Deep treatment process of metallurgical sewage

An advanced treatment and sewage technology, applied in the field of advanced treatment of metallurgical sewage and COD reduction, can solve the problems of high one-time investment in process equipment, large fluctuations in water quality indicators, complex components, etc., achieving significant economic benefits, reducing the number of chemical cleaning, The effect of reducing COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

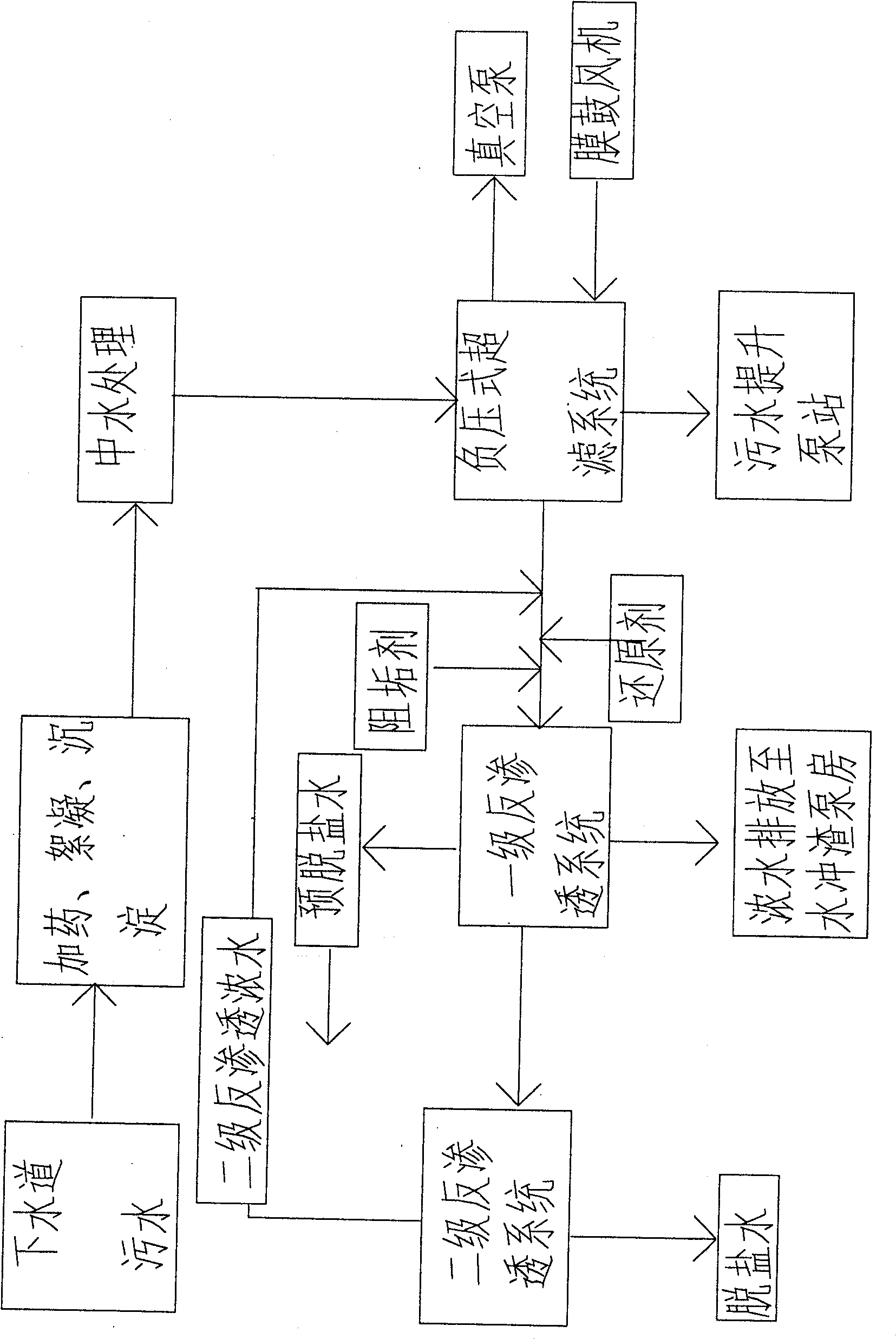

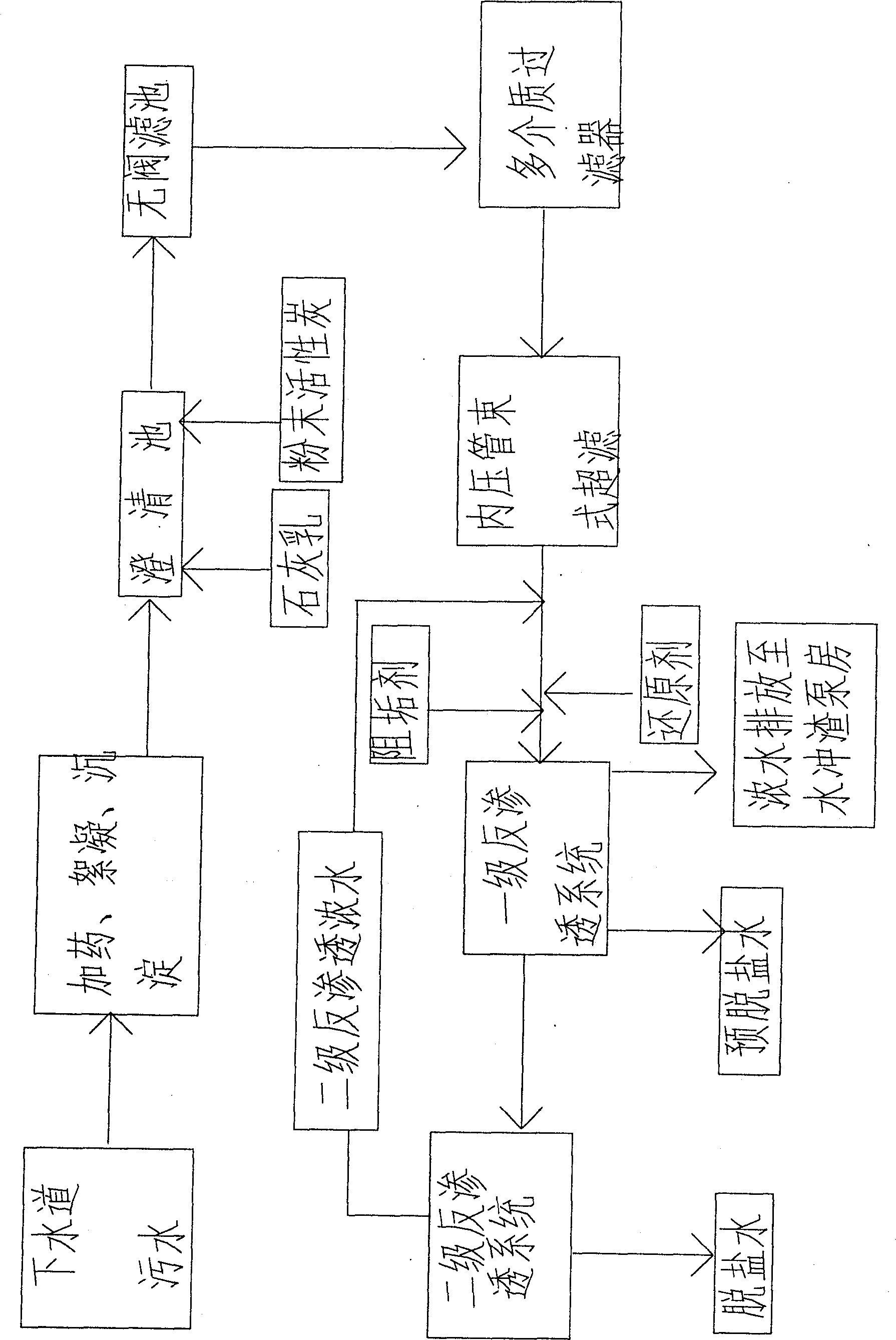

[0042] A. Recycling sewage and producing reclaimed water: collecting and extracting sewer sewage from the metallurgical industry through flocculation and sedimentation to meet the reclaimed water requirement that the effluent suspended matter is less than 100mg / l.

[0043] B. Treatment of reclaimed water to reduce the content of COD and high-valent ions: introduce the above reclaimed water into the clarification tank, according to the water quality, the COD of metallurgical wastewater is 108mg / l, put in lime milk at 100mg / l, and put in powdered activated carbon, lime milk and 20mg / l Powdered activated carbon adopts a complete set of dosing devices including dry speculation, dissolution tank, metering pump and matching pipes and valves. Through the mixing, reaction, flocculation, precipitation, clarification, separation, adsorption, and filtration of clarifiers, valveless filters, and multi-media filters, some suspended solids, colloidal substances, organic substances, oils, alk...

Embodiment 2

[0047] A. Recycling sewage and producing reclaimed water: collecting and extracting sewer sewage from the metallurgical industry through flocculation and sedimentation to meet the reclaimed water requirement that the effluent suspended matter is less than 100mg / l.

