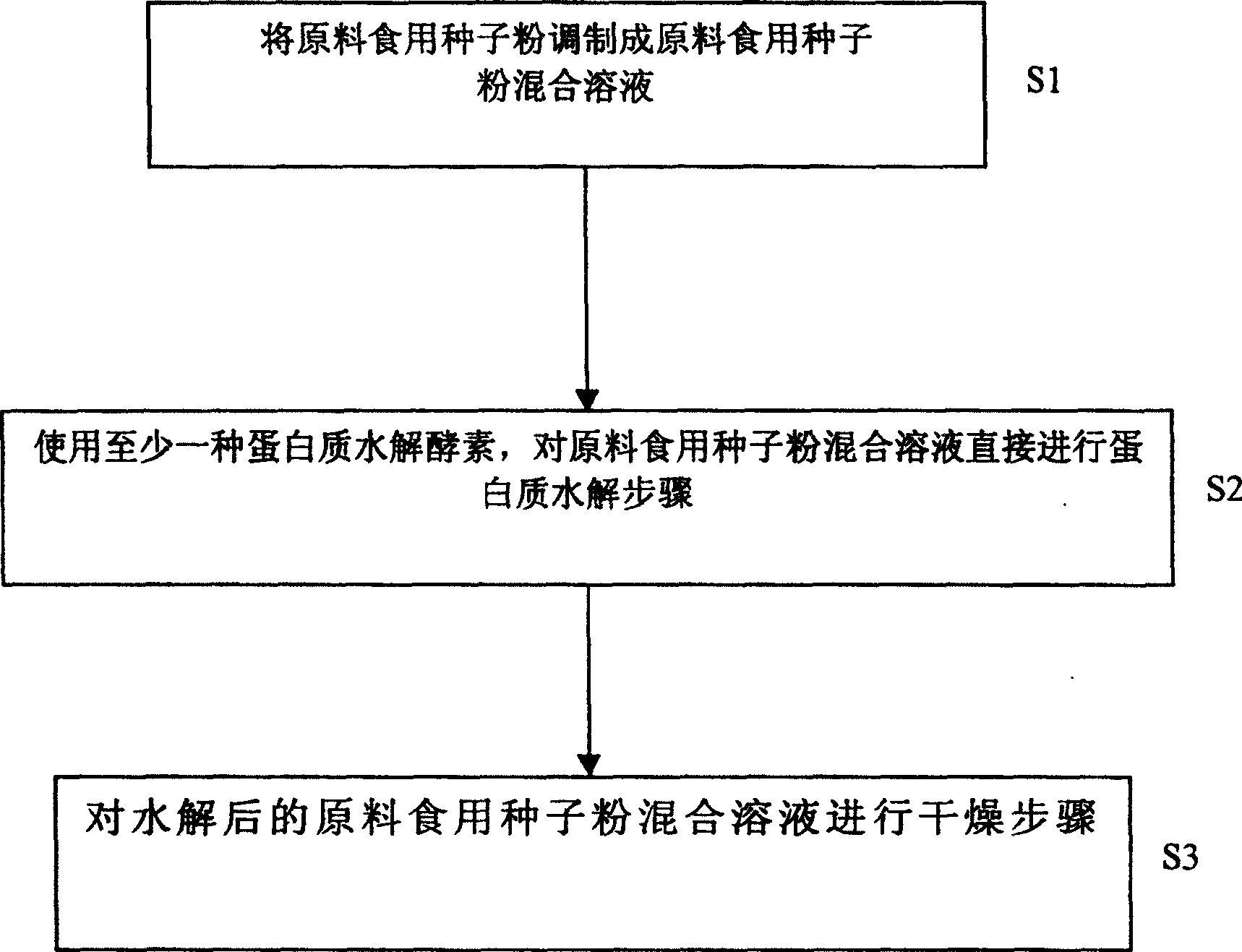

Method used

Image

Examples

Embodiment 1

[0027] Embodiment one : Gluten-free wheat flour

[0028] The gluten-free wheat flour is processed by the following steps: mixing wheat flour and water to prepare a mixed solution, wherein the easy-to-mix solid content is about 20% to 30% by weight. Add the proteolytic enzyme obtained by fermentation and isolation of cactus bacillus (Bacillus) provided by Novozymes, wherein the ratio of protease (enzyme activity 2.4 activity units / gram (AU / g)) to cereal protein is about 0.4 by weight; hydrolysis temperature At about 50°C, the initial pH value is about pH 6.3. Under these conditions, it acts for 3 hours. After the action, the pH value dropped slightly to about pH 5.8, and the temperature was increased to 90°C and maintained for 20 minutes. It is then dried with a tumble dryer. The dried solids were then crushed.

[0029] According to the gluten-free food standard Codex Stan 118-1981 formulated by the Codex Aliment Commission (CAC) composed of the Food and Agriculture Organ...

Embodiment 2

[0030] Embodiment two : Gluten Free Mixed Grass Edible Seed Powder

[0031] Gluten-free mixed gramineous edible seed powder is processed by the following steps: mixing wheat, oats, rice flour with water, vegetable oil, lecithin, minerals and vitamins to prepare a mixed solution, the solid content of which is easy to mix About 35% by weight. Add the proteolytic enzyme obtained by the fermentation and isolation of cactus bacillus (Bacillus) provided by Novozymes, wherein the ratio of protease (enzyme activity 2.4 activity units / gram (AU / g)) to cereal protein is about 4 by weight; the hydrolysis temperature is about The temperature is 50°C, and the pH value is maintained at about pH 6.3. After acting under these conditions for 1 hour, the temperature was increased to 90° C. and maintained for 20 minutes. Then dry it with a tumble dryer. Then the dried solids were crushed.

[0032] According to the gluten-free food standard Codex Stan 118-1981 formulated by the Codex Aliment C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com