Hollow tooth-shape fluidized filling

A hollow, tooth-shaped technology, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems that affect the wide application of biological carrier fillers, unreasonable structural strength design, and unsatisfactory adsorption capacity and other problems, to achieve the effect of reasonable structural strength design, simple structure, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

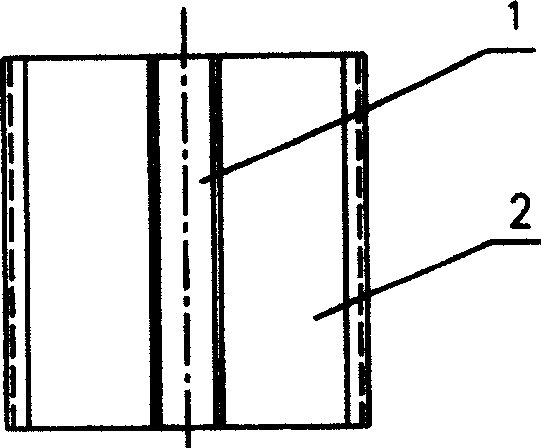

[0028] refer to figure 1 , figure 2 , image 3 As shown, a hollow tooth-shaped fluidized filler includes a body 1, teeth 2, etc.; the body 1 is hollow, with the center of the tooth shape as the center, and teeth 2 are evenly distributed on the body 1, and the number of teeth 2 is at least There are 3 pieces, preferably 3-16 pieces. The diameter of the addendum circle of the teeth 2 is 20-200mm, and the diameter of the root circle is 10-180mm. According to different water quality requirements, by increasing the number of teeth 2 or adjusting the number of teeth 2. The diameter and size ratio of the addendum circle and the dedendum circle achieve the purpose of adjusting the specific surface area: the axial length and wall thickness of the tooth 2 are equal to the length and thickness of the body 1, and the length is 20-200mm. It can be cut into segments according to actual needs. shape, the wall thickness is 0.5-1.5mm, the outer diameter of the teeth 2 is 20-200mm, and the c...

Embodiment 2

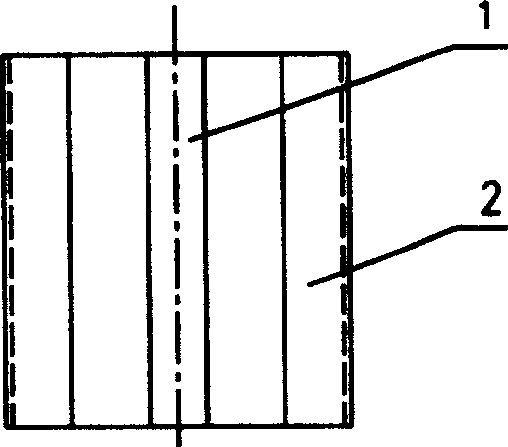

[0030] refer to Figure 4 , Figure 5 , Image 6 As shown, the overall shape of the body 1 and the teeth 2 can also be in the shape of a hollow triangular gear, and the cross-section of each tooth 2 is in the shape of a triangular tooth. All the other structures are with embodiment 1.

Embodiment 3

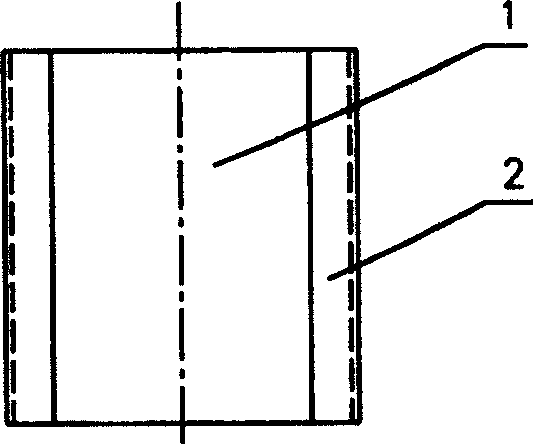

[0032] refer to Figure 7 , Figure 8 , Figure 9 As shown, the overall shape of the body 1 and the teeth 2 can also be in the shape of a hollow arc gear, and the cross section of each tooth 2 is in the shape of an arc tooth, which smoothly transitions with the corners of the polygonal body 1 . All the other structures are with embodiment 1.

[0033] When the present invention is used, it is directly added to the water treatment structure, and through the multi-directional force of the water flow and air bubbles on the teeth 2, it can fully drive the body 1 to realize rotation and flow in various angles and directions in the water, thereby strengthening the Mass transfer between water, air and microorganisms and on fluidized packing. The fluidized filler will make it easier for the biological community mainly composed of microorganisms to grow on the main body 1, the teeth 2 and the peaks and valleys 3 on the inner and outer surfaces, and perform reasonable shedding and ren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com