Device and method for estimating spin forming limits of high-strength steel and tailor-welded blank

A technology of spin forming and evaluation device, applied in the direction of testing the ductility of materials, etc., can solve the problems of large limit thinning rate, large influence, rough method, etc., and achieve the effect of simple structure, data continuity, and reasonable evaluation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

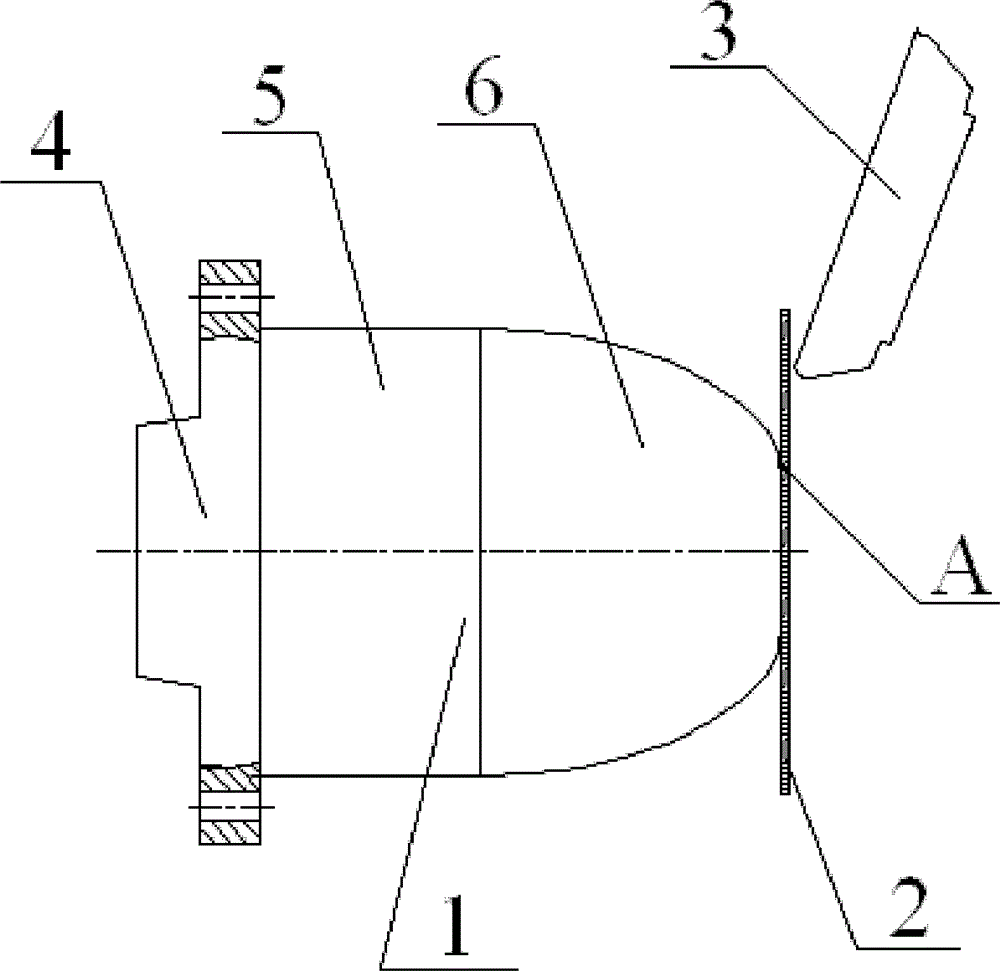

[0042] figure 1 The structure of the spin forming limit evaluation device for high-strength steel and tailor welded blanks in this embodiment is shown. Such as figure 1 As shown, the evaluation device includes a spinning wheel 3 and a mandrel 1 . The mandrel 1 includes an assembly part 4 located at one end of the mandrel 1 , a shaft body part 5 located at the middle of the mandrel 1 , and a molding part 6 located at the other end of the mandrel 1 . Among them, the assembly part 4 is used for the connection between the mandrel 1 and the equipment; the shaft part 5 is cylindrical, which provides space for the elongation of the blank, and does not play a role in forming itself; the forming part 6 is ellipsoidal, The outer contour of the tangential plane of the forming part 6 along its axial direction includes a straight line segment with a length of 120mm, and two elliptic curve segments respectively connected to the two ends of the straight line segment. , the curve equation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com