Air compressor

An air compressor and compressed air technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems such as large impact on equipment service life, high motor starting current, and inaccurate pressure control. The effect of stable and reliable operation of the equipment, reduction of starting current and accurate pressure control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 is the implementation of using an electronically controlled unloading valve:

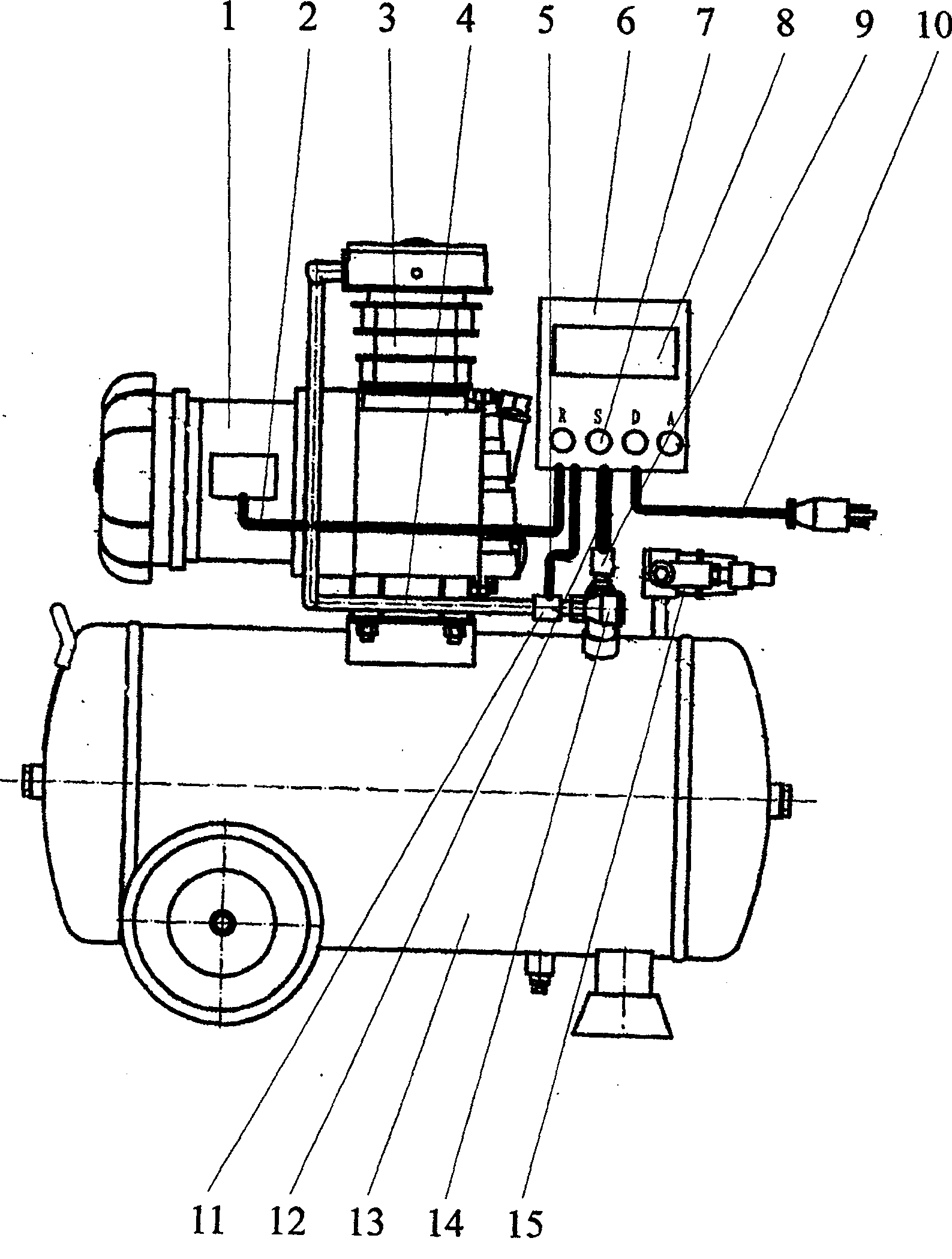

[0019] The motor (1) and the air compressor (3) adopt integral machines, which are fixed on the air storage tank (13), and the compressed air outlet pipe (4) of the air compressor is connected to the inlet of the unloading valve (11), and the unloading valve (11) ) is connected to the gas storage tank (13) via the tee pipe (14); the other port of the tee pipe (14) is connected to the pressure sensor (9), and the pressure sensor signal control circuit (12) is connected to the controller (6), The controller (6) is provided with a power cord and a power plug (10); the motor (1) is connected by the motor power cord (2) and the controller (6); the unloading valve signal control circuit (5) of the unloading valve (11) ) is connected to the controller (6); the controller (6) is arranged on the top of one end of the gas storage tank (13); the controller (6) is a single-chip microelectron...

Embodiment 2

[0020] Embodiment 2 is the implementation of using automatic unloading valve:

[0021] Since the present embodiment adopts an automatic unloading valve, the unloading valve signal control circuit (5) in the above-mentioned embodiment 1 is omitted, and the control circuit of the controller (6) can also be simplified a little, and the others are the same as in the first embodiment.

Embodiment 3

[0022] Embodiment 3: on the basis of embodiments 1 and 2, a frequency conversion circuit and a frequency conversion control circuit are added to the controller (6). According to the load of the air compressor, controlling the speed of the motor will greatly improve the performance indicators of the air compressor.

[0023] The prototypes of the above-mentioned embodiments 1, 2, and 3 can not only accurately control the output pressure, realize reliable control of the output pressure within the set upper limit pressure and lower limit pressure range, but also can display the current output pressure in numbers, which is clear and intuitive . The structure and production process are simple, the reliability is high, and the production cost is low. It can be widely used in industrial and agricultural production, national defense, scientific research and other fields.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com