Biological enzyme hydrolysis process for oyster to prepare nutritious liquid and nutritious powder

A nutrient solution and bio-enzyme technology, applied in the deep processing of oysters, the field of bio-enzymatic hydrolysis of oysters to prepare nutrient solution and nutrient powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

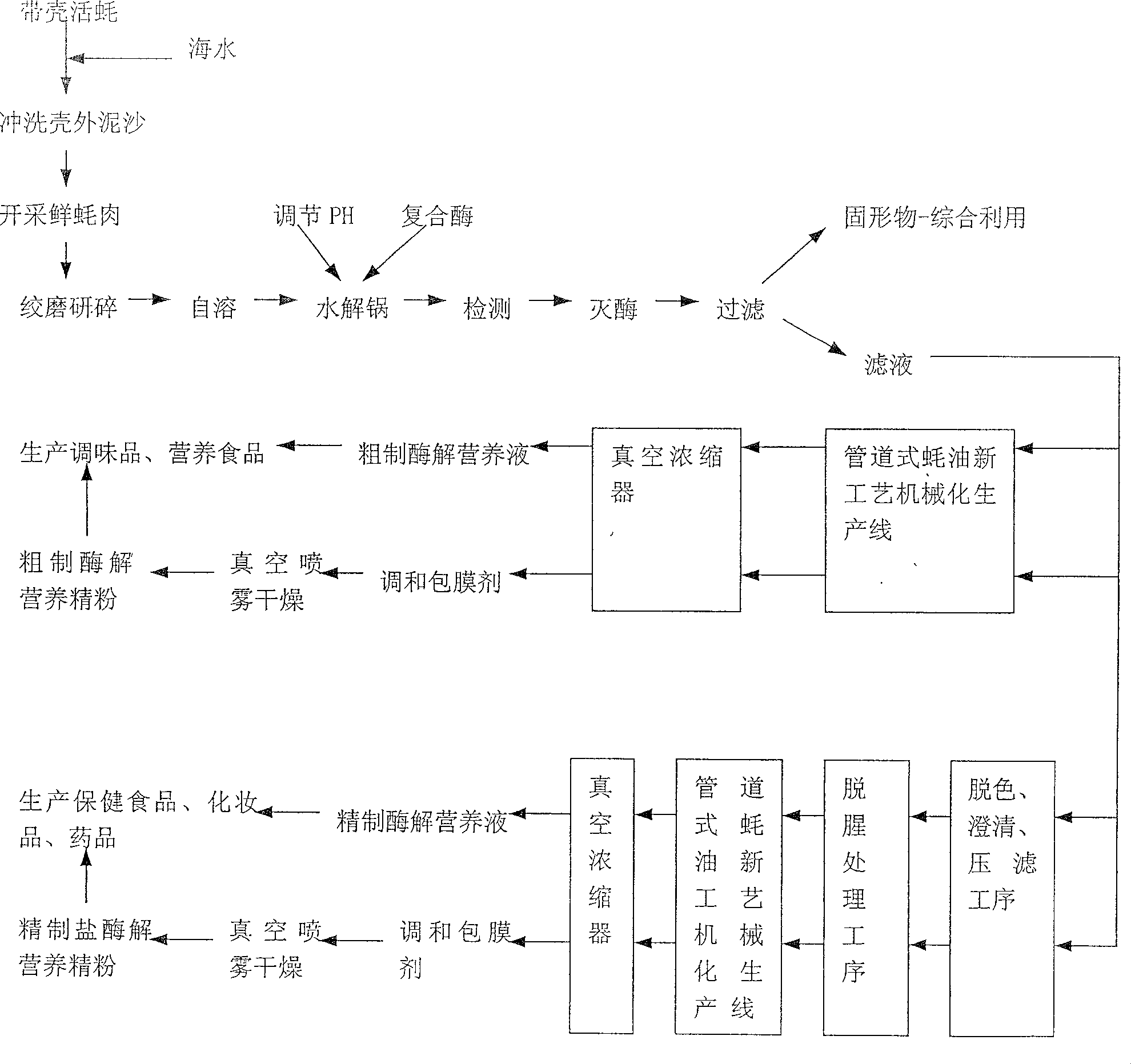

[0018] Such as figure 1 As shown, the shelled live oysters collected from the sea are washed with sea water to clean the sediment outside the shells, the shells are removed, and the live oyster meat is taken out. Grind the fresh oyster meat, and use the enzymes in the cells of the oyster body to autolyse the tissue at a room temperature not higher than 25°C. The autolysis time should not exceed 24 hours. The autolysis process contributes to the effect of the enzymatic hydrolysis process in the next step. During enzymatic hydrolysis, a single enzyme or a compound enzyme can be added, but the effect of using a compound enzyme is better than that of a single enzyme. In this embodiment, a compound enzyme is selected to be added, and the amount of the enzyme added is 30-60 mg per kilogram, and the enzymolysis is carried out at a temperature of 40-50° C. for 1.5-3.5 hours. The compound enzyme selected can be acidic, alkaline or neutral. When selecting an acid compound enzyme such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com