Electrophoresis application technique method of roll bending material and complete sets

A technology of electrophoretic coating and electrophoresis, which is applied in the direction of electrophoretic plating, coating, electrolytic coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

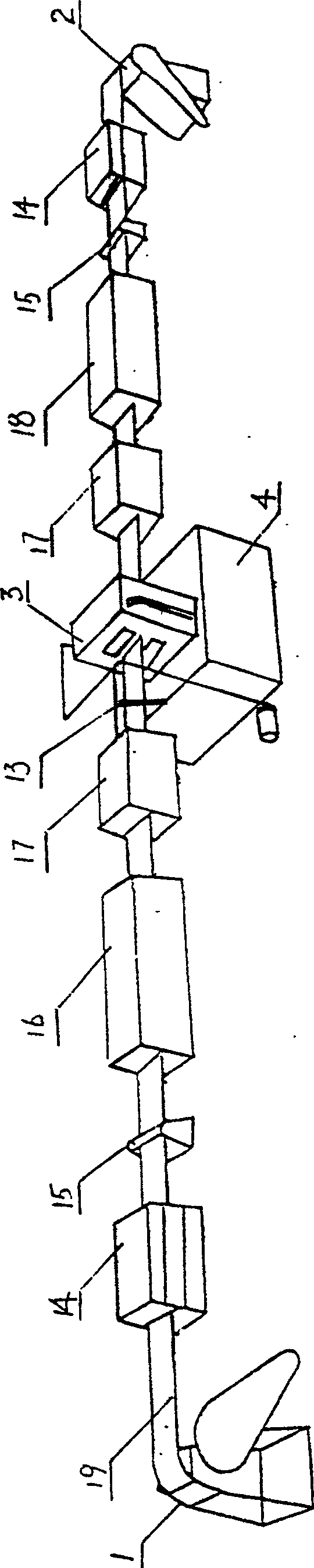

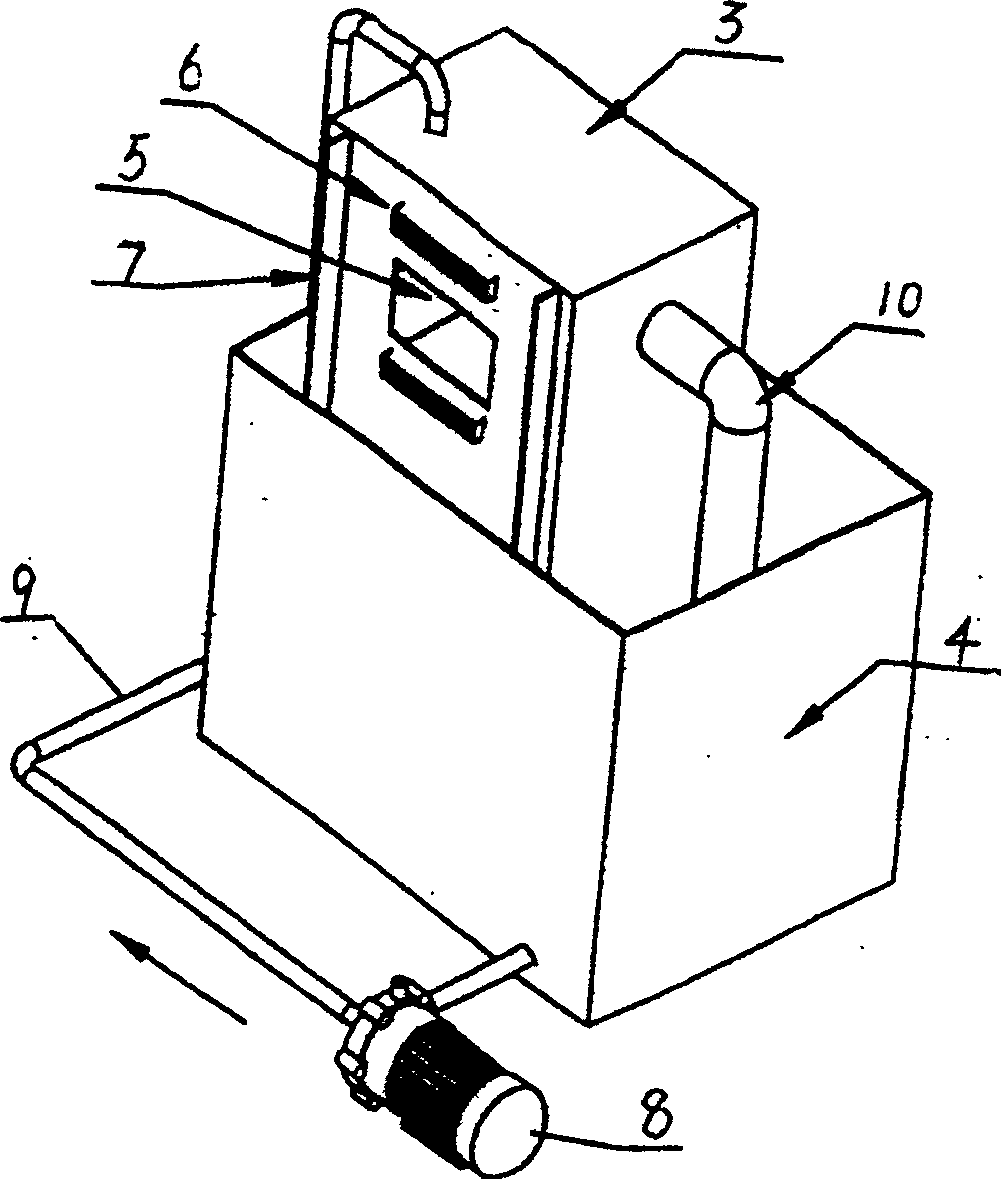

[0039] Embodiment 1: during planar transverse cathodic electrophoresis process:

