Drilling tool with alternating cutting plates therefor

A technology for drilling tools and blades, applied in drilling tool accessories, cutting blades, manufacturing tools, etc., can solve problems such as insufficient removal of replaceable blade breakage, and achieve the effect of reducing chip jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

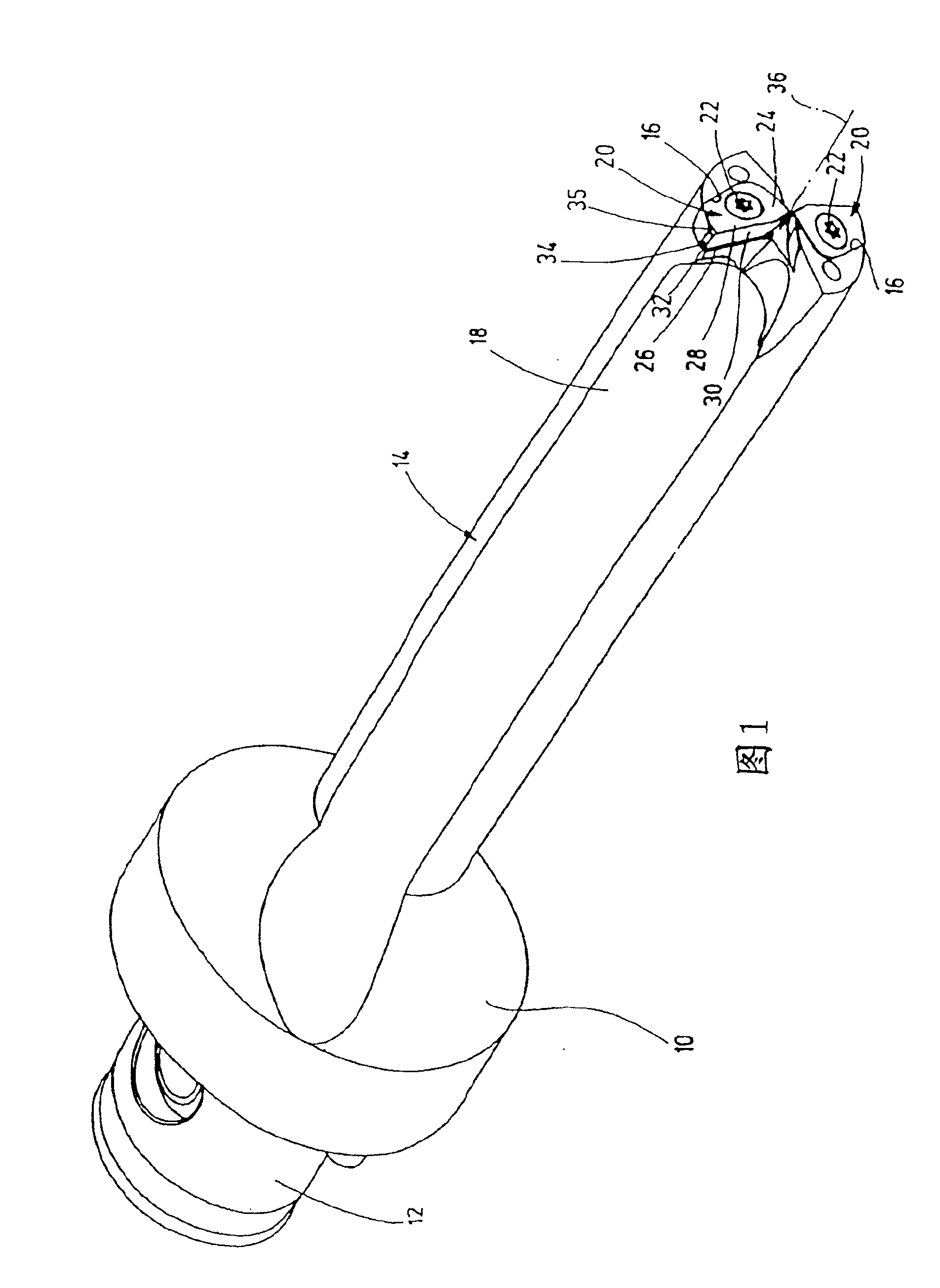

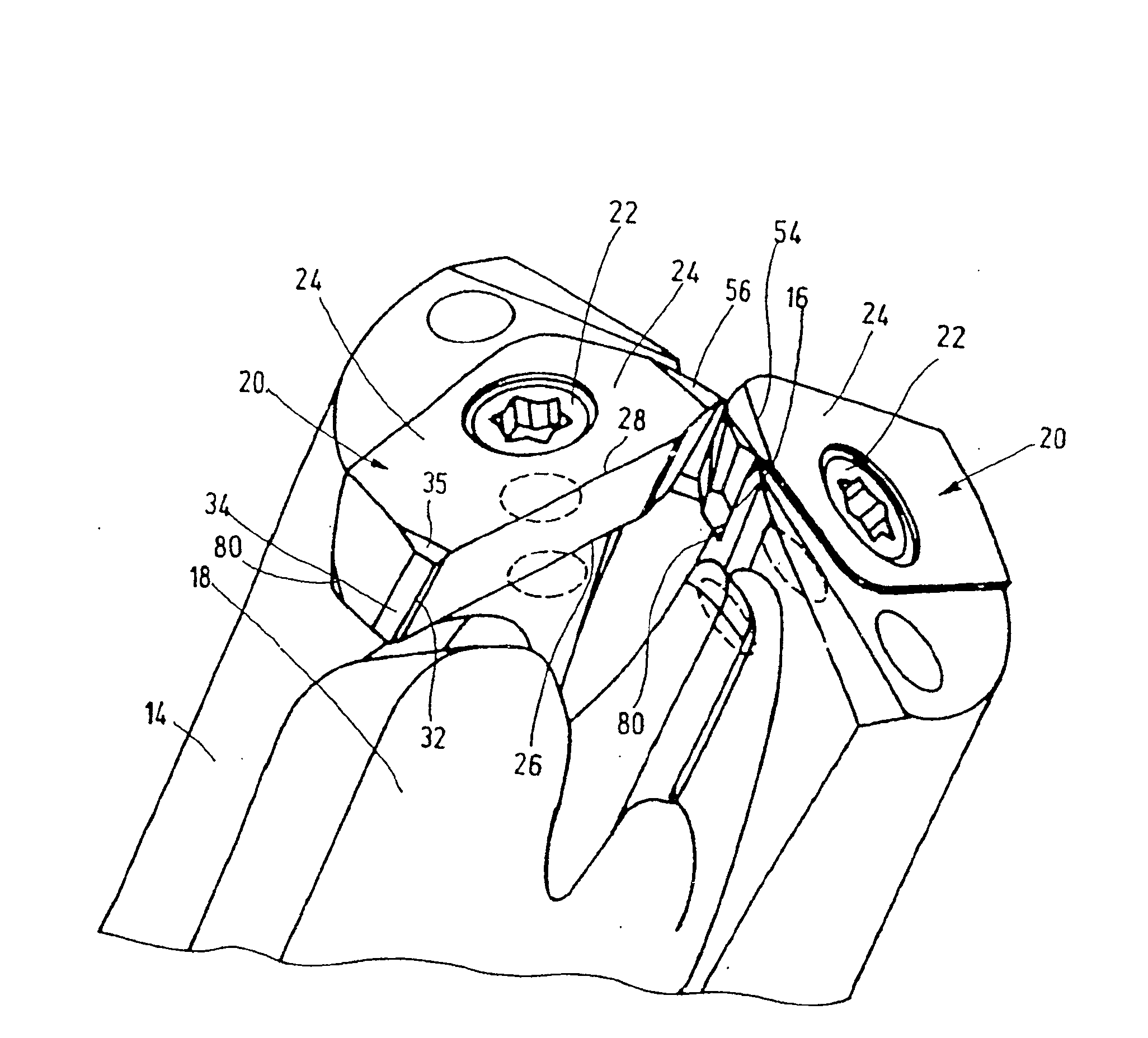

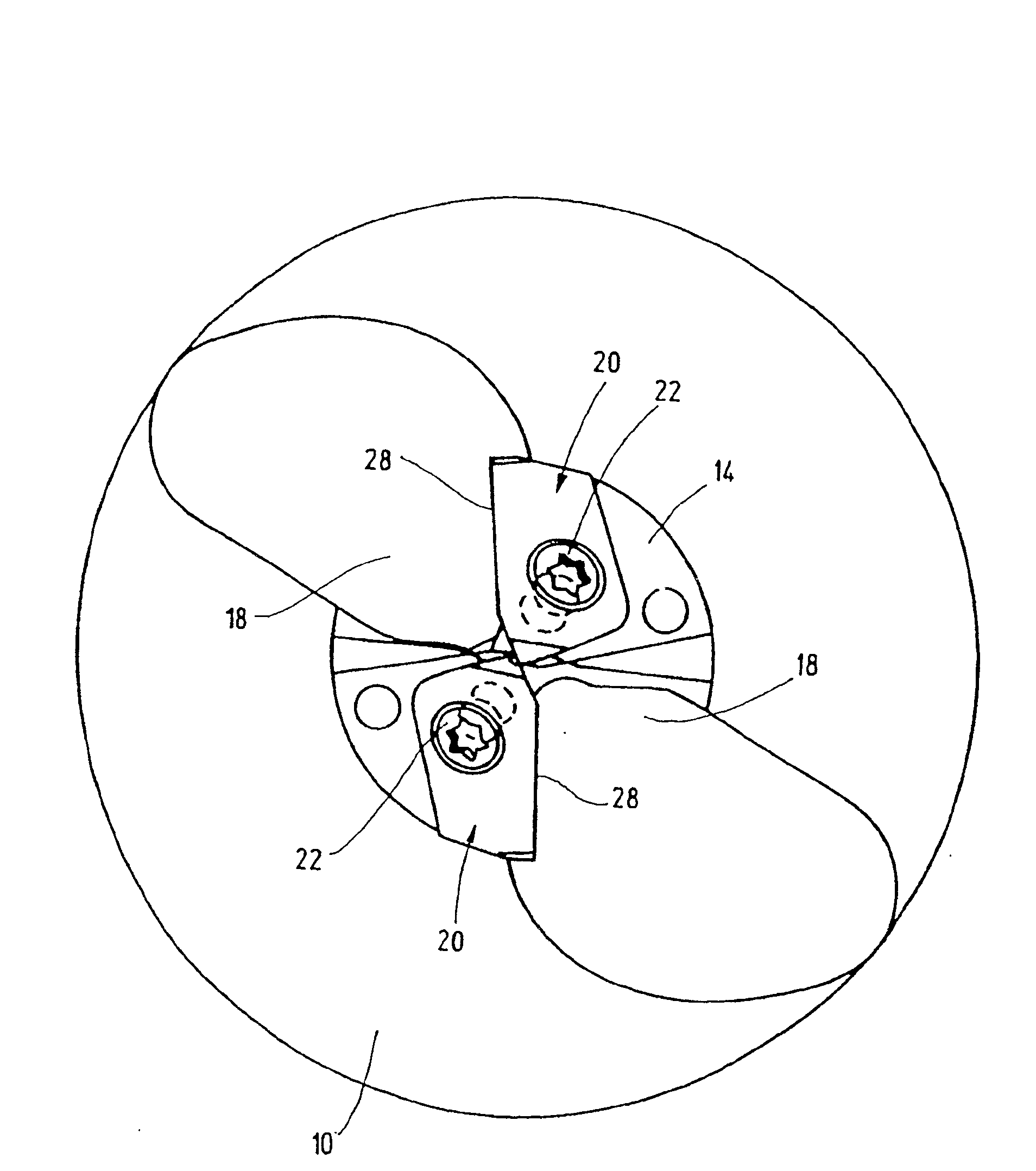

[0034] The drilling tool shown in the drawings consists of a double-edged solid drill. These drilling tools are suitable for machine tools and for this purpose have a coupling shank 12 for connection to a not shown machine tool spindle, which is defined by a coupling flange 10 for flat positioning. Furthermore, a longitudinally extending base body 14 is connected via a connecting flange 10 , which is provided on the end face with two insert seats 16 , from which chip flutes 18 extend along the length of the base body 14 . Two replaceable blades 20 of the same structure are arranged in the blade seat 16 and fixed on the base body 14 by fixing bolts 22 .

[0035] The insert 20 arranged upright according to FIGS. 1 to 5 has a cutting face 24 and a bearing face 26 facing away from this cutting face, which are aligned plane-parallel to one another. On the chip flute side, the cutting face 24 is bounded by a main edge 28 and a chip surface 30 adjoining the main edge and opening int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com