Waste plastic and rubber reduction and reducing system

A waste plastic and waste rubber technology, which is applied in the field of waste plastic and rubber recycling, can solve the problems of non-recyclable combustible gas, waste, and unstable process, so as to solve the problem of coking at the bottom of the kettle, improve the efficiency of electricity use, and solve the problem of secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

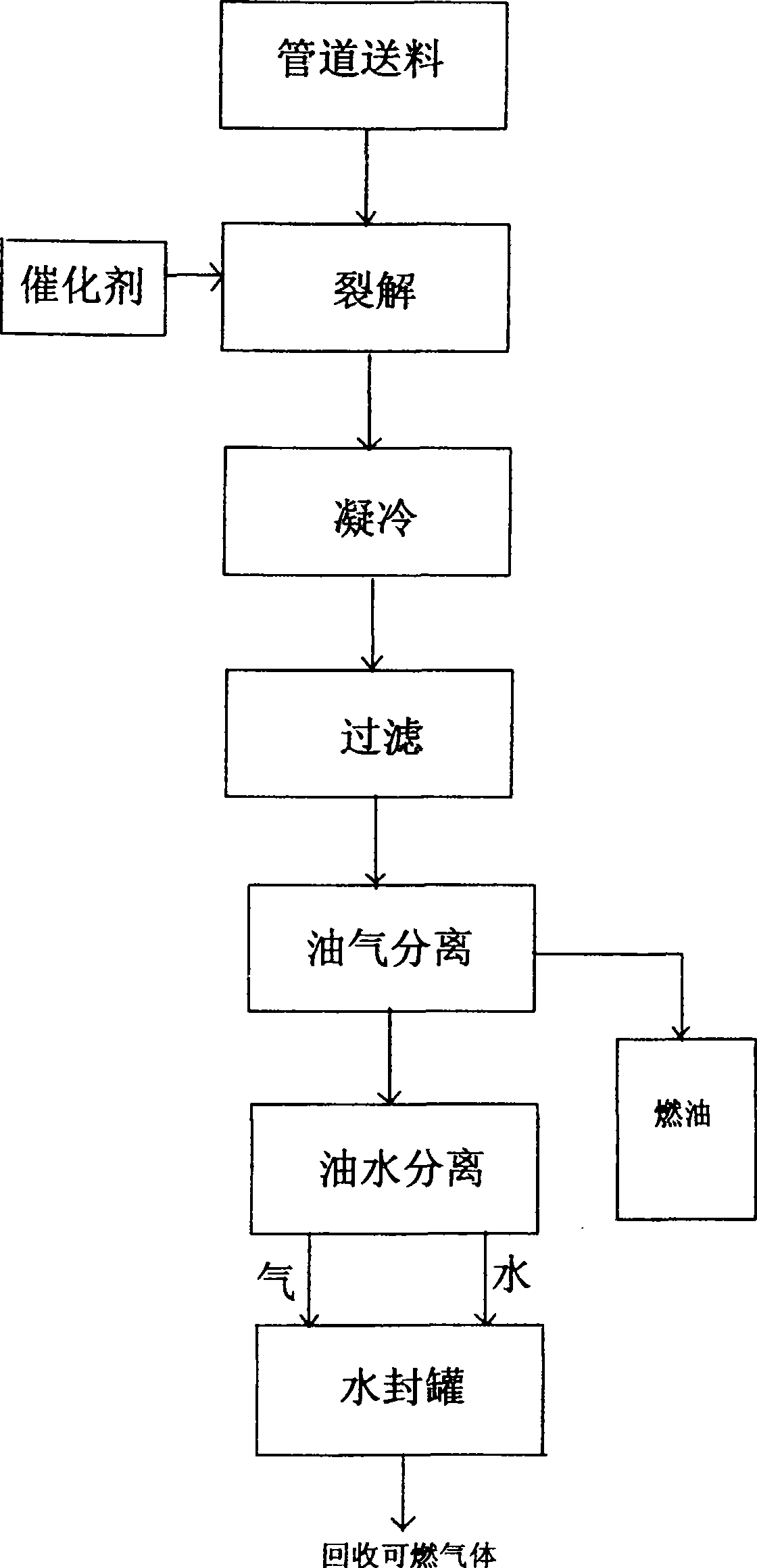

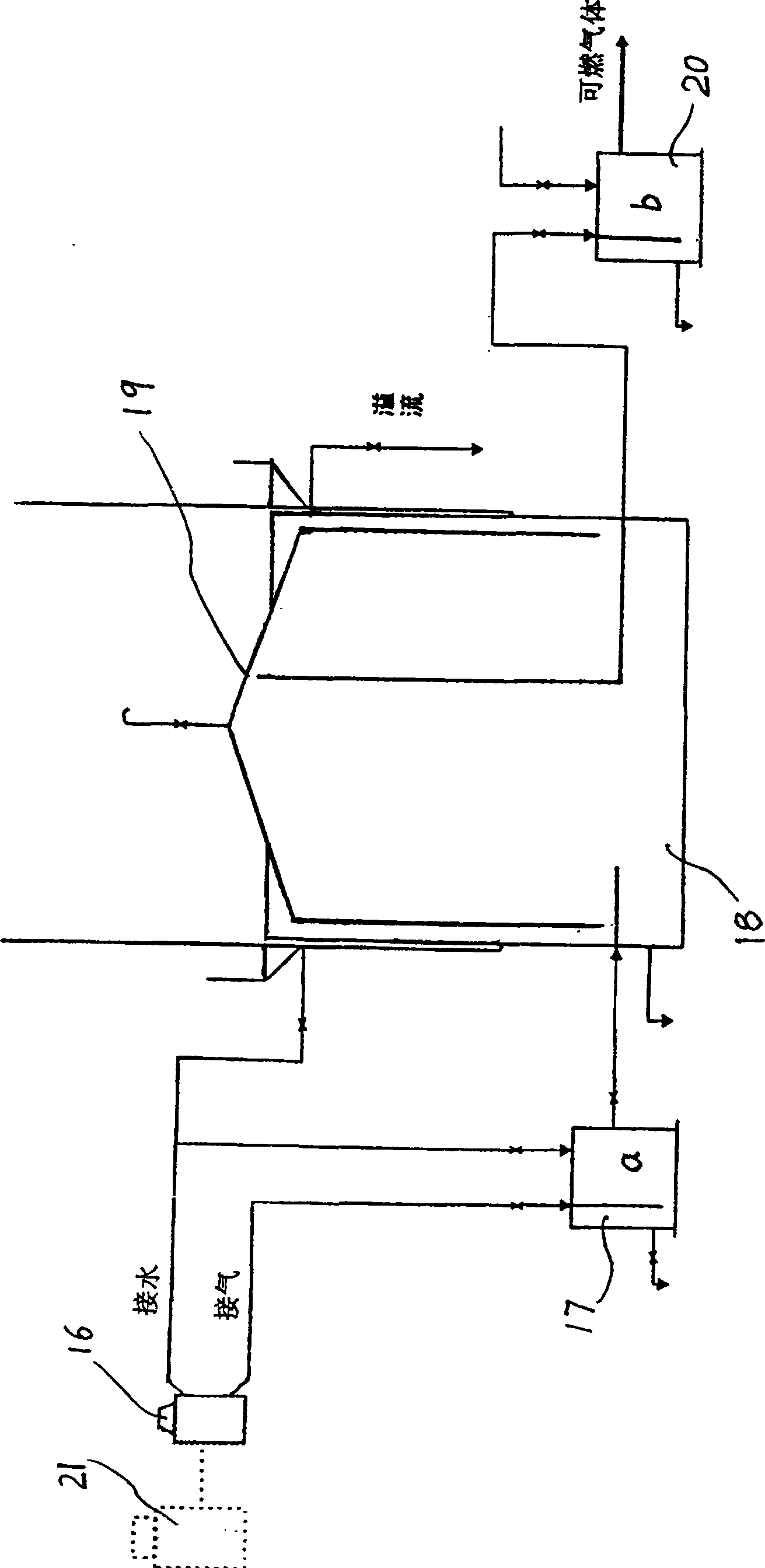

[0034] process flow

[0035] 1. Using waste plastic as raw material

[0036] Raw materials—drying—crushing—feeding—catalysis—cracking—condensation—filtration—products.

