Coal and gas burning mixed ceramic sintering process and push bat kiln

A coal-fired and gas-fired technology, which is applied in the ceramic sintering process and the pusher kiln field, can solve the problems of poor surface gloss of ceramic products, difficult control of product quality, and inability to fire high-temperature ceramics, etc., to achieve good glaze finish and high product quality. The effect of improving and improving product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

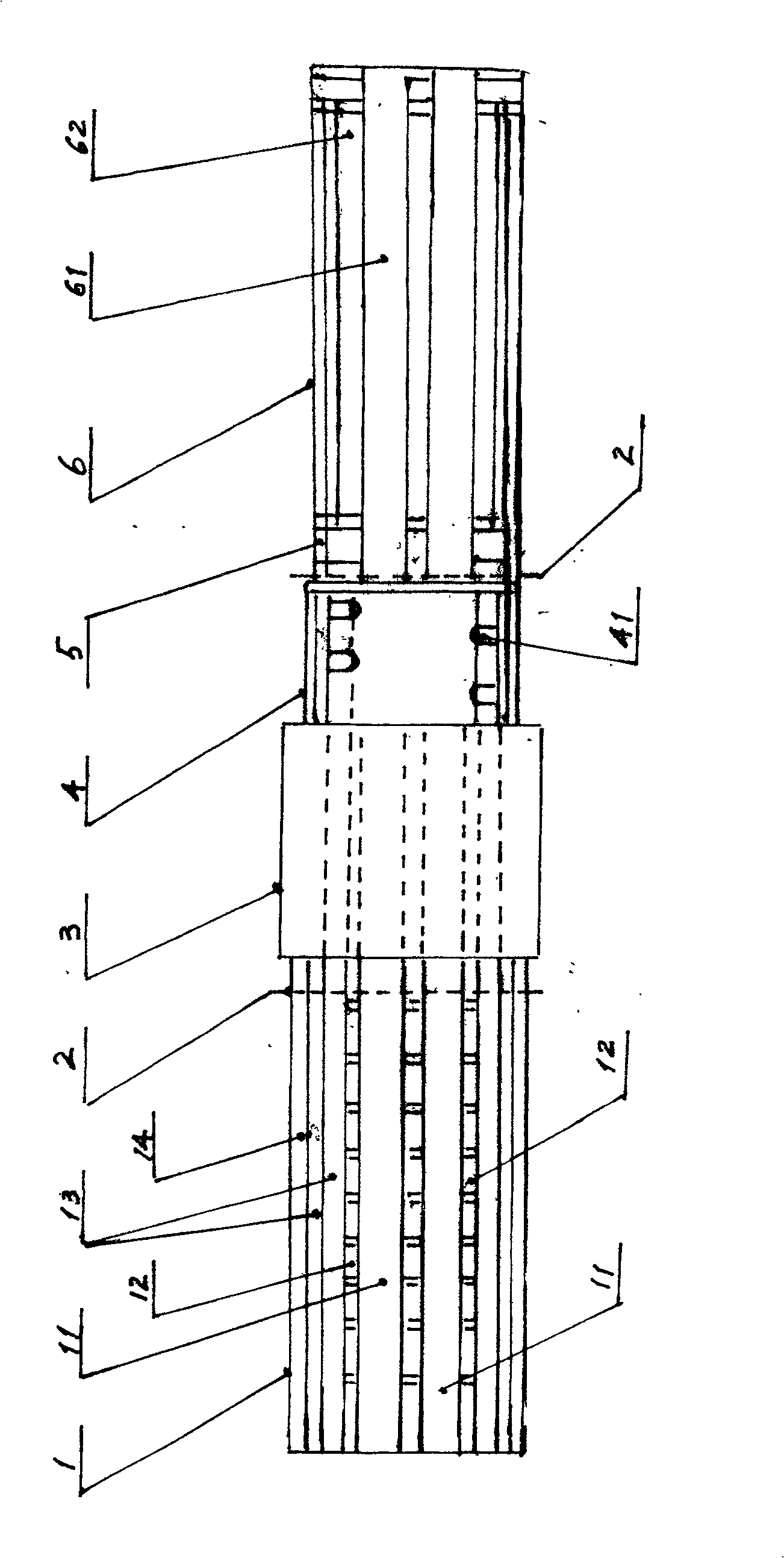

[0011] Referring to the accompanying drawings, it is a ceramic sintering process of coal and gas co-firing, which obtains finished products by preheating, sintering and cooling the green body. It is characterized in that: coal preheating and gas sintering are used in the ceramic sintering The two combustion methods, that is, the coal-fired flame-fired combustion method is used for preheating and the gas-fired direct-flame combustion method is used for sintering. The gas is liquefied gas, natural gas or coal gas; Combustion chamber for naked burning;

[0012] When producing low-temperature ceramic products, the combustion temperature of coal is 1100°C, while the combustion temperature of gas is less than 1300°C;

[0013] When producing high-temperature ceramic products, the combustion temperature of coal is 1250°C, and the combustion temperature of gas is less than or equal to 1500°C.

[0014] A ceramic pusher kiln for co-firing coal and gas, which includes a preheating sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com