Focal-distance and view-field-adjusting liquid microlens and its production

A manufacturing method and micro-lens technology, which is applied in the direction of lenses, optics, instruments, etc., can solve the problem that the field of view and the lens cannot be adjusted at the same time, and achieve the effect of precise focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

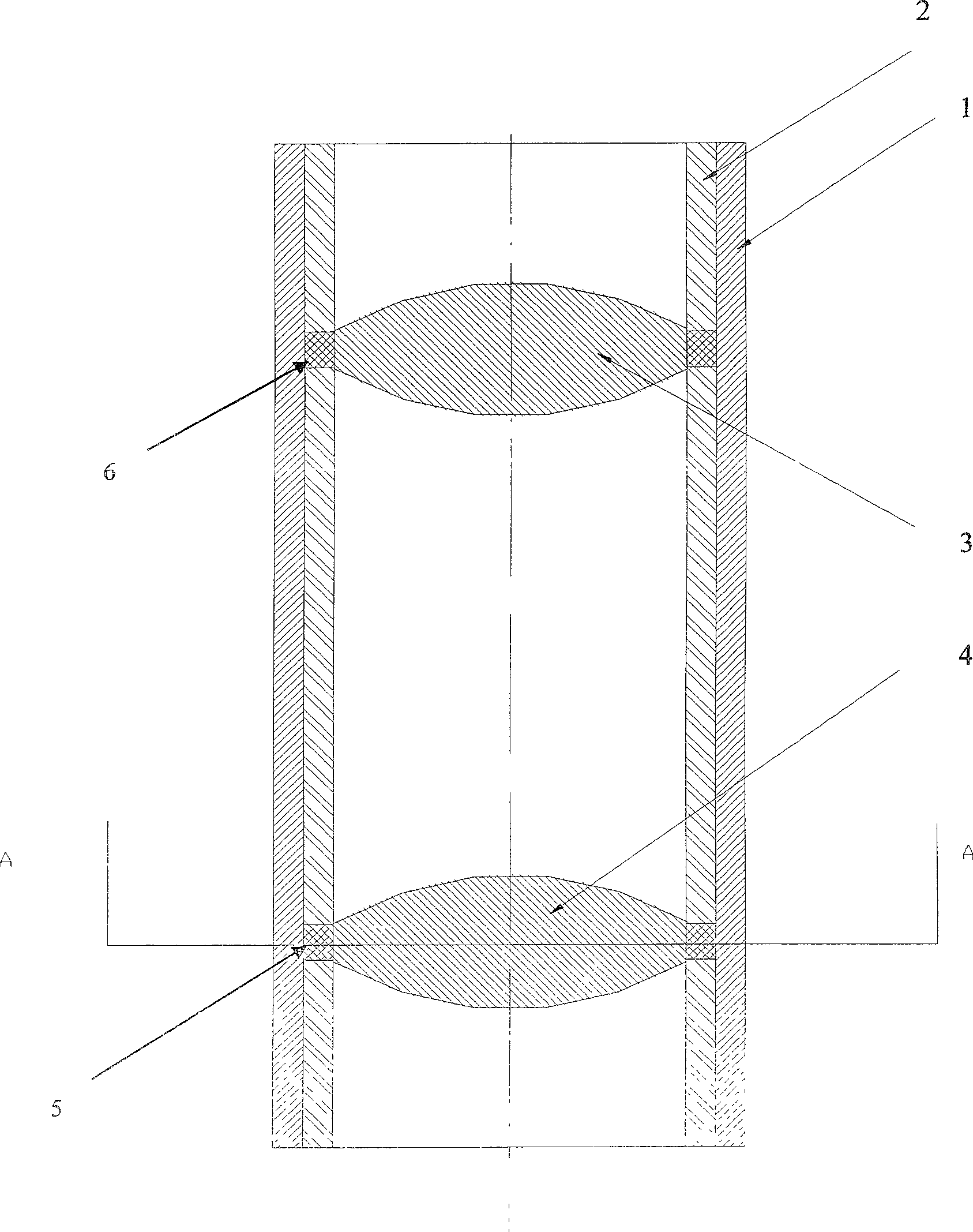

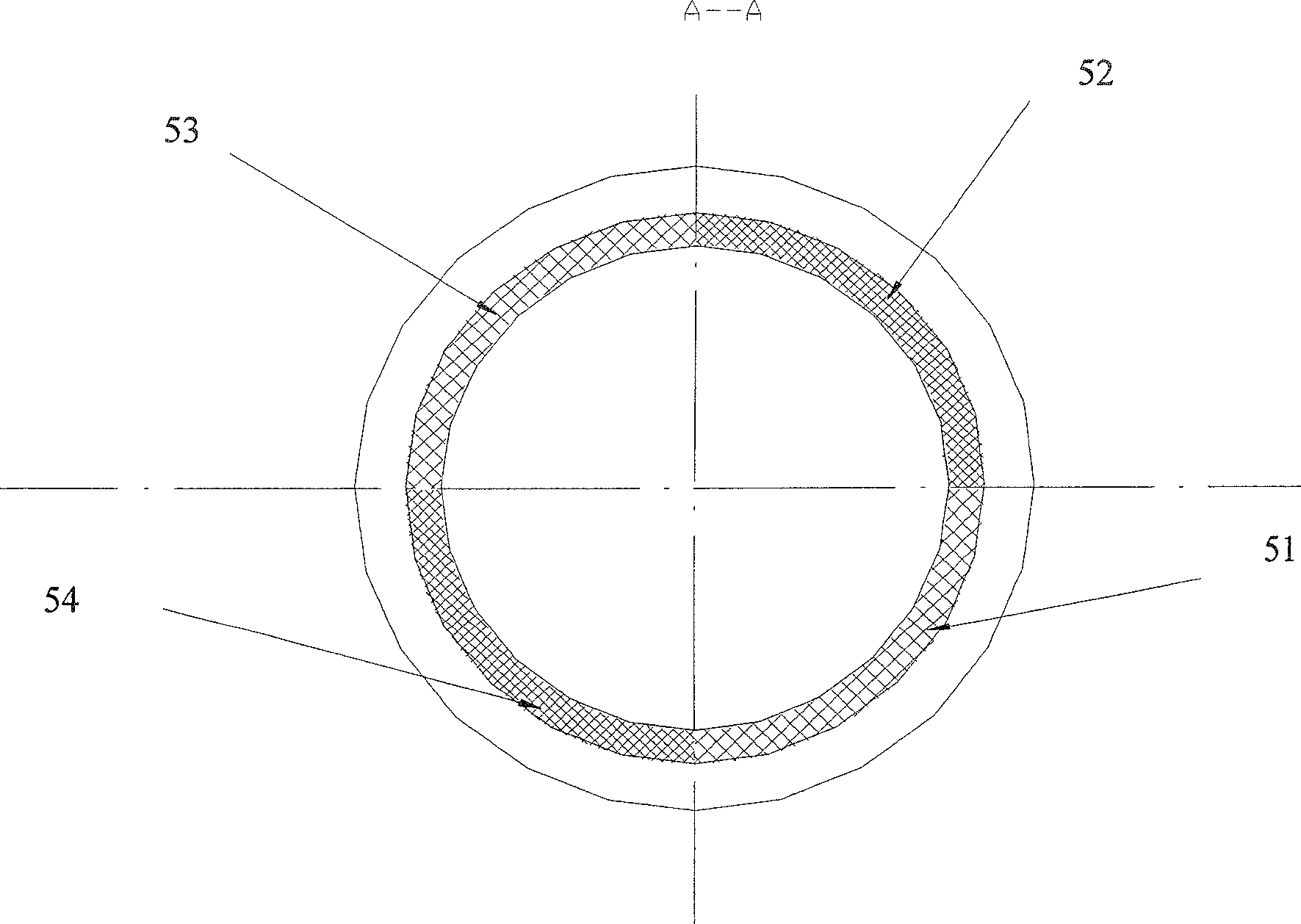

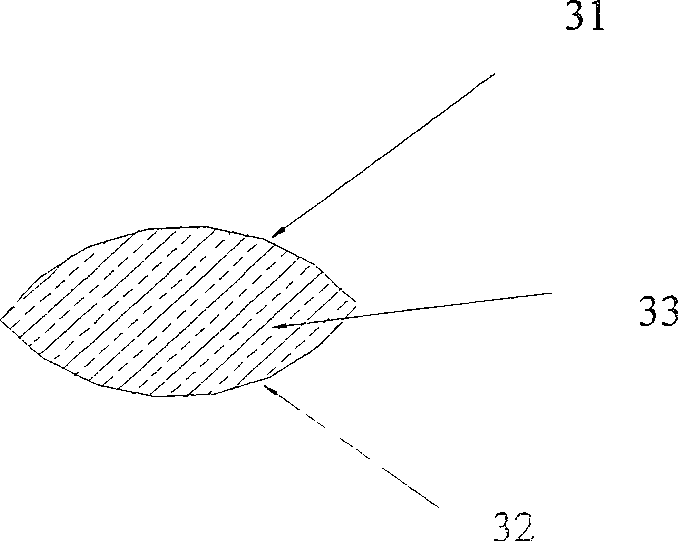

[0028] The embodiments of the micro-lens lens group with adjustable focal length and field of view of the present invention are as follows: 1) Micro-injection method is used to form a micro-fluid micro-cavity in PDMS or other transparent films. The specific manufacturing process is as follows: Figure 4 As shown, the planar layout of the obtained microcavity is as Figure 5 As shown; 2) After the bonding of PDMS adopts general plasma treatment (oxygen at 100---1500W, microwave plasma treatment device with a vacuum of about 500 Torr for 15-60 minutes) pressure bonding (pressure about 1000 Pa); 3) Inject liquid or water into the cavity with a syringe and seal the injection port with the PDMS film treated with oxygen plasma (the maximum pressure of the cavity is about 10 Psi); 4) Apply voltage (0-450V) to the piezoelectric film (PVDF) outside the PDMS microcavity , Or apply driving voltage (0-450V) to the original ring piezoelectric ceramics and axial piezoelectric ceramics (PZT) to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com