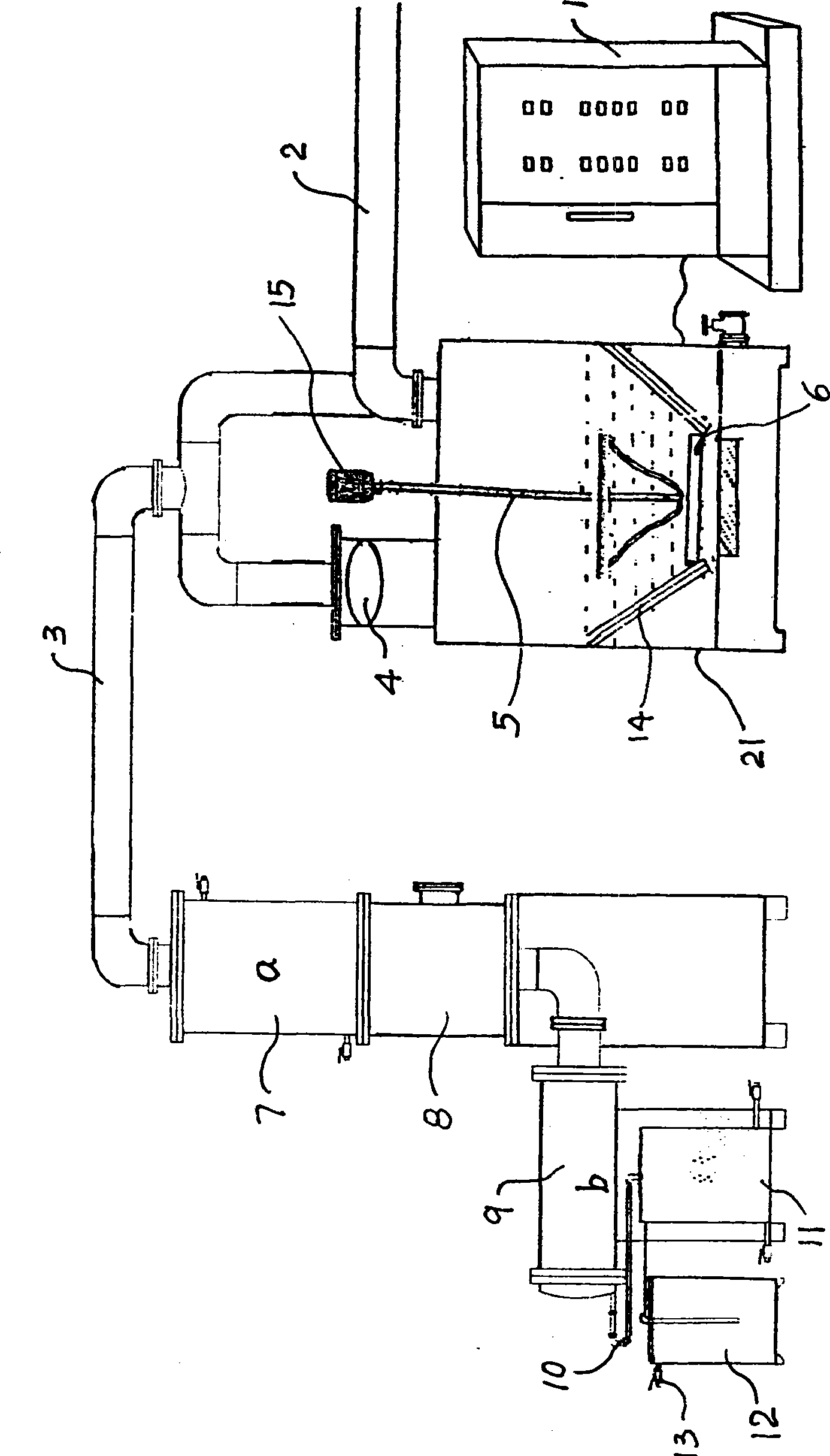

[0037] After the waste plastics are broken, send them into the cracking kettle 21 by means of pipeline 2 air delivery, and at the same time add 1-3‰ natural zeolite according to the weight ratio, and set an electronic induction breaker on the induction frequency conversion closed loop to control the pressure from being too high; temperature control Set the temperature on the device, set the temperature in the upper part of the kettle to 300C, set the temperature in the lower part of the kettle to 420C, and the outer bottom of the kettle to 500C. Keep the temperature in the electric induction cracking kettle at 350C-400C. After the setting is completed, start to heat up at an average speed. Catalytic cracking reaction time is 3-4 hours. During the process of temperature rise, cracking catalytic reaction occurs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com