Water-soluble organic silicon defoamer composition and water-based paint containing same

A technology of silicone defoamer and water-based paint, applied in the direction of paint, coating, foam dispersion/prevention, etc. containing biocide, it can solve the problems of limited use, inability to dissolve and reduce uniformly, and achieve full defoaming Characteristics, the effect of sufficient storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 and comparative example 1~2

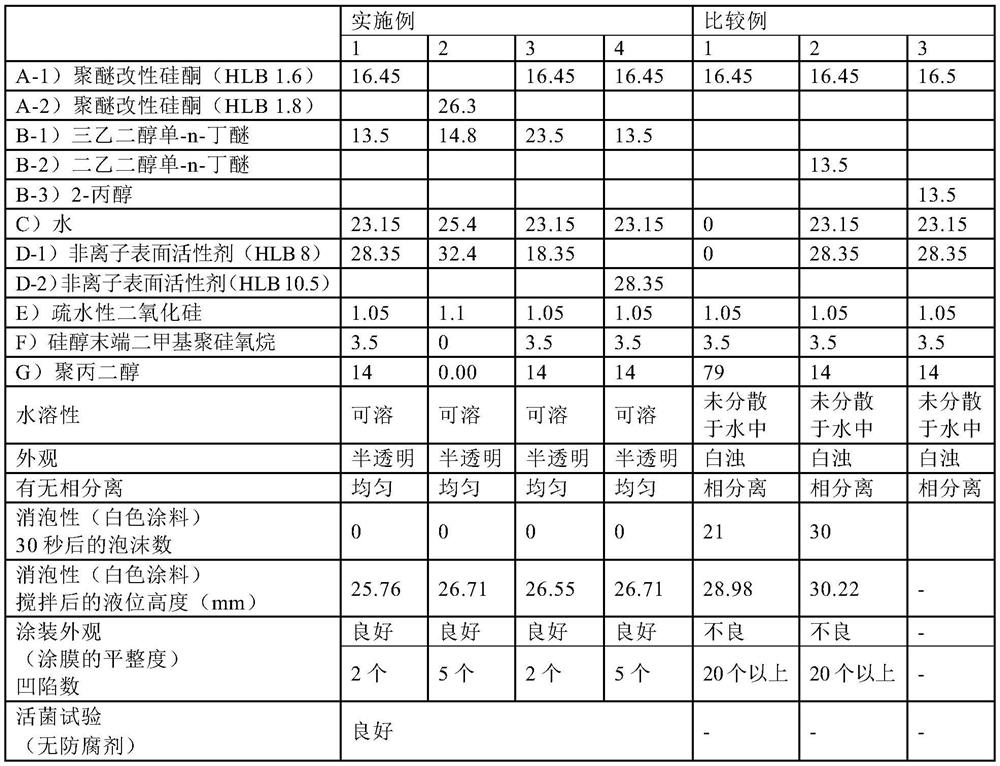

[0114] Stir and mix the above components with mechanical force (stirrer) to make the concentration reach the concentration (mass fraction) described in Table 1, adjust the water-soluble silicone defoamer, and after standing for 24 hours and 1 week, use the above method to judge its composition. The appearance and the presence or absence of phase separation are recorded in Table 1.

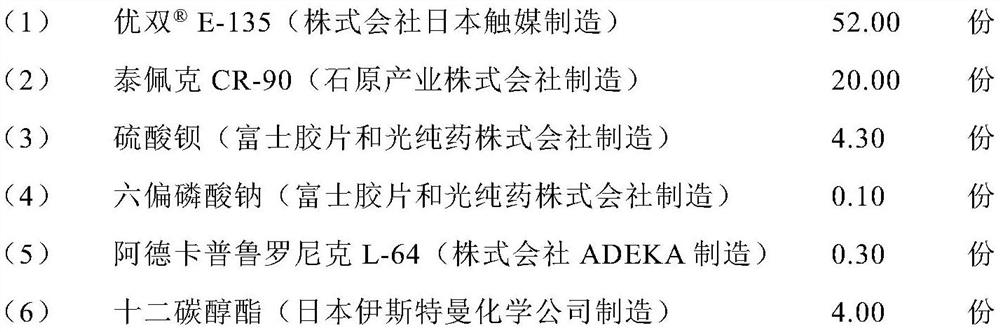

[0115] In addition, 0.4 part by mass (%) was added to the acrylic emulsion paint (based on EUDO (registered trademark) E-135 Co., Ltd. Nippon Shokubai Co., Ltd.), and the mixture was uniformly stirred by mechanical force (mixer), and its defoaming and other properties were evaluated by the above method. , and are shown in the table below.

[0116] [Table 2]

[0117]

Embodiment 5

[0121] The component B-1) of "Example 1" described in the above table was replaced with the component (B) of the present invention, that is, component B-14), and in the same manner as in Example 1, it was mechanically (stirred) Stir and mix evenly, adjust the water-soluble silicone defoamer, and after standing for 24 hours, use the above method to determine whether there is phase separation and record it. The results show that after using B-14) triethylene glycol butyl methyl ether, the composition can be uniformly dispersed and the composition can be dissolved in water.

[0122]

[0123] The water-soluble silicone antifoaming agents of the examples can be dissolved in water, so they are excellent in handling operability and uniform dispersibility, and if they are simply mixed with a mixer, a uniform and transparent silicone composition will be formed. , phase separation and other phenomena will not occur after 1 week. Furthermore, the composition not only obtains a uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com