Fluororesin-containing electrodeposition coating material

A technology of electrodeposition and coating, applied in the field of electrodeposition coatings, can solve the problems of insufficient storage stability of coatings, low compatibility between fluororesin composition and curing agent, etc., and achieve the effect of sufficient storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

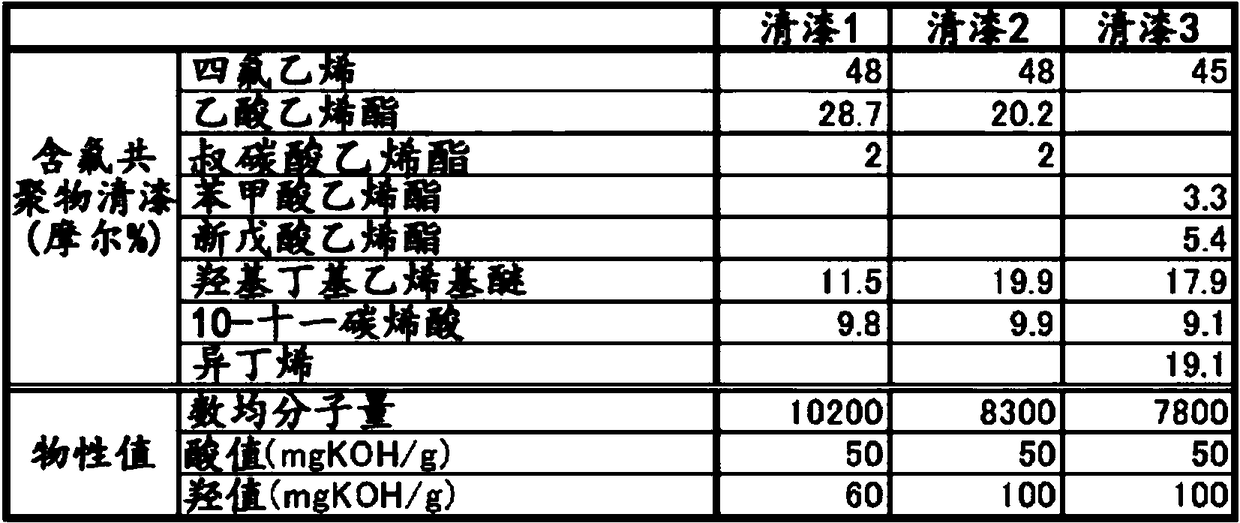

Method used

Image

Examples

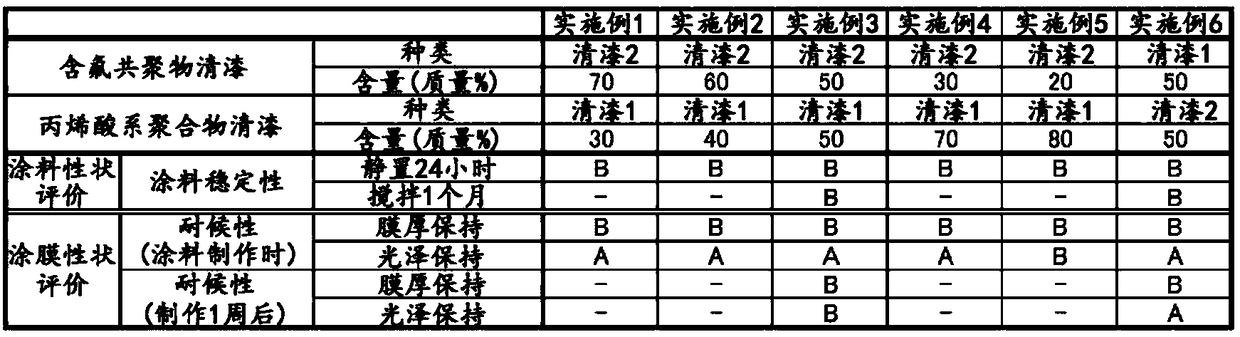

Embodiment 1

[0117] The fluorine-containing copolymer varnish 2 and the acrylic polymer varnish 1 were mixed so that the solid content mass ratio would be 70:30. 120 parts by mass of the obtained mixed varnish (60 parts by mass as solid content), 4.5 parts by mass of triethylamine (0.8 equivalent in acid value with respect to the mixed varnish), and 100% fully etherified melamine resin (NIKALAC MX-45, triethylamine) were prepared. It was mixed with 40 parts by mass of Chemical Industry Co., Ltd.), and 835.5 parts by mass of deionized water was added with stirring to prepare the electrodeposition coating composition of Example 1.

Embodiment 2~6、 comparative example 1~6

[0119] The same substances and Method The electrodeposition paint compositions of Examples 2 to 6 and Comparative Examples 1 to 6 were prepared.

[0120] Using the obtained electrodeposition paint compositions of the respective Examples and Comparative Examples, evaluations of paint properties shown below were performed.

[0121] [Coating stability test (standing for 24 hours)]

[0122] After the above-mentioned coating composition was prepared, the appearance of the coating composition after standing for 24 hours was visually evaluated according to the following criteria, and evaluation B was evaluated as acceptable, and evaluations C and D were evaluated as unacceptable. The results are shown in Table 3 and Table 4.

[0123] (Evaluation Criteria)

[0124] B: No abnormality confirmed

[0125] C: Sedimentation of a part of the resin is observed

[0126] D: The resin settles completely

[0127] [Coating stability test (stirring for 1 month)]

[0128] After the above coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com