Heat pipe device for electronic refrigerator and making method thereof

A technology for electronic refrigerators and heat pipe devices, which is applied to the operation mode of machines, machines using electric/magnetic effects, refrigerators, etc., can solve the problem of uneven wall thickness of the cavity, unsatisfactory heat transfer efficiency, and unsatisfactory users. and other problems, to achieve the effect of good heat exchange efficiency, convenient and sufficient condensation, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

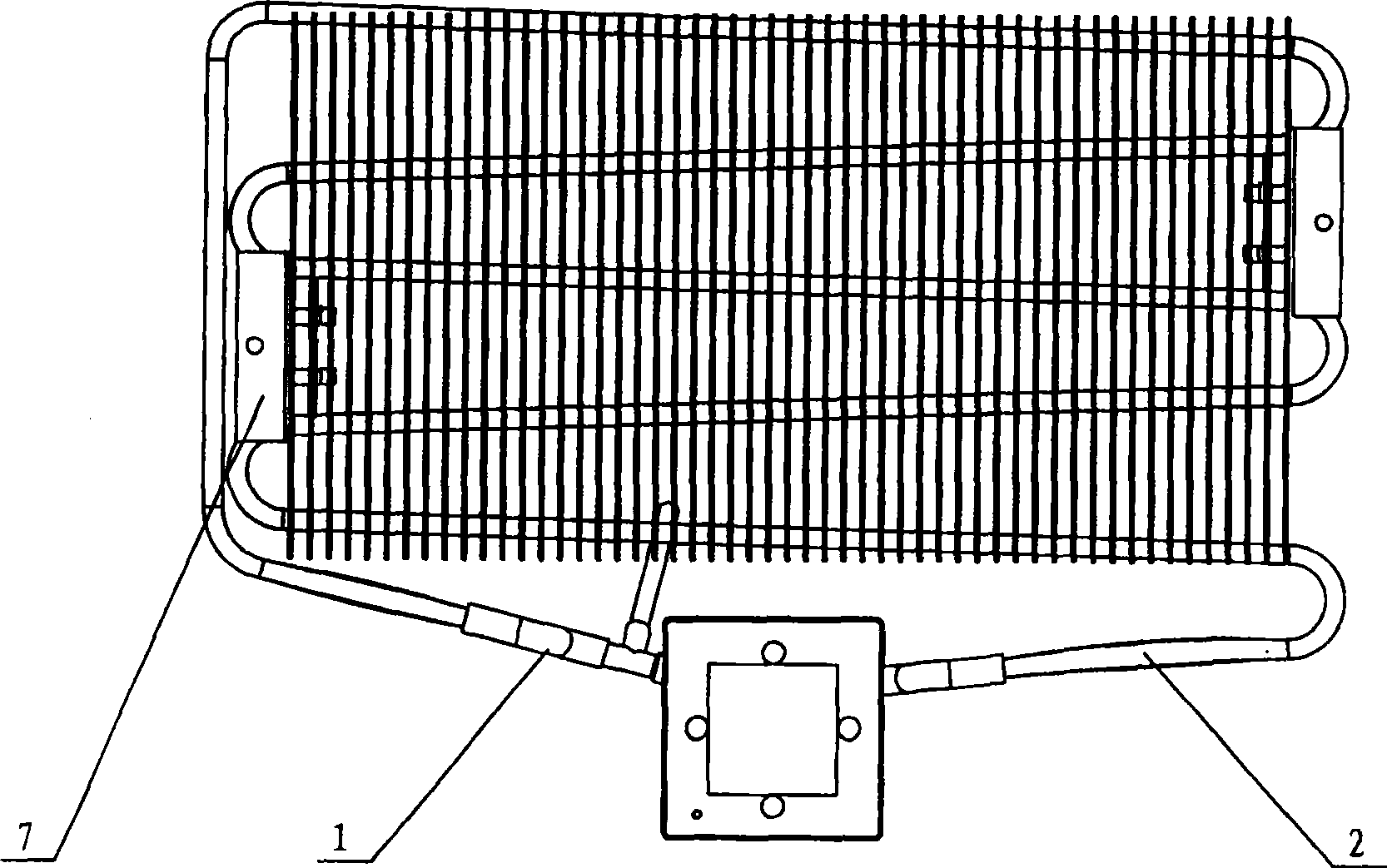

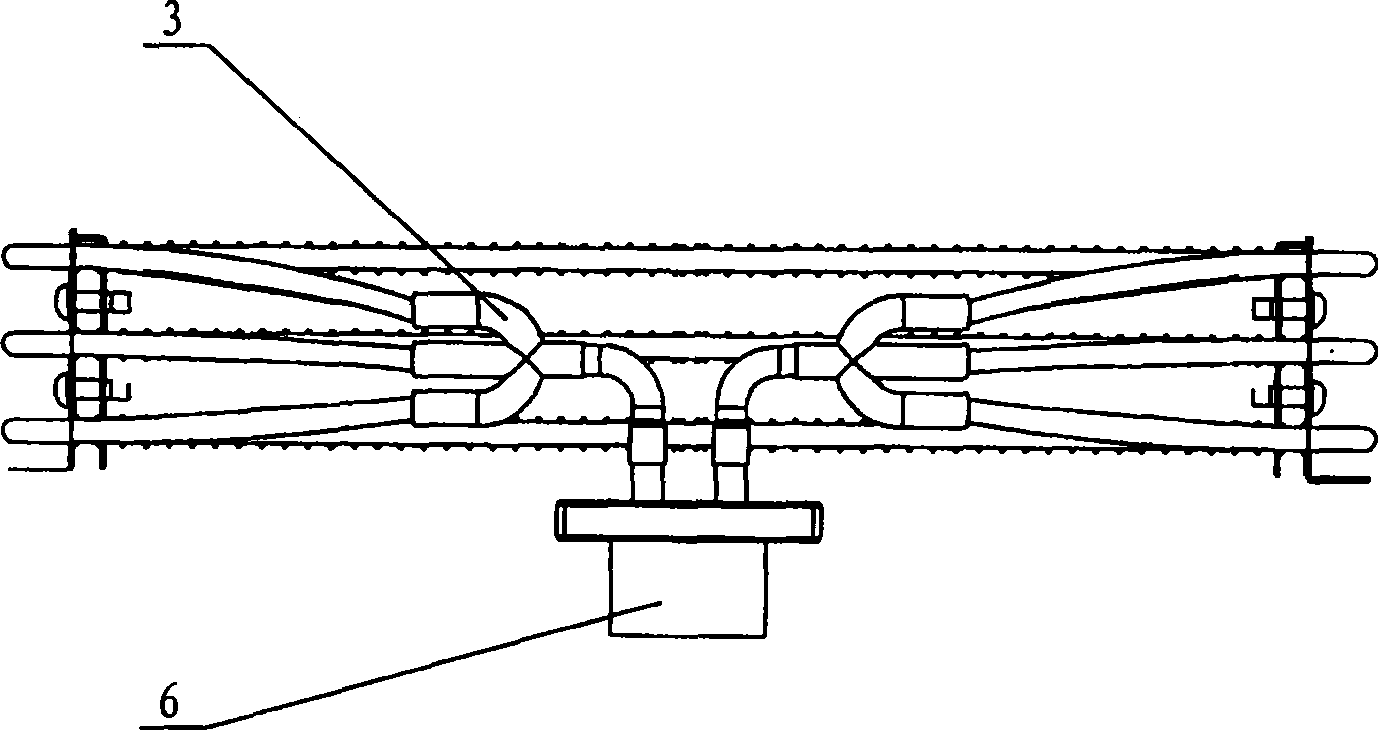

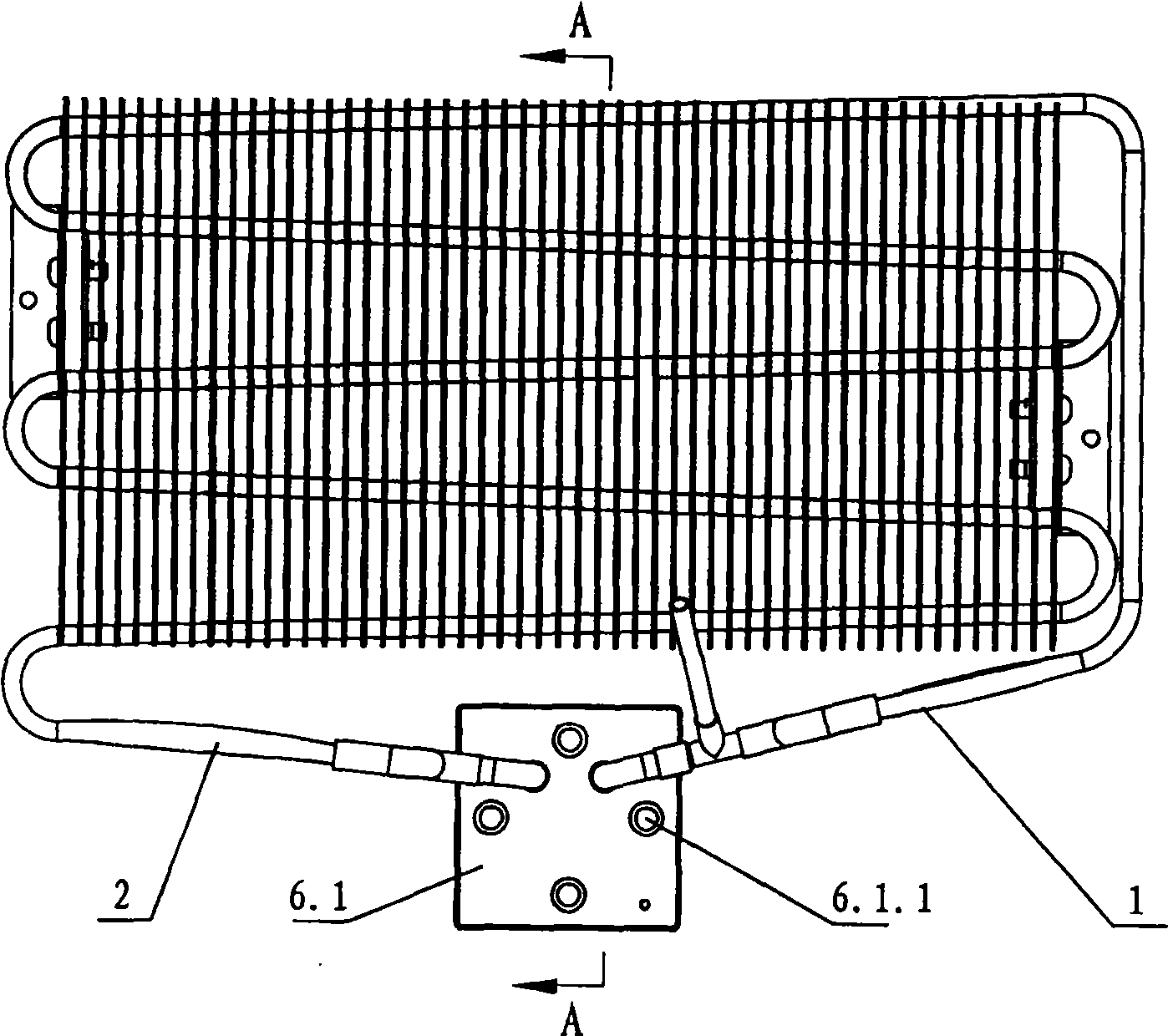

[0028] see Figure 1-Figure 6 , the heat pipe device of the electronic refrigerator includes a heat pipe arranged at the hot end of the refrigeration semiconductor, and fins are arranged on the heat pipe, and the heat pipe includes an evaporation pipe 1 for evaporating the refrigerant and a condensation pipe 2 for condensing the refrigerant, and the heat pipe passes through A prefabricated liquid storage chamber is connected to the hot end of the refrigeration semiconductor. The liquid storage chamber includes two left and right columnar chambers. The evaporation pipe 1 and the condensation pipe 2 are respectively connected to the upper parts of the two chambers. The two chambers pass through The communication pipe 5 communicates with each other, and the communication pipe 5 is located at the middle and lower parts of the two chambers, and the diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com