Armature coil down-lead head width-limited flat mould

A technology of armature coil and lead head, which is applied in the field of motor production equipment, can solve the problem that the width of the lead head cannot meet the design requirements at one time, and achieve the effects of shortening the production cycle, improving product quality, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

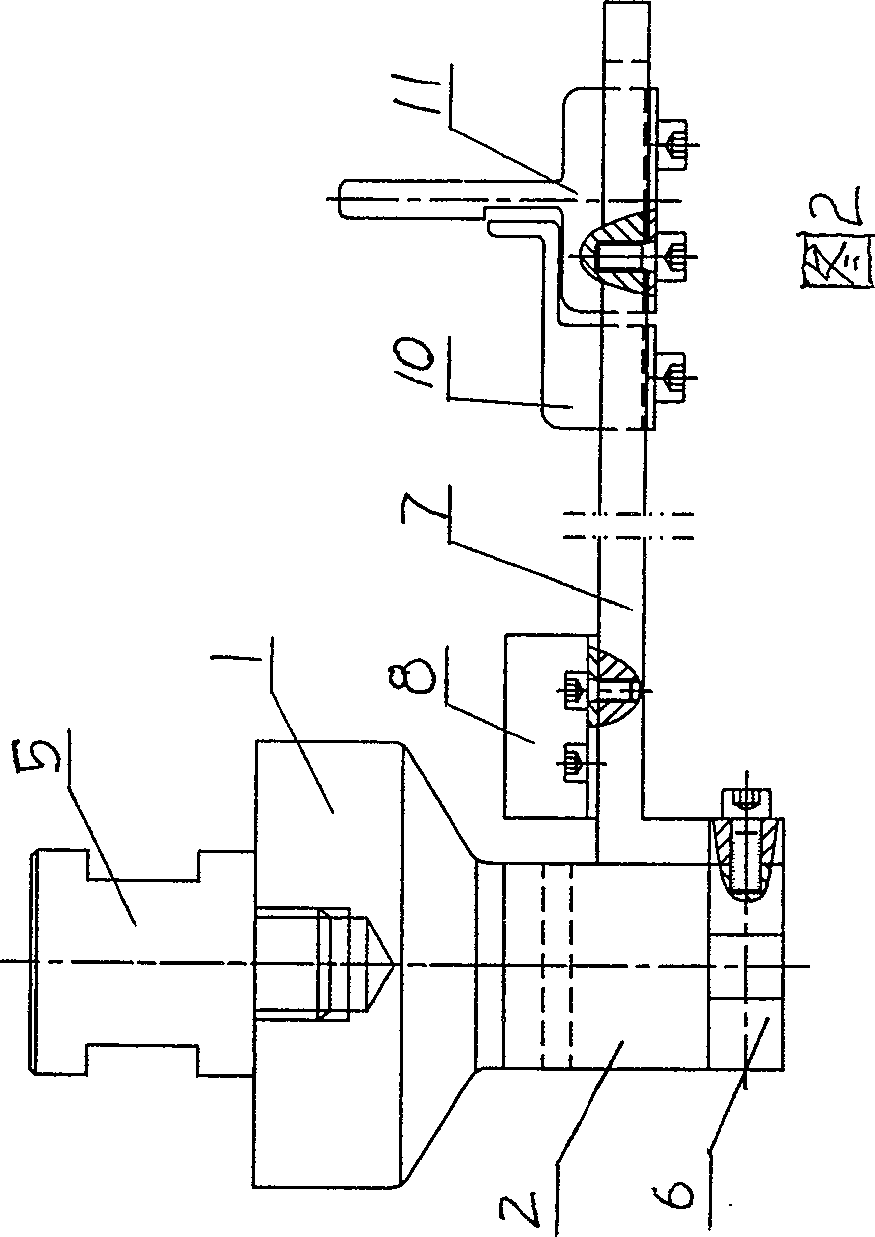

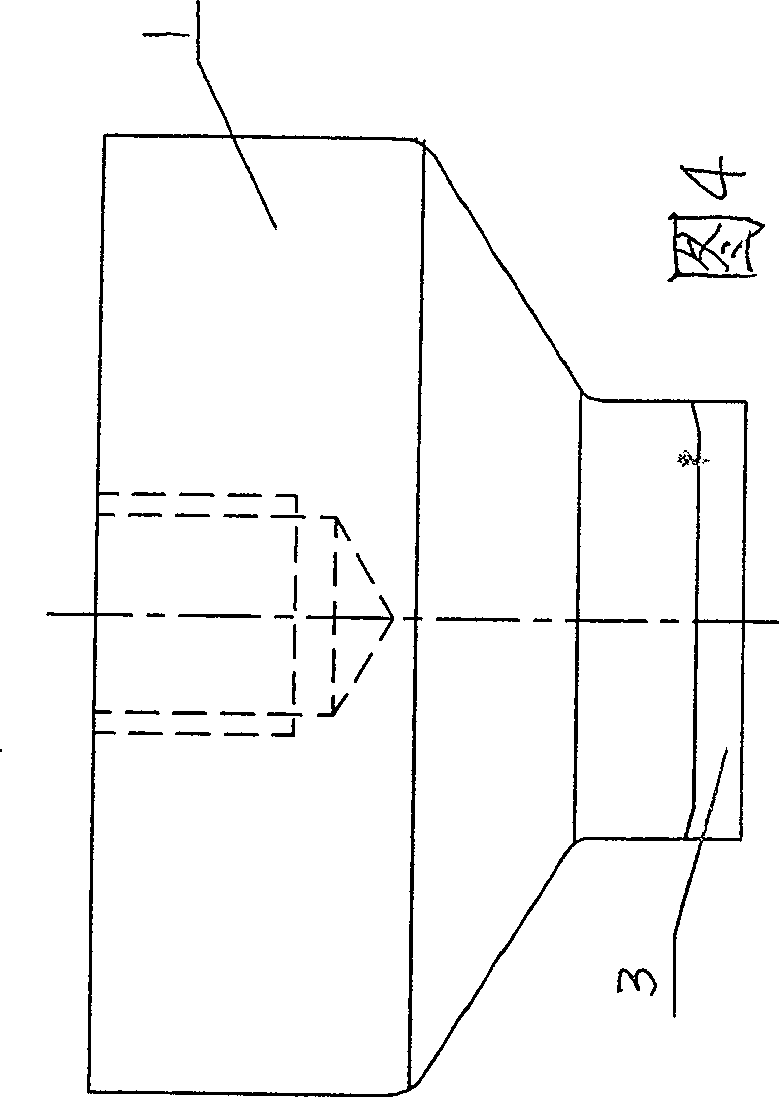

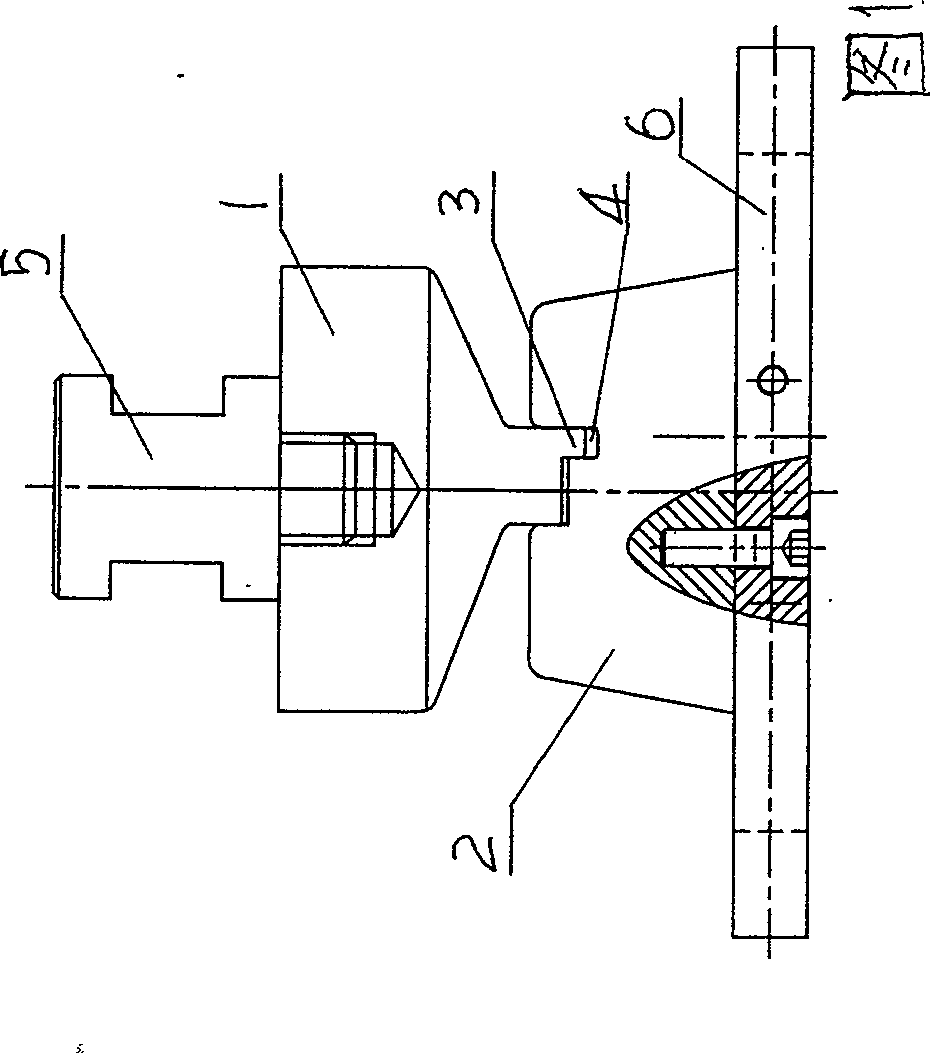

[0028] The armature coil lead head is limited in width and flattened. It includes an upper die 1 and a lower die 2. A rib 3 is provided on the stamping end face of the upper die 1, and a rib 3 is formed on the stamping end face of the lower die 2 to match the stamping end face of the upper die. The protruding rib 3 fits with the groove 4 whose width is equal to the designed width of the armature coil lead head. In order to better realize the connection and fixation of the upper mold, the lower mold and the punching machine, a screw hole is opened on the top of the upper mold 1, and the upper mold handle 5 is fixed in the screw hole, and the upper mold and the punching machine can be connected through the upper mold handle 5. Fixed; screw holes are provided at the bottom of the lower die 2, and a base plate 6 is fixed at the bottom of the lower die. The two ends of the base plate 6 are provided with grooves for fixing with the punch press. The lower die is placed on the punch pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com