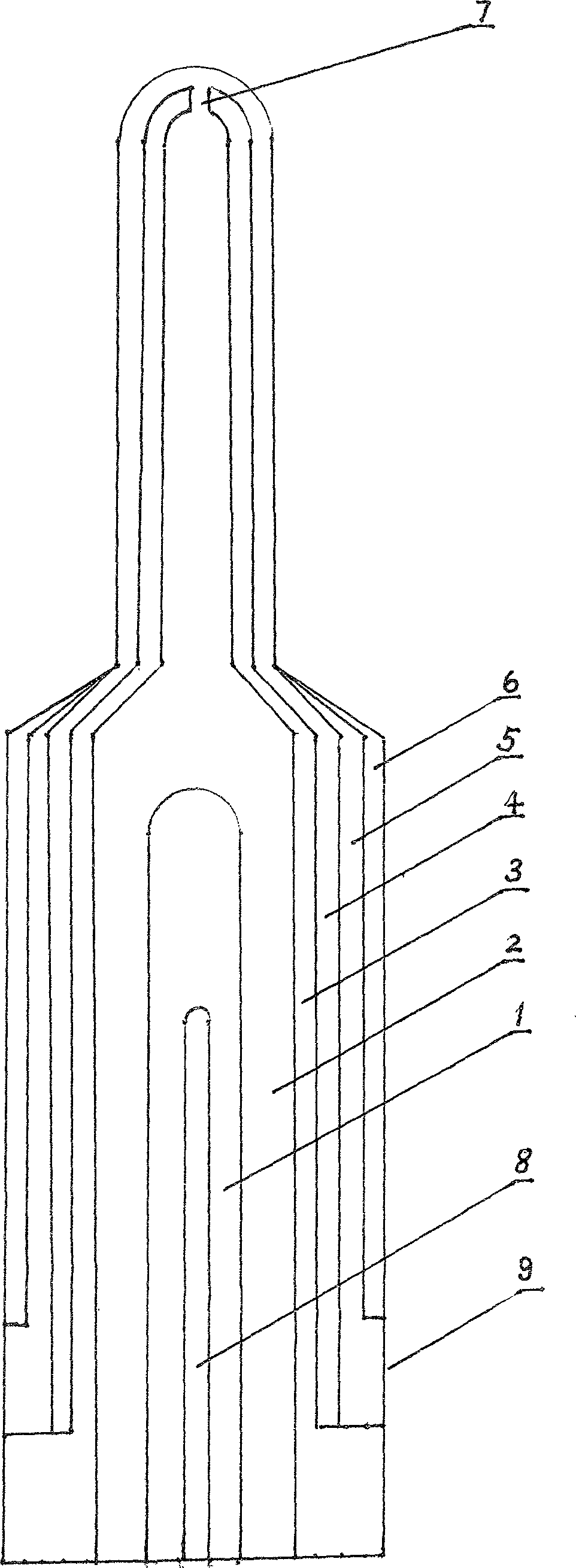

Six-layered structure all-ceramic electric heater

A technology of electric heating body and layer structure, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of many processing procedures, poor anti-seismic ability, small distance, etc., and achieve reduced production procedures, high anti-seismic strength and fast speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0008] The specific implementation is as follows: the inner conductive layer 1 is located at the center of the electric heating body, and the central electrode jack 8 is located at the center of the inner conductive layer 1; The lower section is wrapped outside the inner conductive layer 1; the inner insulating layer 3 is divided into three sections, the diameter of the middle section is larger than that of the upper section, the diameter of the lower section is larger than that of the middle section, the upper section is wrapped outside the upper section of the inner resistance layer 2, and the middle section and the lower section are wrapped in the inner resistance layer. 2 outside the lower section; the outer resistance layer 4 is divided into two sections, the upper section is wrapped outside the upper section of the inner insulating layer 3, the lower section is wrapped outside the middle section of the inner insulating layer 3, and the diameter of the lower section is smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com