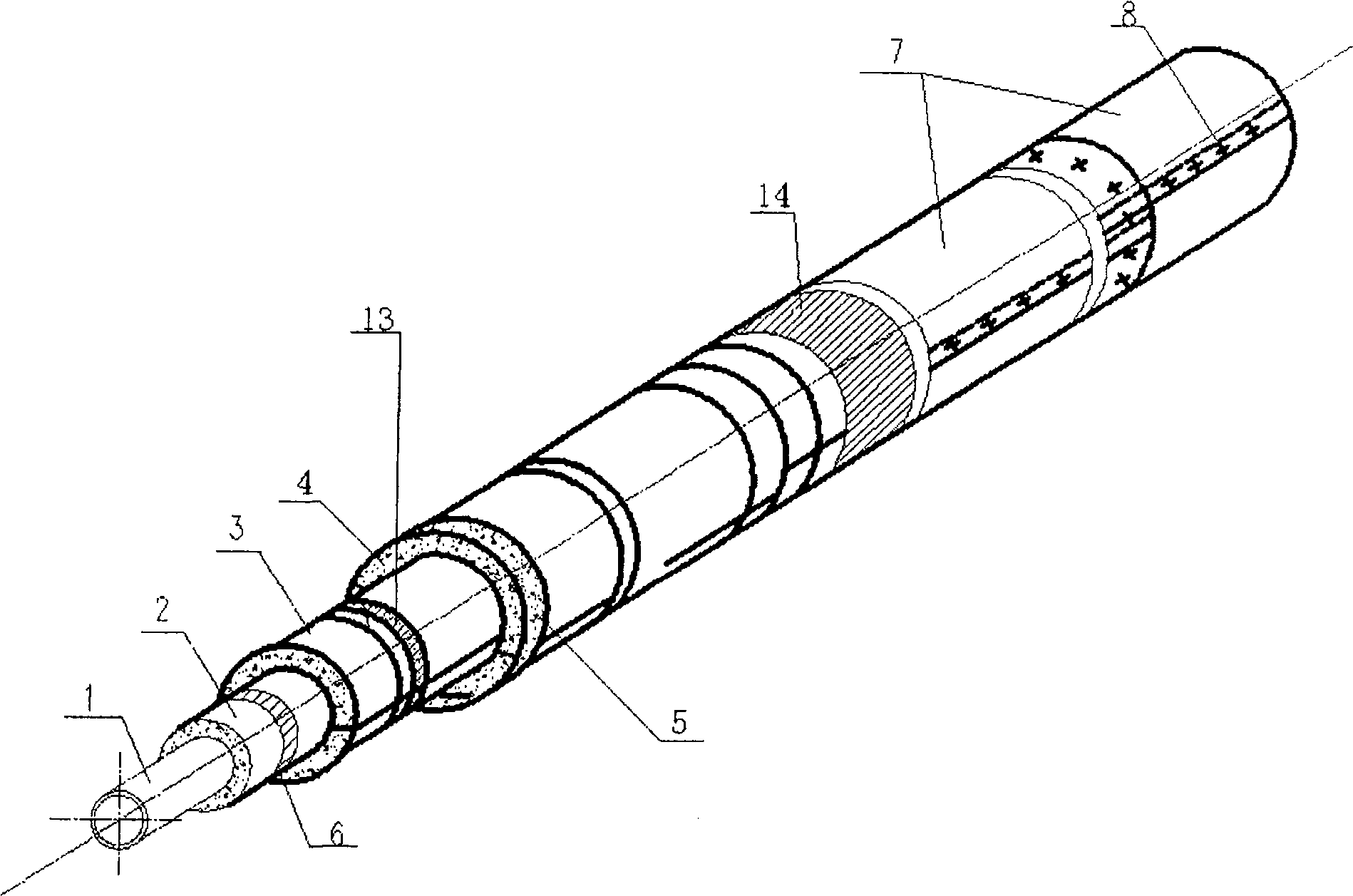

Long heat transportation net method

A heating network, long-distance transmission technology, applied in heating methods, household heating, heating systems, etc., can solve the problems of limited heating radius, large heat loss, large temperature drop, etc., to reduce production costs and ensure heating parameters, the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

