Series resonant high-frequency chain sinusoidal wave inverse power supply circuit

A technology of series resonance and inverter power supply, which is applied in the direction of high-efficiency power electronic conversion, irreversible DC power input conversion to AC power output, electrical components, etc., which can solve the problem of increasing the difficulty of transformer design, the complexity of circuit work, and inverters. Problems such as low transmission efficiency and complex circuit structure achieve the effect of reducing the number of winding turns, simple control logic, and simplified circuit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

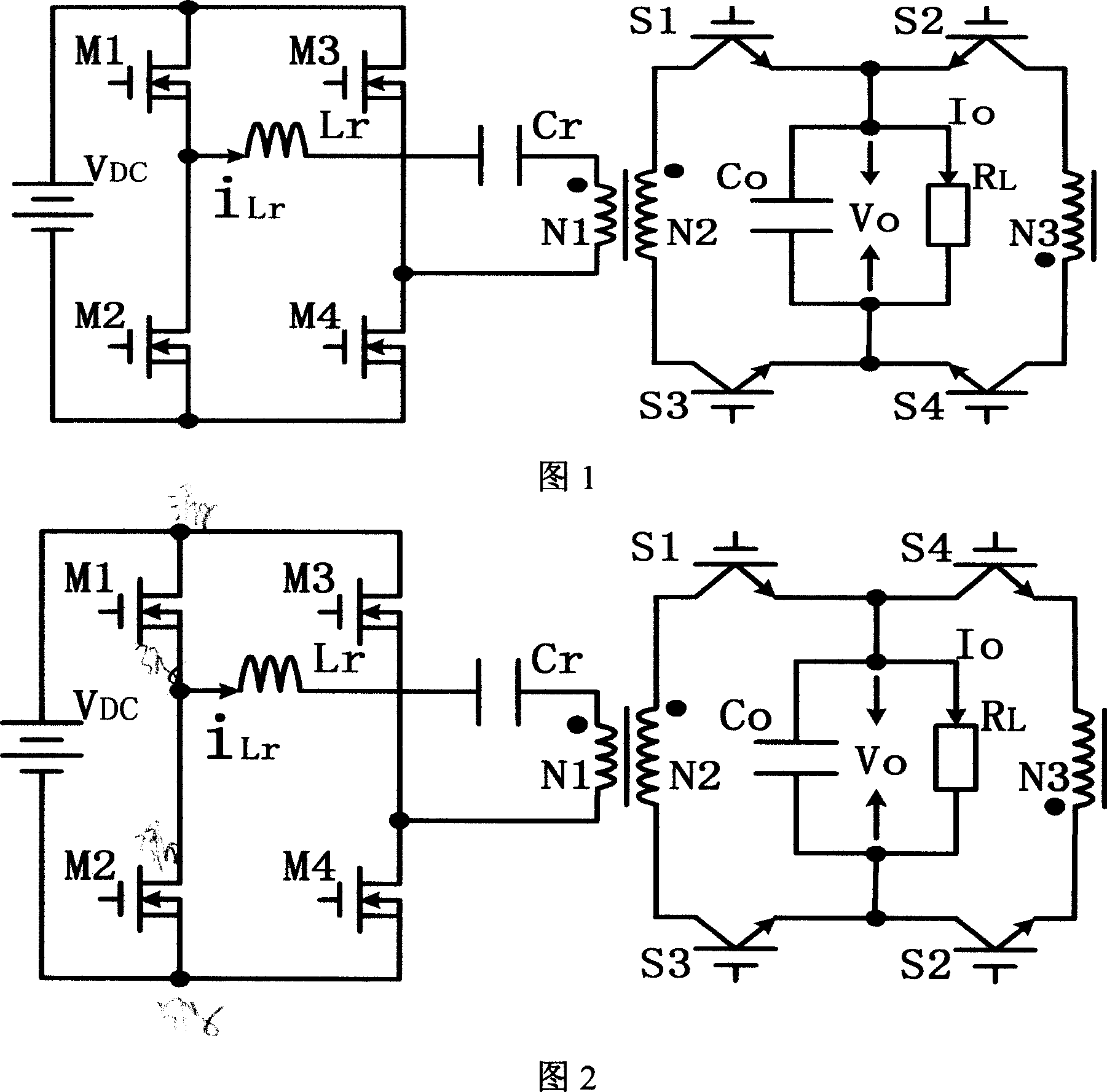

Embodiment 1

[0020] In Fig. 1, the front-end full-bridge inverter circuit adopts a full-bridge structure composed of the first to fourth front-stage power tubes, and the DC input power V DC The anode of the positive pole is connected to the drains of the first pre-stage power tube M1 and the third pre-stage power tube M3, and the negative pole is connected to the source of the second pre-stage power tube M2 and the fourth pre-stage power tube M4; the series resonant inductance L r One end is connected to the source of the first pre-stage power tube M1 and the drain of the second pre-stage power tube M2, and the other end is connected to the series resonant capacitor C r One end of the high frequency transformer is connected; the same name end of the primary winding N1 of the high frequency transformer is connected with the series resonant capacitor C r The other end is connected, and the opposite end is connected to the source of the third pre-stage power tube M3 and the drain of the fourt...

