Liquid detergent and cleaning agent composition

A technology of liquid detergent and composition, applied in detergent composition, coating detergent composition, detergent compounding agent, etc., can solve the problems of prolonged dissolution time and more active oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

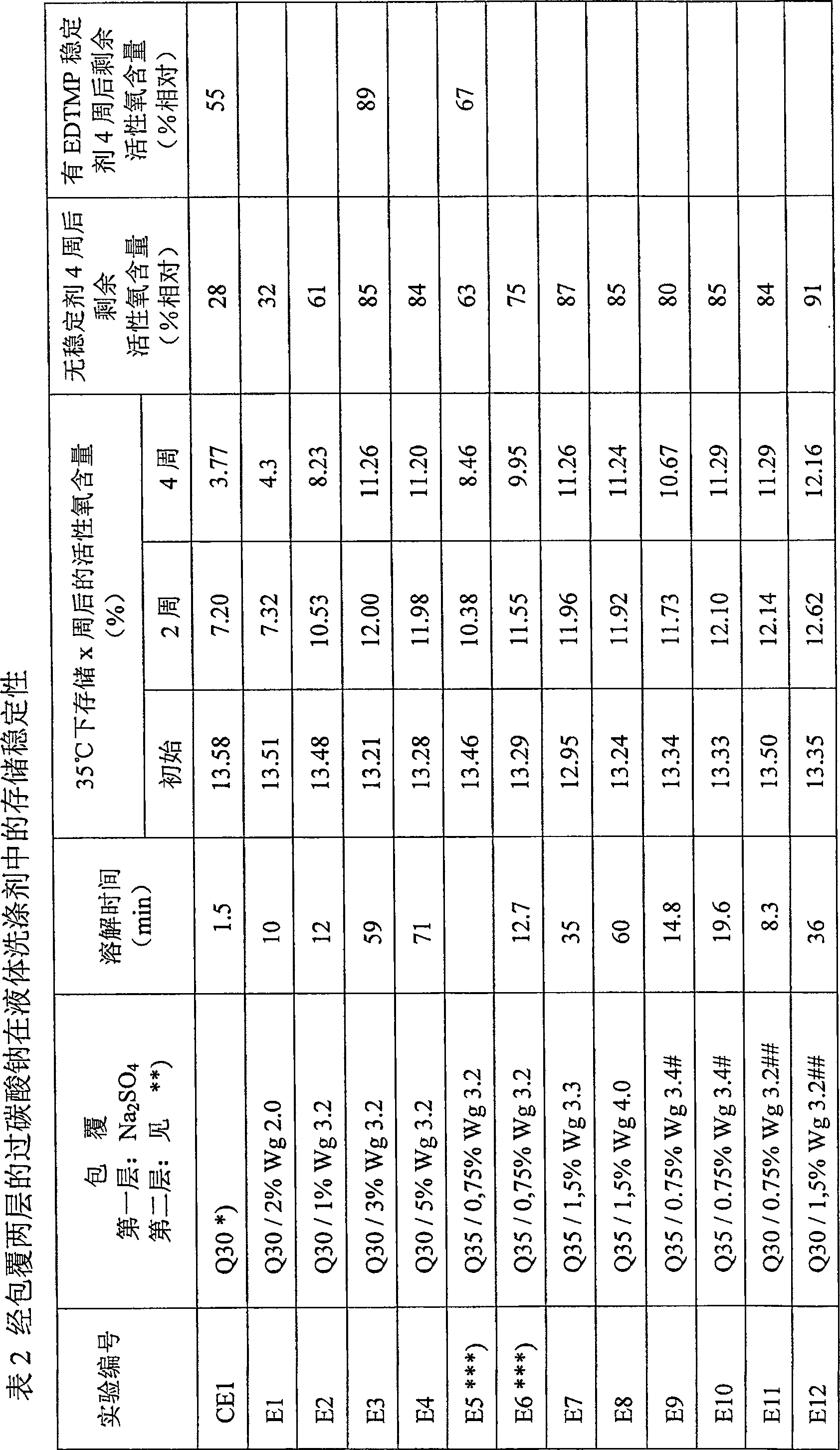

[0067] a) Preparation of coated bleach

[0068] Two-layer coated sodium percarbonate is prepared by coating sodium percarbonate in a fluidized bed, the first layer mainly containing sodium sulfate and the second layer mainly containing sodium silicate. Details of the preparation and modifications can be found in DE 102 61 161.0.

[0069] In these examples, commercially available sodium percarbonate coated with 6% by weight of sodium sulfate was used as starting material, i.e. Q30 and Q35 from Degussa Company, the difference is only in particle size distribution, Q35 is coarser than Q30 (Q30: D 50 =0.55mm, Q35: D 50 = 0.70mm).

[0070] Coat Q30 or Q35 in a fluidized bed coating device using water glass solution. Spraying was carried out at a fluidized bed temperature of about 60°C. Air was used as fluidized bed gas at an inlet temperature of about 100°C. After spraying, the temperature of the incoming air is slightly lowered, and post-drying is carried out at a fluidized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com