[0040] The coil material workpiece 19 is the piece to be electrophoresed, which is a cathode system, and is connected to the negative pole (-) of the electrophoresis source through the conductive device 13. The anode system is connected to the positive pole (+) of the power supply. The anode is a fixed connection, and the cathode is crimped or clamped with elastic metal materials, but it cannot affect the continuous movement of the workpiece. Such as figure 1 As shown: the coiled plate workpiece 19 passes through the electrophoretic paint solution in the electrophoresis main tank 4 in parallel, passes the coiled plate material workpiece through the two parallel slot holes of the electrophoresis main tank, starts the mobile transmission power supply, and allows the coiled plate workpiece to move in parallel ; When the coil material workpiece passes through the leveling machine, the workpiece is ...

Embodiment 2

[0048] Embodiment 2: during planar transverse anodic electrophoresis process:

[0049] The coil material workpiece is the electrophoresis part, which is the anode system, connected to the positive electrode (+) of the electrophoresis source. The cathode system is connected to the negative pole of the power supply (-). The cathode is a fixed connection, and the anode is crimped or clamped with elastic metal materials, but it cannot affect the continuous movement of the workpiece. Pass the coil material workpiece through the electrophoretic paint solution in the electrophoresis tank in parallel, and pass the coil material workpiece through the two parallel slot holes of the electrophoresis tank. Start the mobile transmission power supply to make the coiled workpiece move in parallel. When the coiled plate material workpiece passes through the leveling machine, the workpiece is leveled and evened by leveling, and the workpiece is conveyed to the next process. When the coil mat...

Embodiment 3

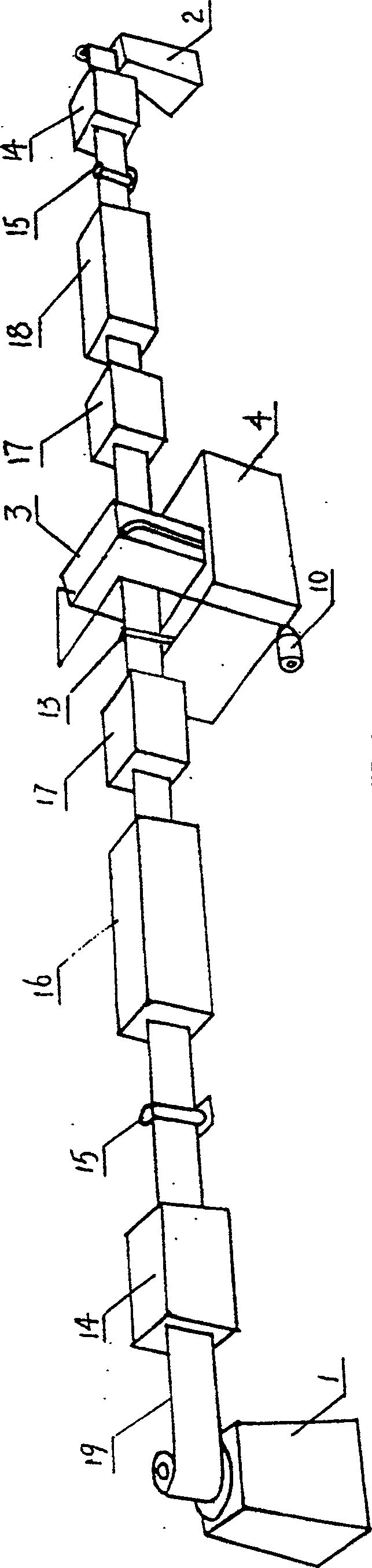

[0051] Embodiment 3: When vertical cathodic electrophoresis process is erected: the coiled plate material workpiece is the electrophoresed part, which is the cathode system, connected to the negative electrode (-) of the electrophoresis source. The anode system is connected to the positive pole (+) of the power supply. The anode is a fixed connection, and the cathode is crimped or clamped with elastic metal materials, but it cannot affect the continuous movement of the workpiece. Such as figure 2 Shown: the coiled plate material workpiece is vertically passed through the electrophoretic paint solution of the electrophoresis tank, and the coiled plate material workpiece is passed through the two vertical vertical slot holes of the electrophoresis tank. Start the mobile transmission power supply to allow the coiled workpiece to move vertically. When the coiled plate material workpiece passes through the leveling machine, the workpiece is leveled and evened by leveling, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com