Pressure reducing valve and gas regulator

A pressure reducing valve and regulator technology, applied in pressure lubricants, machines/engines, fluid pressure control without auxiliary power, etc. The effect of cost reduction, assemblability and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

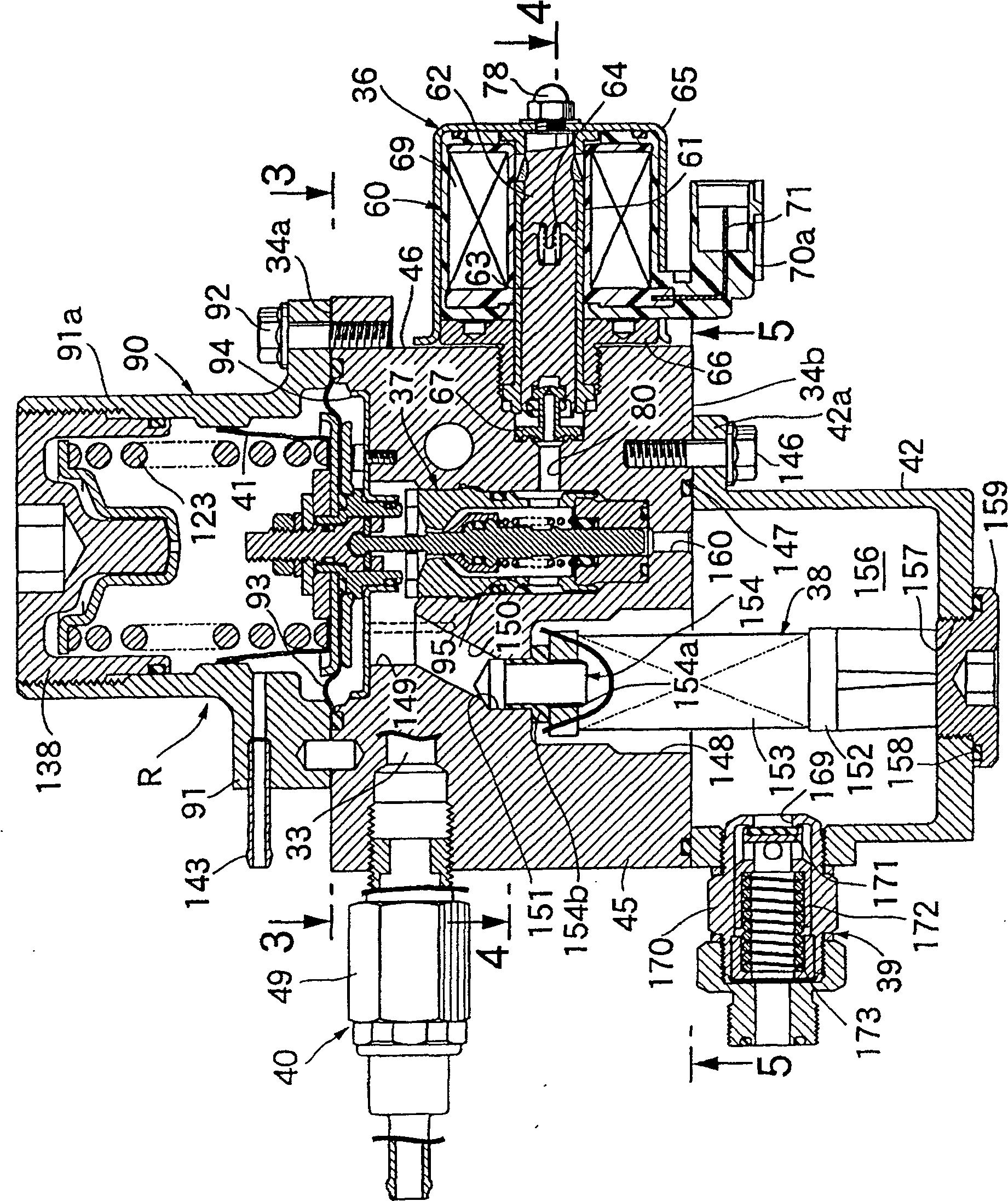

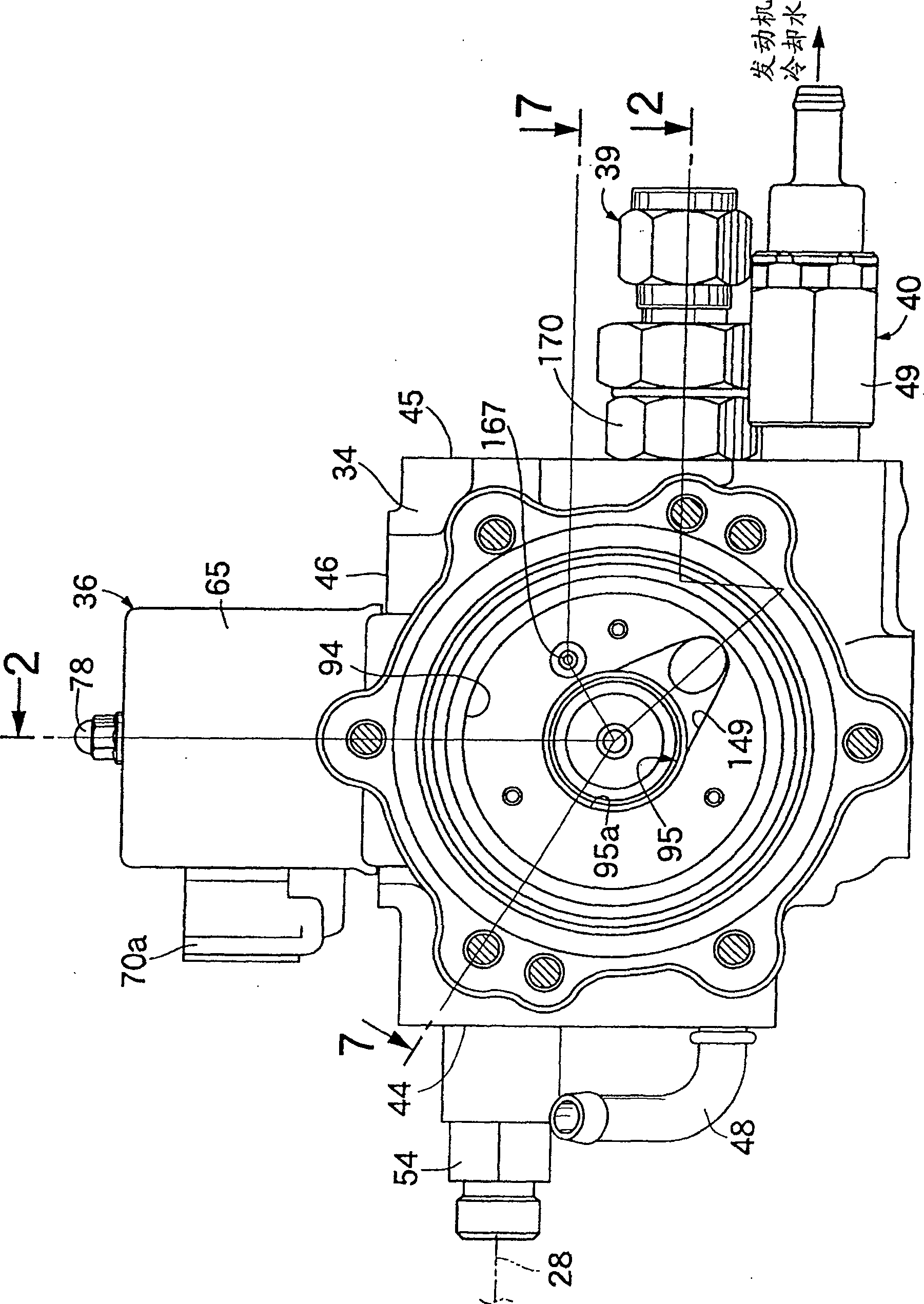

[0048] Figure 1 to Figure 11 shows an embodiment of the present invention.

