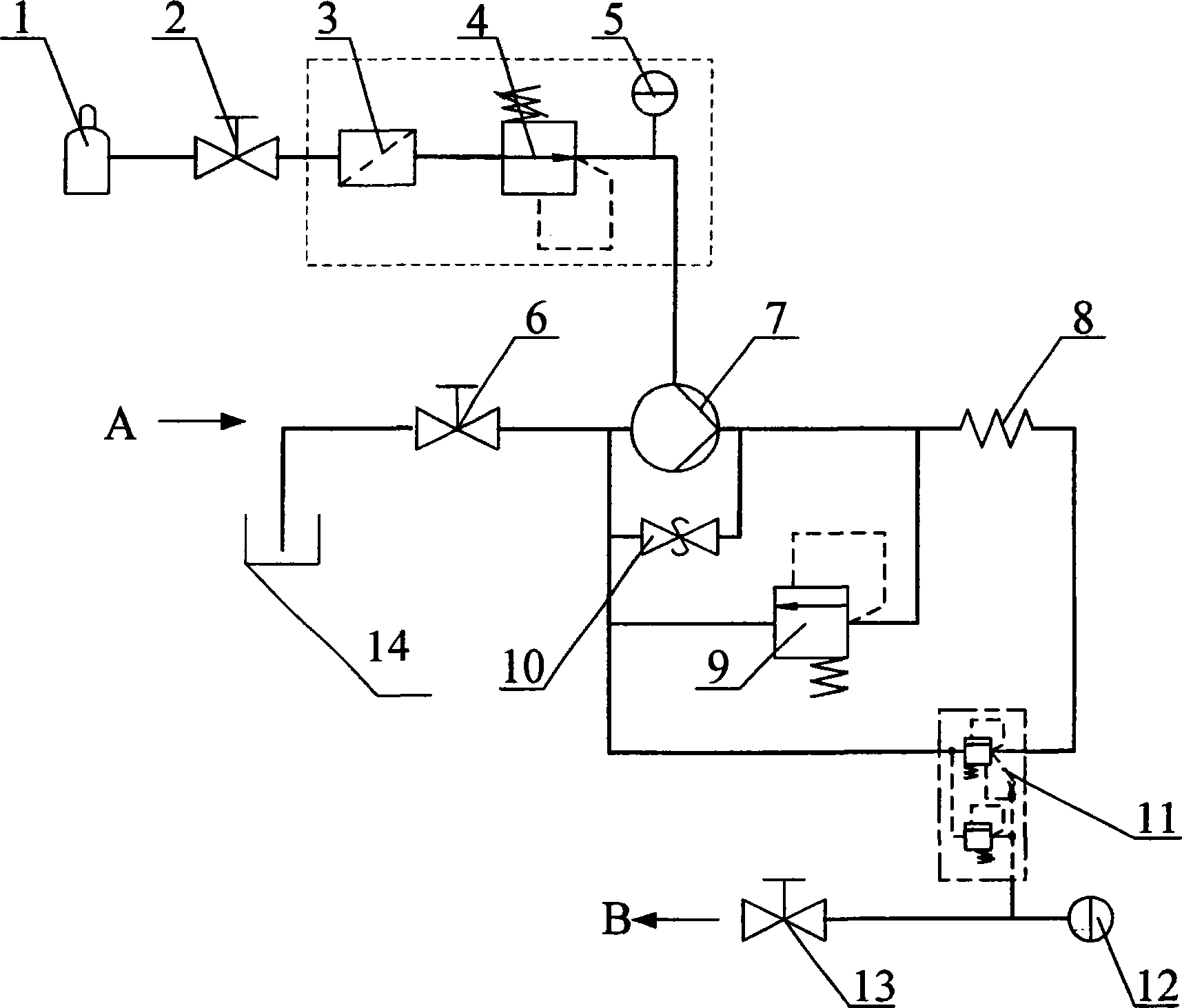

Test-bed support fuel supplying voltage-stabilizing system

A technology for fuel supply and test bench, which is applied in engine testing, machine/structural component testing, and measuring devices, etc., can solve the problems of short service life of electric fuel pumps, easy damage to built-in fuel pumps, and easy fires. Achieve the effect of compact structure, stable fuel pressure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Such as figure 1 Shown: Compressed air supply device 1 provides compressed air, enters the pneumatic pressure regulating valve 4 through the intake valve 2 through the filter 3, adjusts to a predetermined pressure value, and sends it to the pneumatic diaphragm pump 7, and the pressure gauge 5 shows the supply to the pneumatic pump 7 gas pressure. A fuel pressure stabilizing valve 9 is also provided on the outlet oil path of the pneumatic diaphragm pump 7, and is connected in parallel with the circuit formed by the hydraulic damping pipe 8 and the pressure relief port of the hydraulic pressure regulating valve 11. The external fuel is fed into the inlet of the pneumatic diaphragm pump 7 through the fuel inlet valve 6. Before the fuel output by the pneumatic diaphragm pump 7 enters the fuel damping pipe 8, if there is a peak value, a part of the fuel will flow back into the fuel tank through the fuel pressure stabilizing valve 9 to achieve a stable pressure. The other pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com