Pixel structure and its production

A technology of pixel structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of high cost, complicated photoresist bump manufacturing, etc., and achieve the effect of improving reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

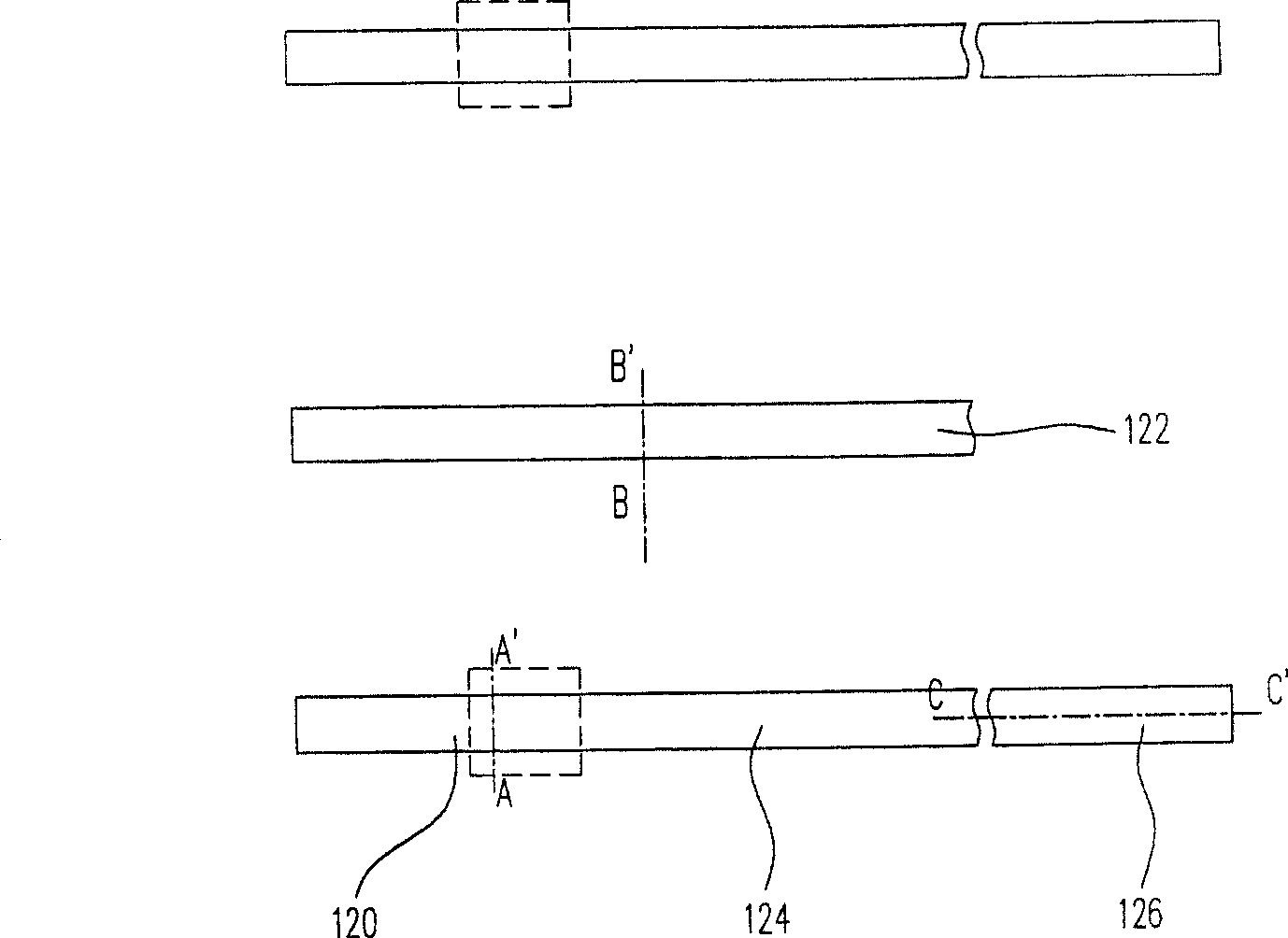

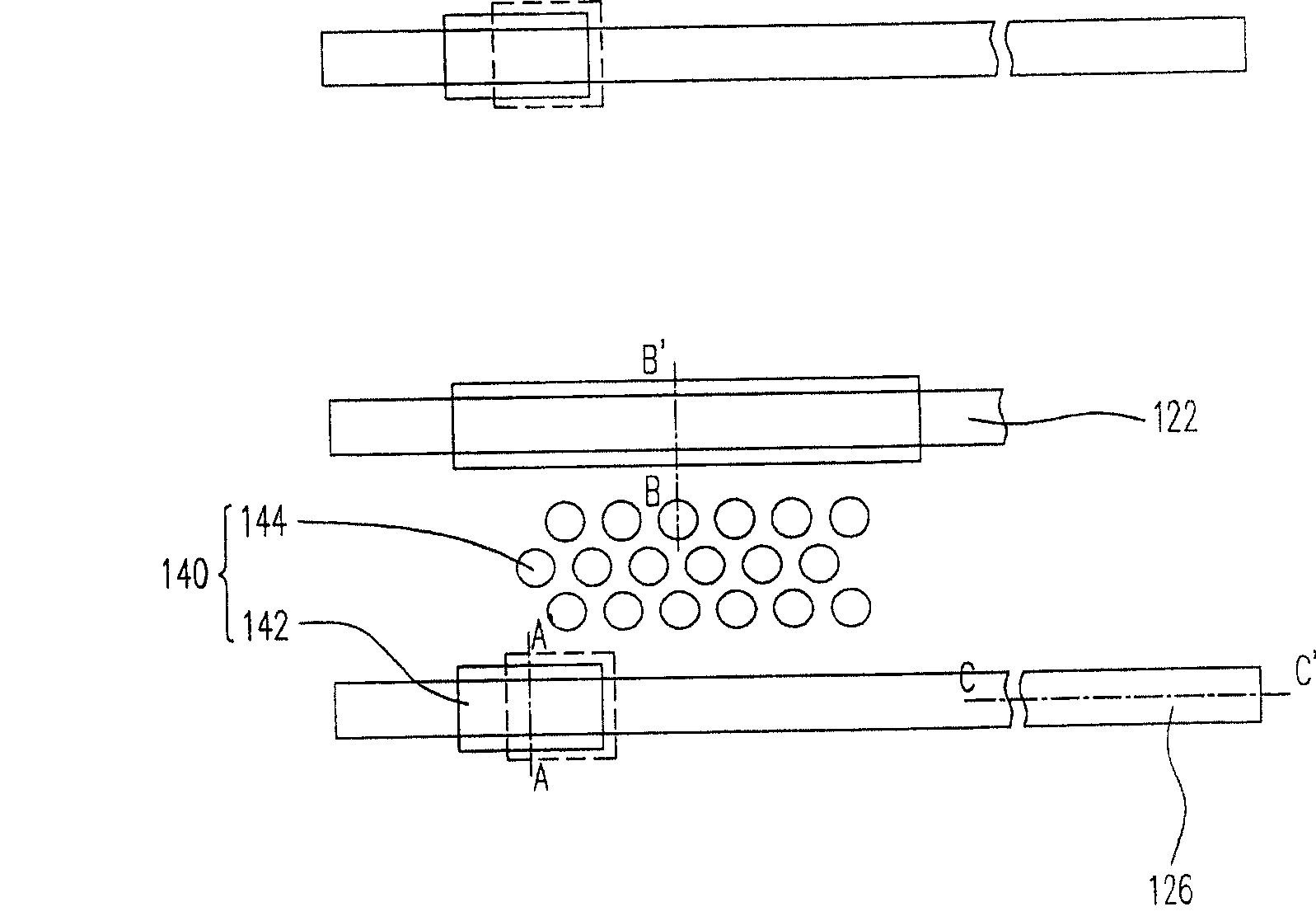

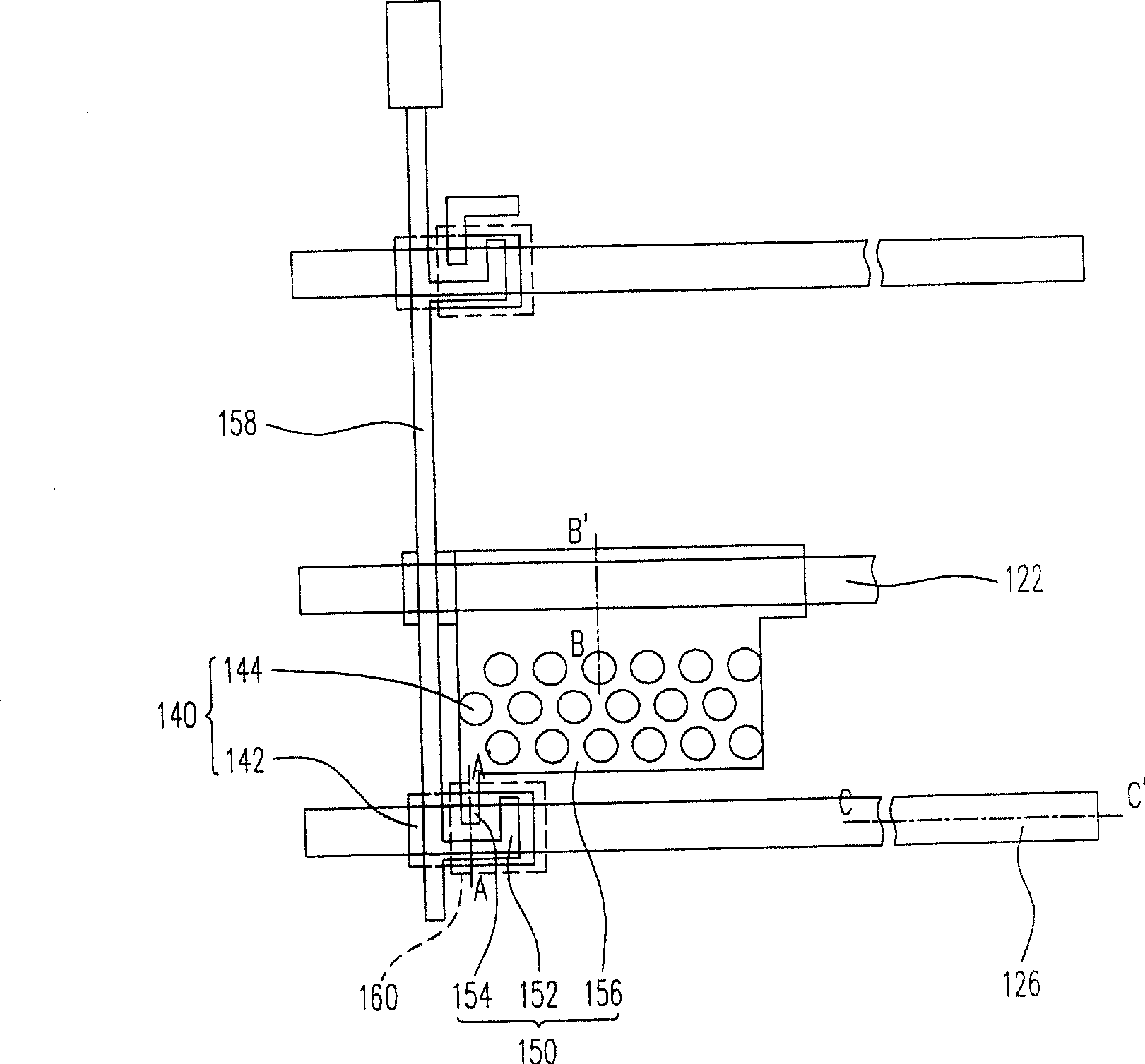

[0057]Generally speaking, disposing reflective pixel electrodes in the pixel structure can make the pixel structure have the ability to reflect light. It has both transmissive and reflective display modes. It can be seen from the description of the prior art that in order to make this type of pixel structure have good quality, a pad layer for padding the reflective pixel electrode and a photoresist bump to improve the reflectivity are usually made in the pixel structure, but this method will lead to The manufacturing process of the pixel structure becomes complicated, which reduces the output and product yield. Therefore, the present invention proposes a method for manufacturing a pixel structure, so as to manufacture a pixel structure with good quality under the premise of simplifying the process complexity.

[0058] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the following specific embodiments are descr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com