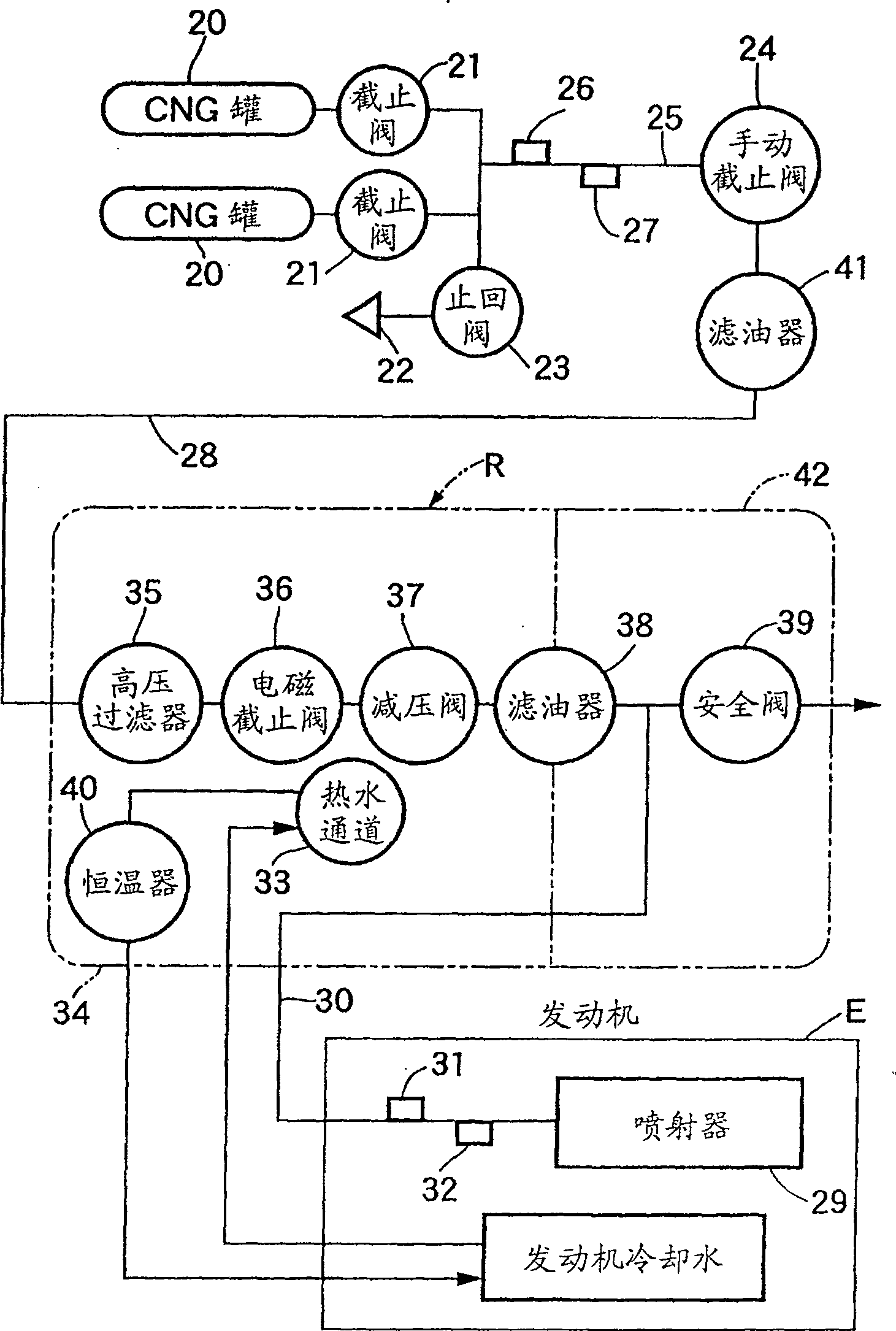

[0049] first in figure 1 Among them, compressed natural gas (Compressed Natural Gas: hereinafter referred to as CNG) as a fuel gas is stored in one or more CNG tanks 20 at a high pressure of, for example, 25 to 1 MPa. These CNG tanks 20 respectively have container shutoff valves 21, They are commonly connected to the filling port 22 via a check valve 23 and to a manual shutoff valve 24 , and a pressure sensor 26 and a temperature sensor 27 are additionally provided in a pipe 25 between each container shutoff valve 21 and the manual shutoff valve 24 .

[0050] When the container shut-off valve 21 and the manual shut-off valve 24 are opened, the CNG from the above-mentioned CNG tank 20 is guided to the gas regulator R through the high-pressure pipeline 28 having an oil filter 41 for removing The oil that may be mixed when the compressor fills the CNG tank 20 with CNG is depressurized by the regulator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com