Infrared ultrafast laser stainless steel surface gray scale marking system

A stainless steel and infrared super technology, applied in laser welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of high roughness of pattern marks, difficult control of overall uniformity, low photon resolution, etc., and achieve consistent Good consistency, high consistency, high resolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

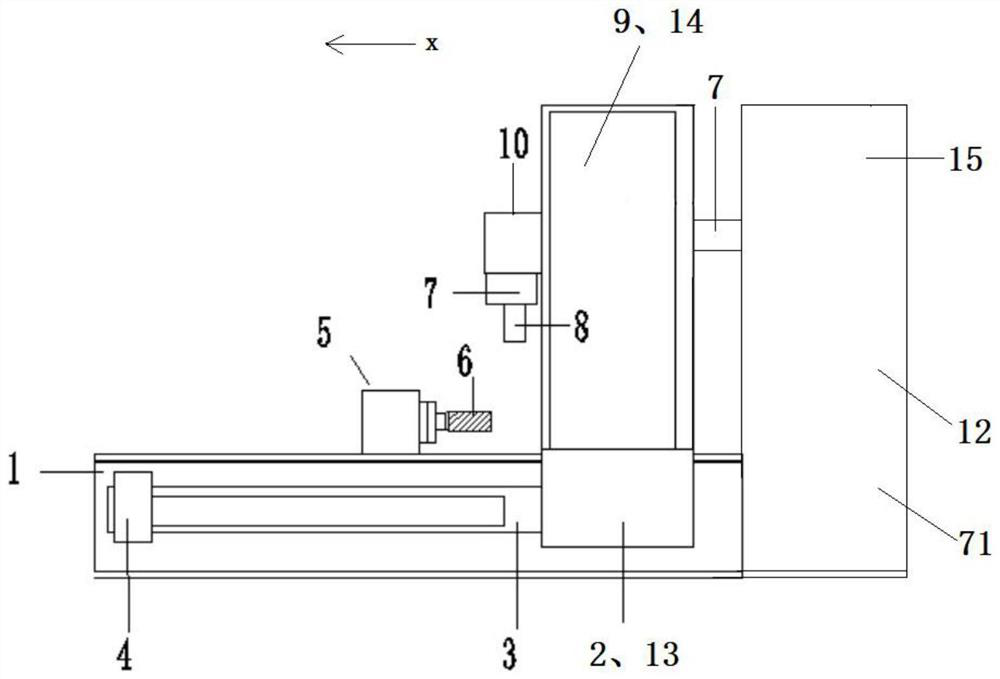

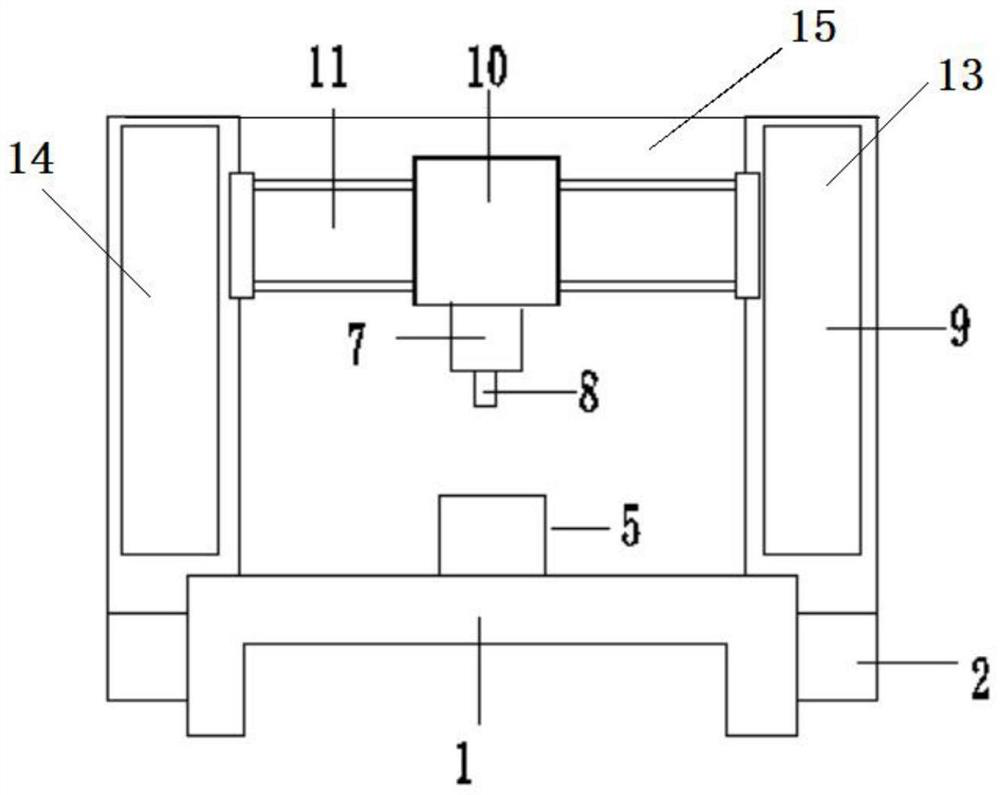

[0049] This embodiment is an example of marking a stainless steel water cup in the infrared ultrafast laser stainless steel surface grayscale marking system of the present invention, and its specific structure is as follows:

[0050] Including a workbench 1 and a laser 71, the laser 71 is an all-solid-state picosecond laser;

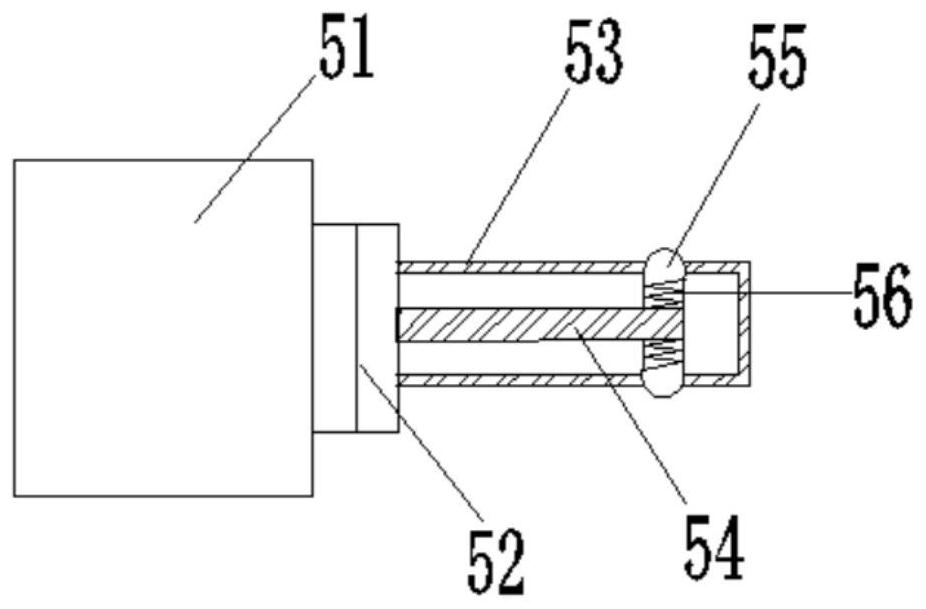

[0051] The worktable 1 is provided with an X-axis moving mechanism 13, and the X-axis moving mechanism 13 includes a gantry frame 14 and first slide rails 3 arranged on both sides of the workbench 1; first slide rails 3 on both sides are provided with first The slider 2 and the bottom ends of the two columns 9 of the gantry 14 are respectively connected to the first sliders 2 on both sides, and the two sides of the workbench 1 are respectively provided with a first drive 4, and the two first drives 4 are respectively The first slider 2 for driving the corresponding side moves along the corresponding first slide rail 3 to realize the X-axis movement; the ...

Embodiment 2

[0060] It is basically the same as Example 1, the difference is that the marking is done on the stainless steel disc workpiece, and the marking effect can be found in Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com