Water flowmeter shell manufacture method

A manufacturing method and technology for a water meter case, which are applied in the fields of water meter parts and water meter cases, can solve the problems of pollution of the working environment, labor intensity of workers' processing, cumbersome processes, etc., and achieve less pollution of the working environment, considerable economic benefits, and simple processing technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

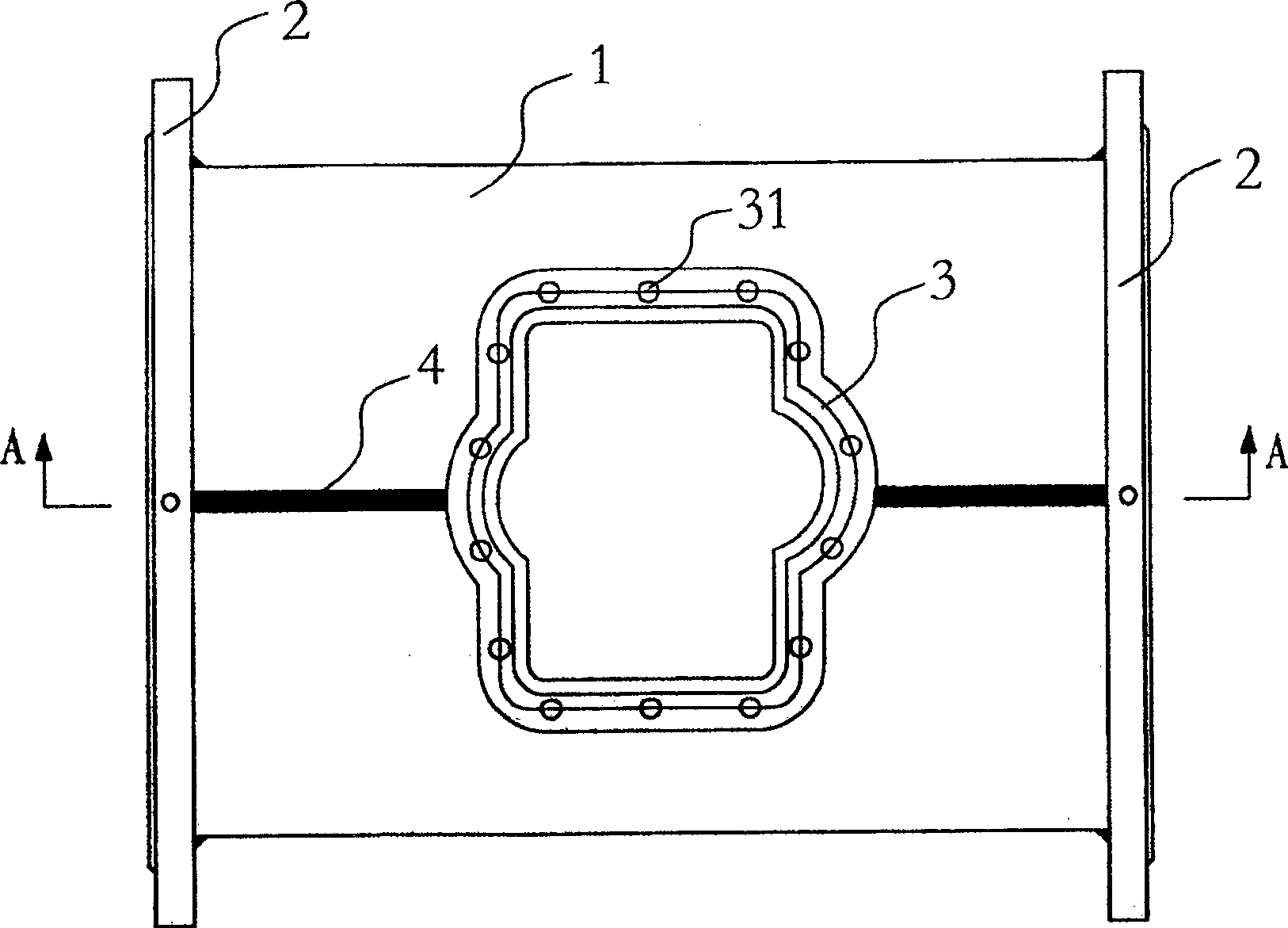

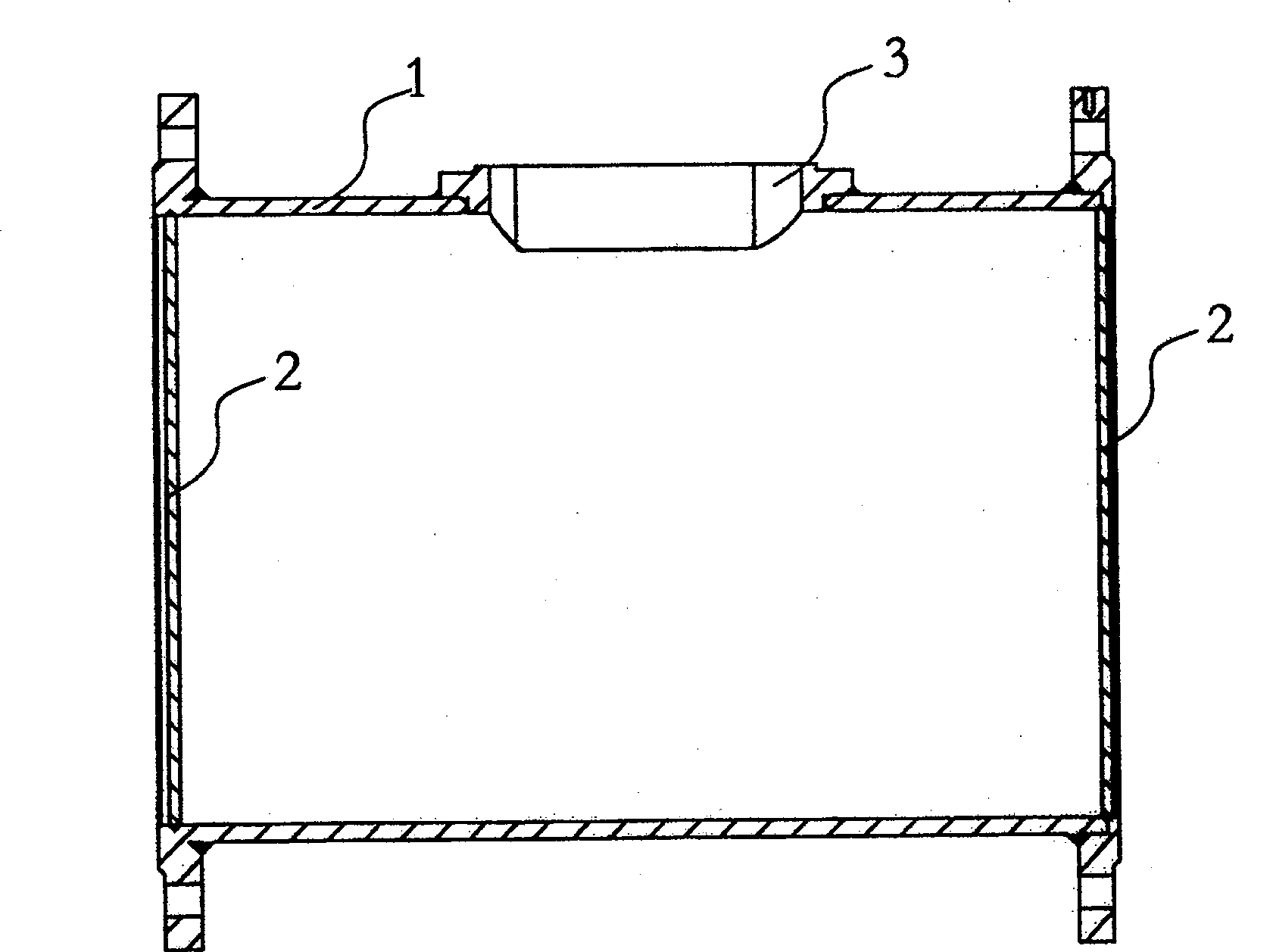

[0020] refer to figure 1 and figure 2 In this embodiment, a water meter casing includes a casing 1, a head flange 3 and a port flange 2. The casing 1 is a cylindrical body formed by cutting A3 steel plates and then winding and welding. The cylindrical body The diameter is more than 400mm, the surface of the shell 1 forms a welding line 4, the head flange 3 is fixed in the middle of the welding line 4 of the shell 1 by welding, the port flange 2 is fixed on the port of the shell 1 by welding, and the port flange 2. Standard flanges or casting flanges can be used. The shape of the head flange 3 is a rectangle with symmetrical arcs on both sides, and several mounting holes 31 are provided on its peripheral surface. The head flange 3 can be cast machined flanges,

[0021] Its steps of the manufacturing method of aforementioned water watch case...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com