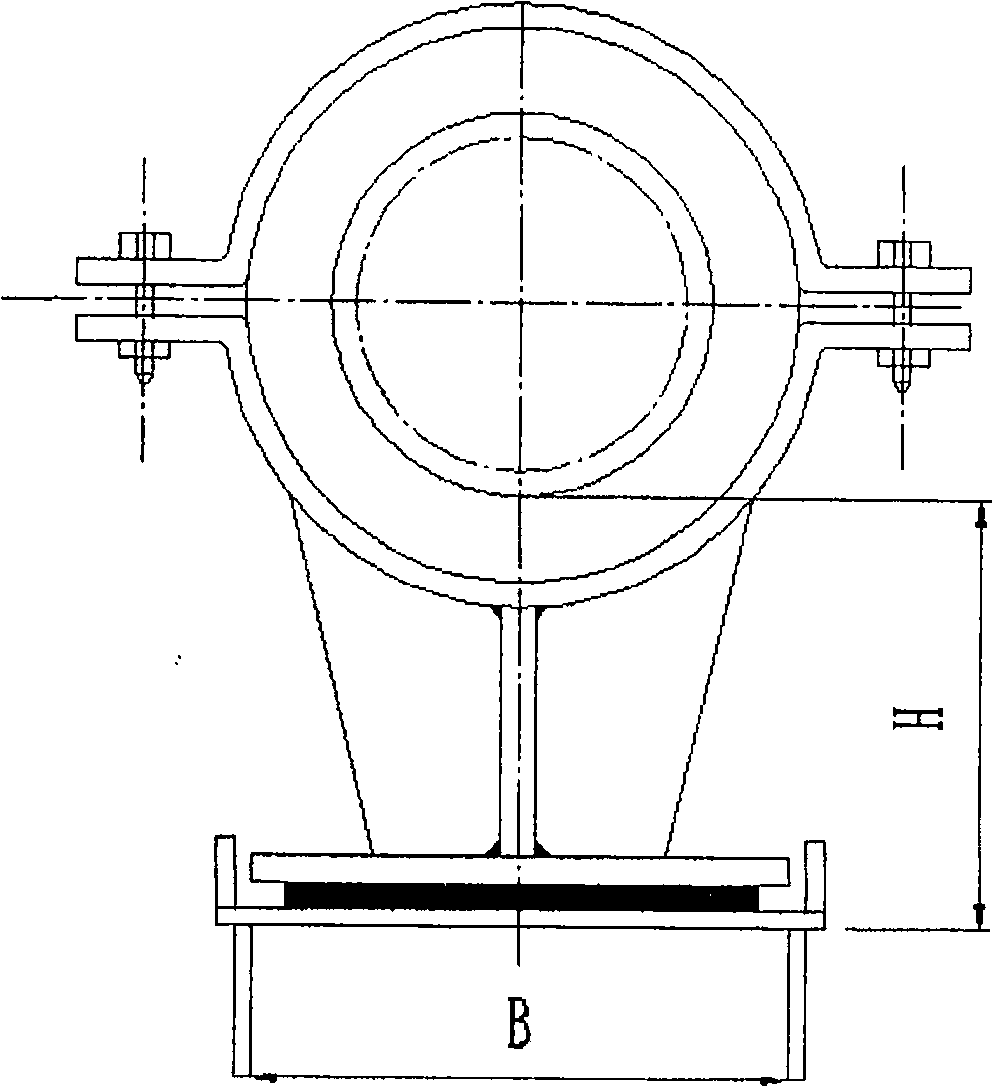

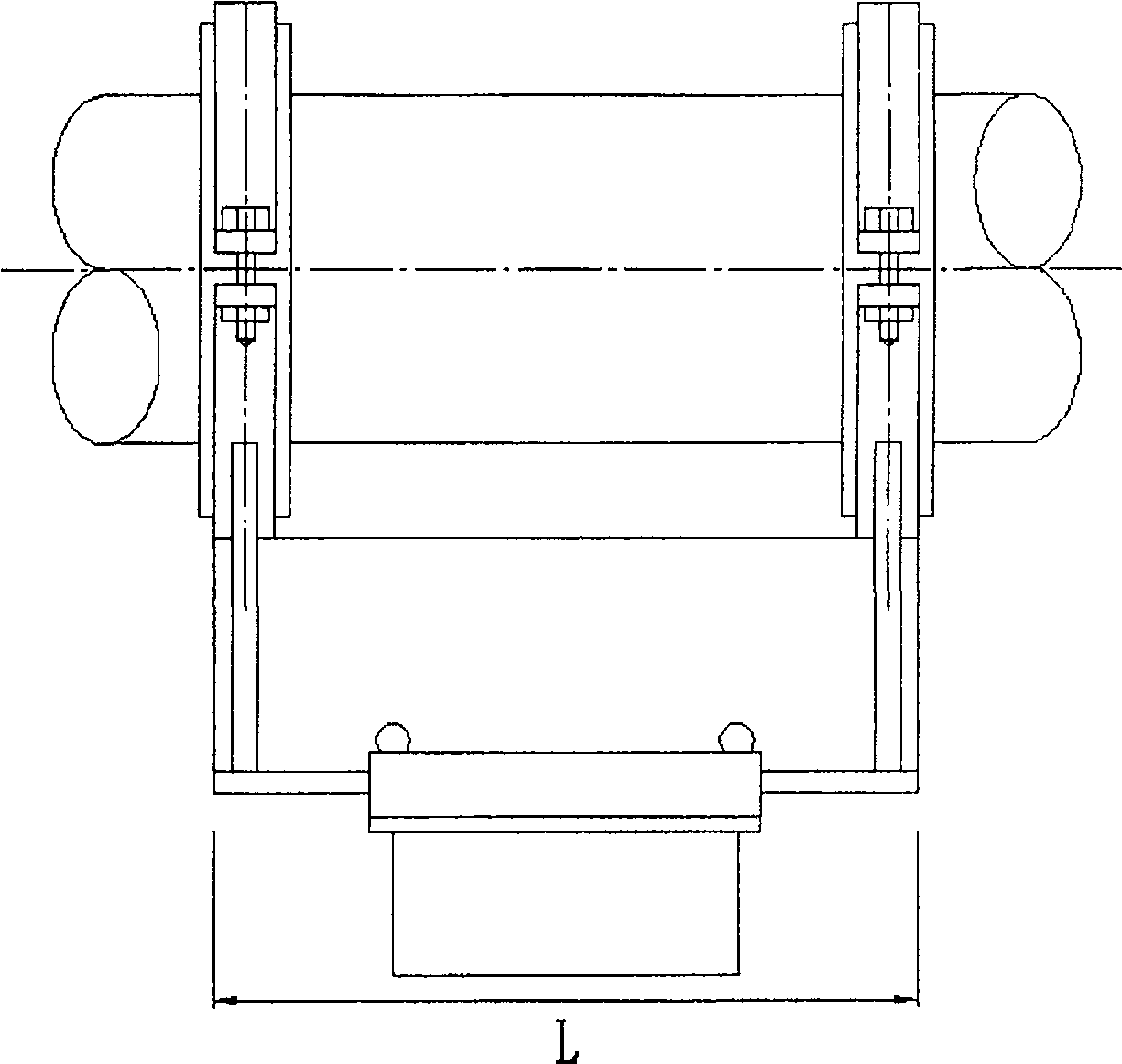

Method used

Image

Examples

Embodiment 1

[0045] The total length of a pipeline single line (start point to end point) in a certain place is about 18.5 kilometers. If the outlet pressure of the thermal power plant is 0.94Mpa, the temperature is 300°C, and the flow rate is 18t / h (30% of the design load), the long-distance heating network method of the present invention is adopted. After calculation, the end-user pressure can reach 0.84MPa, the temperature reaches 178.3°C, and the temperature drop per kilometer is about 6.58°C; when the flow rate reaches 25t / h (40% of the design load), the end-user pressure can reach The temperature reaches 0.8MPa, the temperature reaches 183°C, and the temperature drop per kilometer is about 6.32°C; when the flow rate reaches 40t / h, the pressure to the end user can reach 0.75MPa, the temperature reaches 188°C, and the temperature drop per kilometer is about 6°C. As long as the end user requires the pressure to be greater than 0.5MPa and the temperature to be greater than 165°C to meet t...

Embodiment 2

[0047] The total length of a single pipeline (from the starting point to the end point) in a certain place is about 13.5 kilometers. Using the technical solution of the present invention, if the outlet pressure of the thermal power plant is 0.96Mpa, the temperature is 288°C, and the flow rate is 15t / h (25% of the design load), the calculated : When the end user reaches 12.5 kilometers away, the pressure can reach 0.85MPa, the temperature can reach 198.5℃, and the temperature drop per kilometer is about 6.63℃; The temperature drop was about 6.15°C.

[0048] The invention can greatly expand the heat supply range of thermoelectric enterprises, so that enterprises far away from thermal power plants can also apply to central heating, remove small boilers, effectively reduce coal consumption, increase heat-to-electricity ratio, reduce sulfur dioxide emissions, and protect the environment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com