Embodiment 2

[0025] In Fig. 2, the front full bridge inverter circuit adopts a full bridge structure composed of the first to fourth front power tubes, and the DC input power V DC The anode of the positive pole is connected to the drains of the first pre-stage power tube M1 and the third pre-stage power tube M3, and the negative pole is connected to the source of the second pre-stage power tube M2 and the fourth pre-stage power tube M4; the series resonant inductance L r One end is connected to the source of the first pre-stage power tube M1 and the drain of the second pre-stage power tube M2, and the other end is connected to the series resonant capacitor C r One end of the high frequency transformer is connected; the same name end of the primary winding N1 of the high frequency transformer is connected with the series resonant capacitor C r The other end is connected, and the opposite end is connected to the source of the third pre-stage power tube M3 and the drain of the fourth pre-stag...

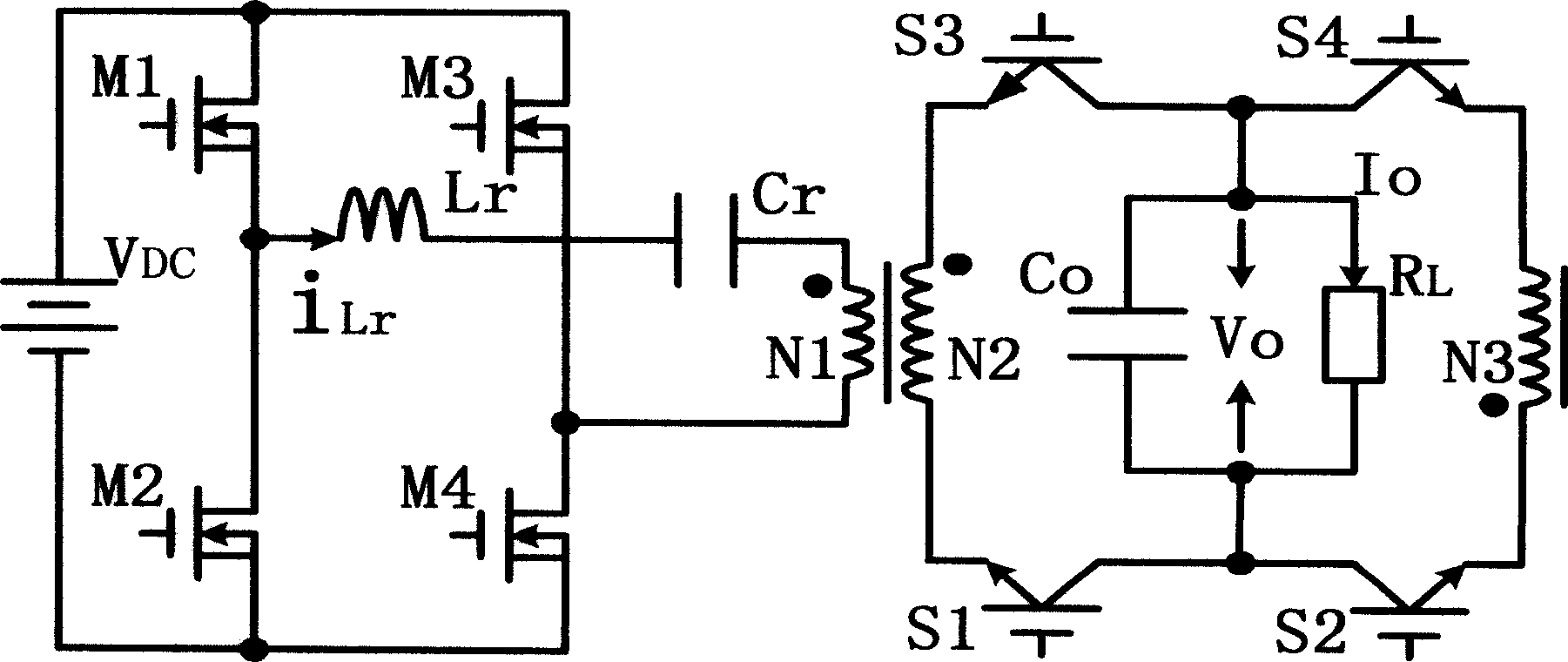

Embodiment 3

[0030] exist image 3 Among them, the front-stage full-bridge inverter circuit adopts a full-bridge structure composed of the first to fourth front-stage power tubes, and the DC input power V DC The anode of the positive pole is connected to the drains of the first pre-stage power tube M1 and the third pre-stage power tube M3, and the negative pole is connected to the source of the second pre-stage power tube M2 and the fourth pre-stage power tube M4; the series resonant inductance L r One end is connected to the source of the first pre-stage power tube M1 and the drain of the second pre-stage power tube M2, and the other end is connected to the series resonant capacitor C r One end of the high frequency transformer is connected; the same name end of the primary winding N1 of the high frequency transformer is connected with the series resonant capacitor C r The other end is connected, and the opposite end is connected to the source of the third pre-stage power tube M3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com