Heat exchange plate for plate heat exchanger

A technology of plate heat exchanger and heat exchange plate, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of many molds, difficult assembly and operation, etc., to improve heat transfer coefficient and reduce equipment Investment, the effect of improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

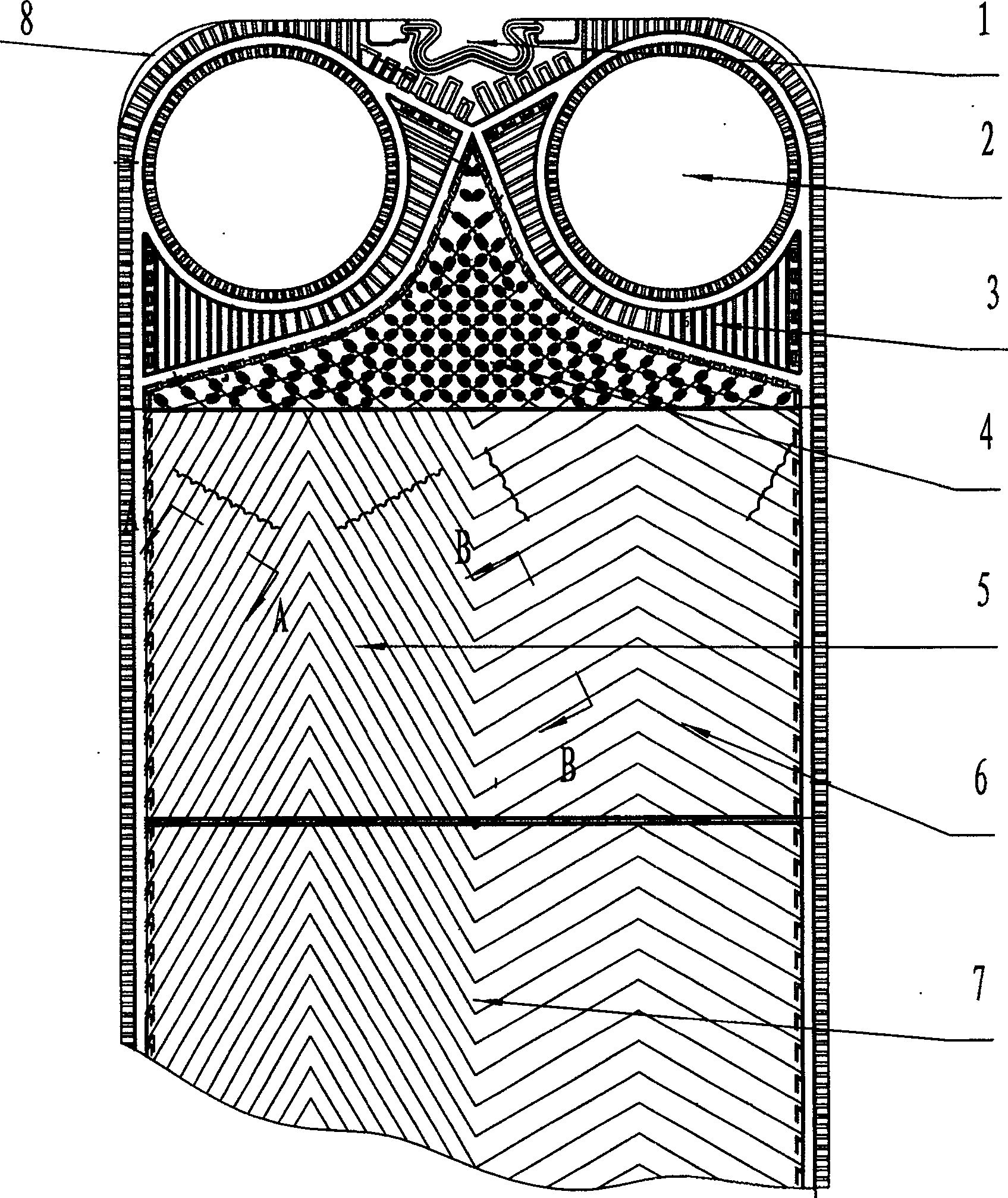

[0014] Embodiment 1, a heat exchange plate of a plate heat exchanger, made of pressed stainless steel plate, including positioning hole 1, medium inlet and outlet 2, inlet and outlet diversion area 3, diversion area 4, heat transfer area, its structure is: The plate corrugation in the heat transfer zone is divided into two sides by the center line of the plate, and the obtuse-angle corrugation 6 on one side is connected to the acute-angle corrugation 5 on the other side.

Embodiment 2

[0015] Embodiment 2, a heat exchange plate of a plate heat exchanger, made of pressed stainless steel plate, including positioning hole 1, medium inlet and outlet 2, inlet and outlet diversion area 3, diversion area 4, heat transfer area, its structure is: The plate corrugation in the heat transfer zone is divided into two sides by the center line of the plate, one side is a 120° obtuse angle corrugation 6 connected to the other side 60° acute angle corrugation 5, and a reinforcing rib 7 is added between the two corrugations.

Embodiment 3

[0016] Embodiment 3, a heat exchange plate of a plate heat exchanger, made of pressed stainless steel plate, including positioning hole 1, medium inlet and outlet 2, inlet and outlet diversion area 3, diversion area 4, and heat transfer area, its structure is: The plate corrugation in the heat transfer zone is divided into two sides by the center line of the plate, one side is a 120 ° obtuse angle corrugation 6 connected to the other side of the 60 ° acute angle corrugation 5, and a reinforcing rib 7 is added between the two corrugations; The diameter ratio of the corrugated runners on both sides of the heat plate is 1:2.2; the four corners of the heat exchange plate are provided with corner lock pieces 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com