[0048] B. Reclaimed water treatment to reduce COD and high-valent ion content: introduce the above reclaimed water into the clarification tank, and according to the water quality, when the COD of metallurgical wastewater is 120mg / l, put lime milk at 150mg / l, powdered activated carbon and lime milk at 30mg / l A complete set of dosing devices are used with powdered activated carbon, including dry speculation, dissolution tank, metering pump and matching pipes and valves. Through the mixing, reaction, flocculation, precipitation, clarification, separation, adsorption, and filtration of clarifiers, valveless filters, and multi-media filters, some suspended solids, colloidal substances, organic substances, oils, alkalinit...

Embodiment 3

[0052] A. Recycling sewage and producing reclaimed water: collecting and extracting sewer sewage from the metallurgical industry through flocculation and sedimentation to meet the reclaimed water requirement that the effluent suspended matter is less than 100mg / l.

[0053] B. Reclaimed water treatment to reduce COD and high-valent ion content: introduce the above reclaimed water into the clarification tank, according to the water quality, when the COD of metallurgical wastewater is 112mg / l, put lime milk at 120mg / l, powdered activated carbon and lime milk at 25mg / l A complete set of dosing devices are used with powdered activated carbon, including dry speculation, dissolution tank, metering pump and matching pipes and valves. Through the mixing, reaction, flocculation, precipitation, clarification, separation, adsorption, and filtration of clarifiers, valveless filters, and multi-media filters, some suspended solids, colloidal substances, organic substances, oils, alkalinity su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com