Electrochemical sensor for appraising ultraviolet shielding behaviour of nanometer oxide powder

A technology of nano-oxide and powder materials, which is applied in the field of nano-sensors, can solve the problems of cumbersome operation, sensor description, and large sample consumption, and achieve the effects of low process requirements, rapid evaluation, and low analysis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

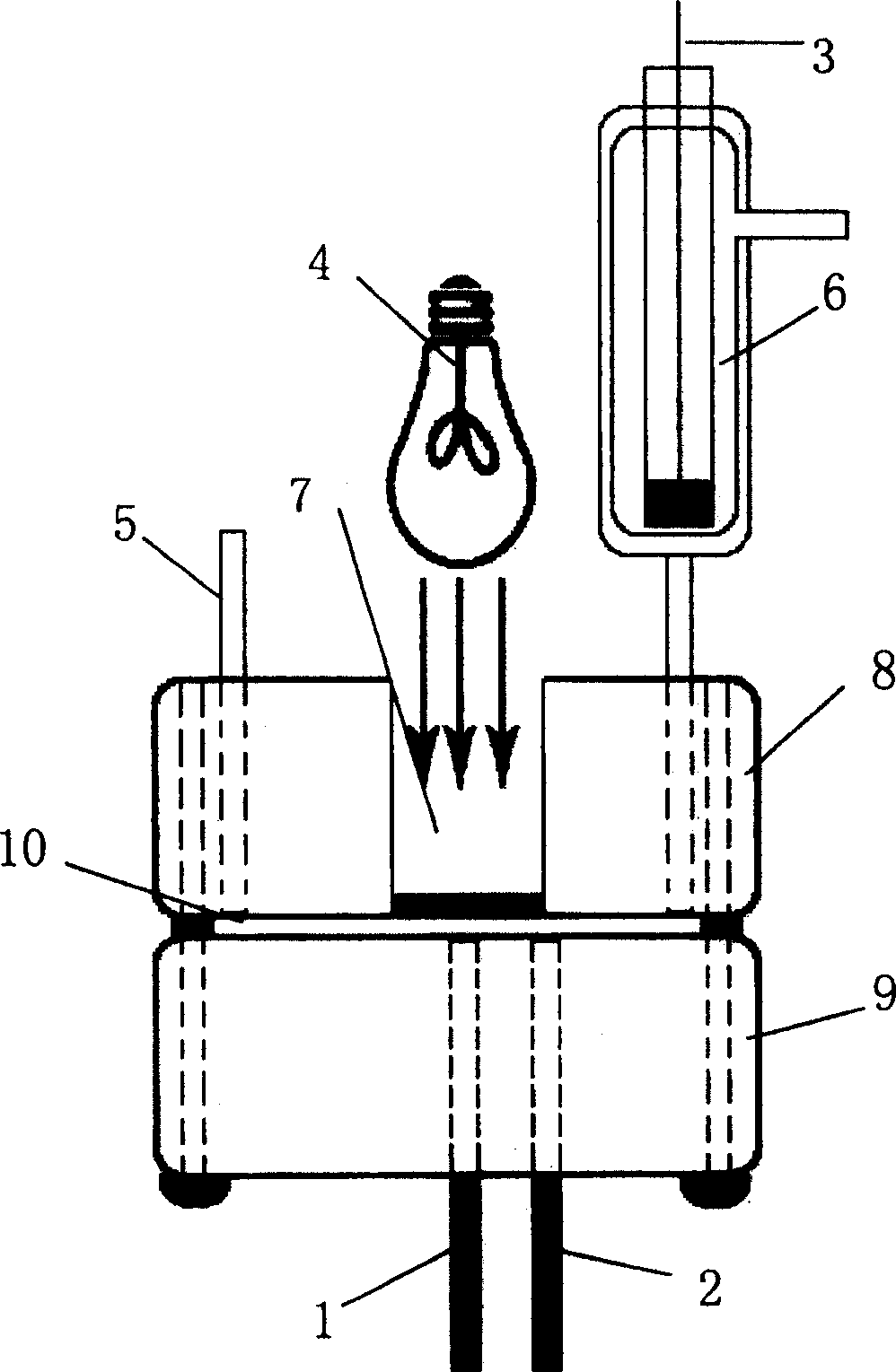

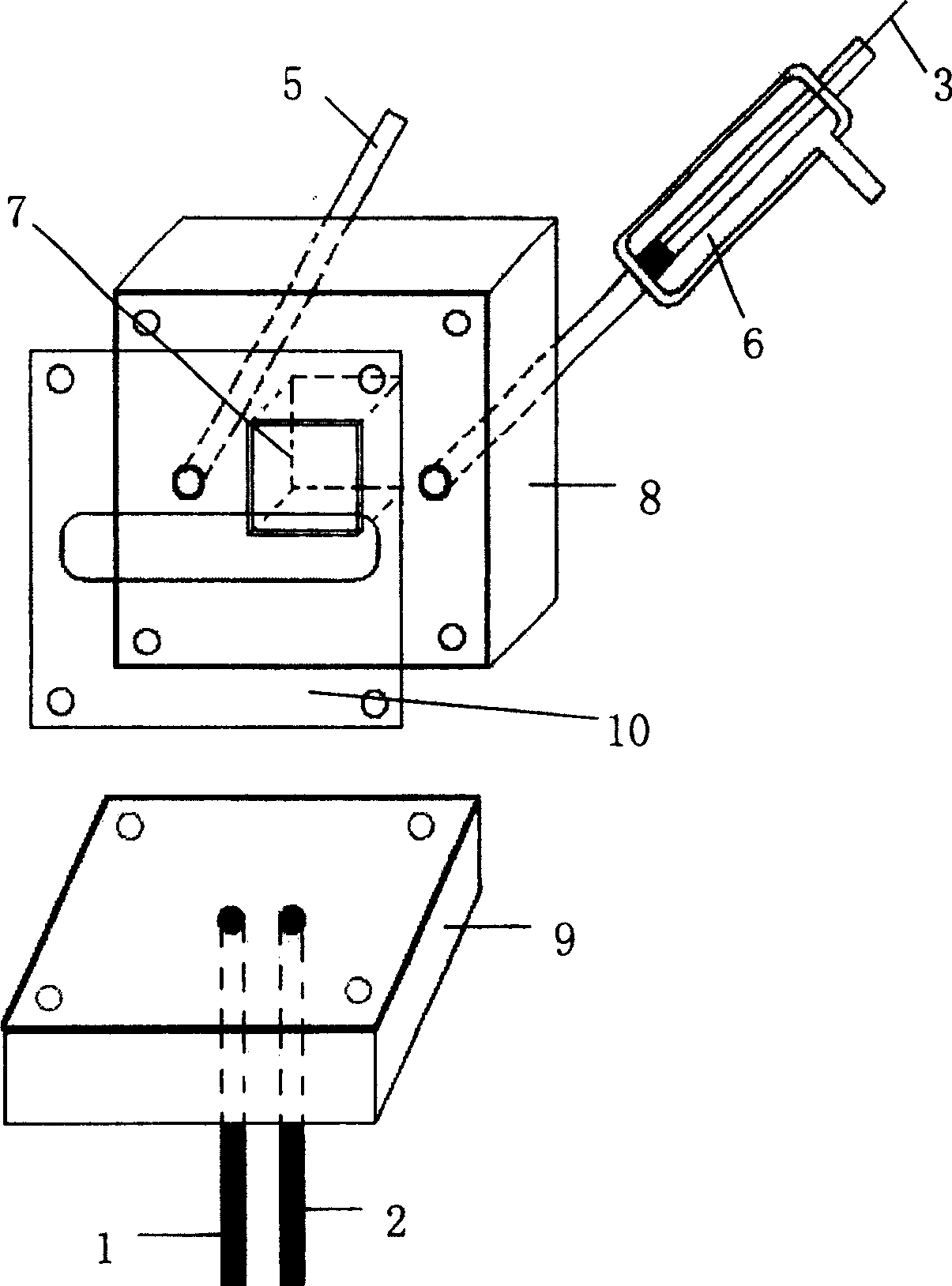

[0017] The working process of the electrochemical sensor for evaluating the ultraviolet shielding performance of nano-oxide powder materials provided by the present invention is discussed in detail below in conjunction with the accompanying drawings:

[0018] The chemical sensor consists of a working electrode 1, a counter electrode 2, a reference electrode 3, an ultraviolet lamp 4, an inlet tube 5, an outlet tube 6, a quartz window 7, an upper cover plate 8, a lower cover plate 9 and a polytetrafluoroethylene film 10, Wherein the inlet tube 5 and the outlet tube 6 are respectively placed on both sides of the upper cover plate 8, the reference electrode is placed inside the outlet tube 6, the center of the upper cover plate 8 is inlaid with a quartz window 7, and the ultraviolet lamp 4 is placed between the quartz window 7 Inside, the polytetrafluoroethylene membrane 10 is placed between the upper cover plate 8 and the lower cover plate 9, and there is a strip-shaped gap in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com