Hydraulic turbine drum valve electrohydraulic synchronous control system

A technology of synchronous control and water turbine, applied in the direction of hydroelectric power generation, mechanical equipment, engine components, etc., can solve problems such as application limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below through specific embodiments and with reference to the accompanying drawings.

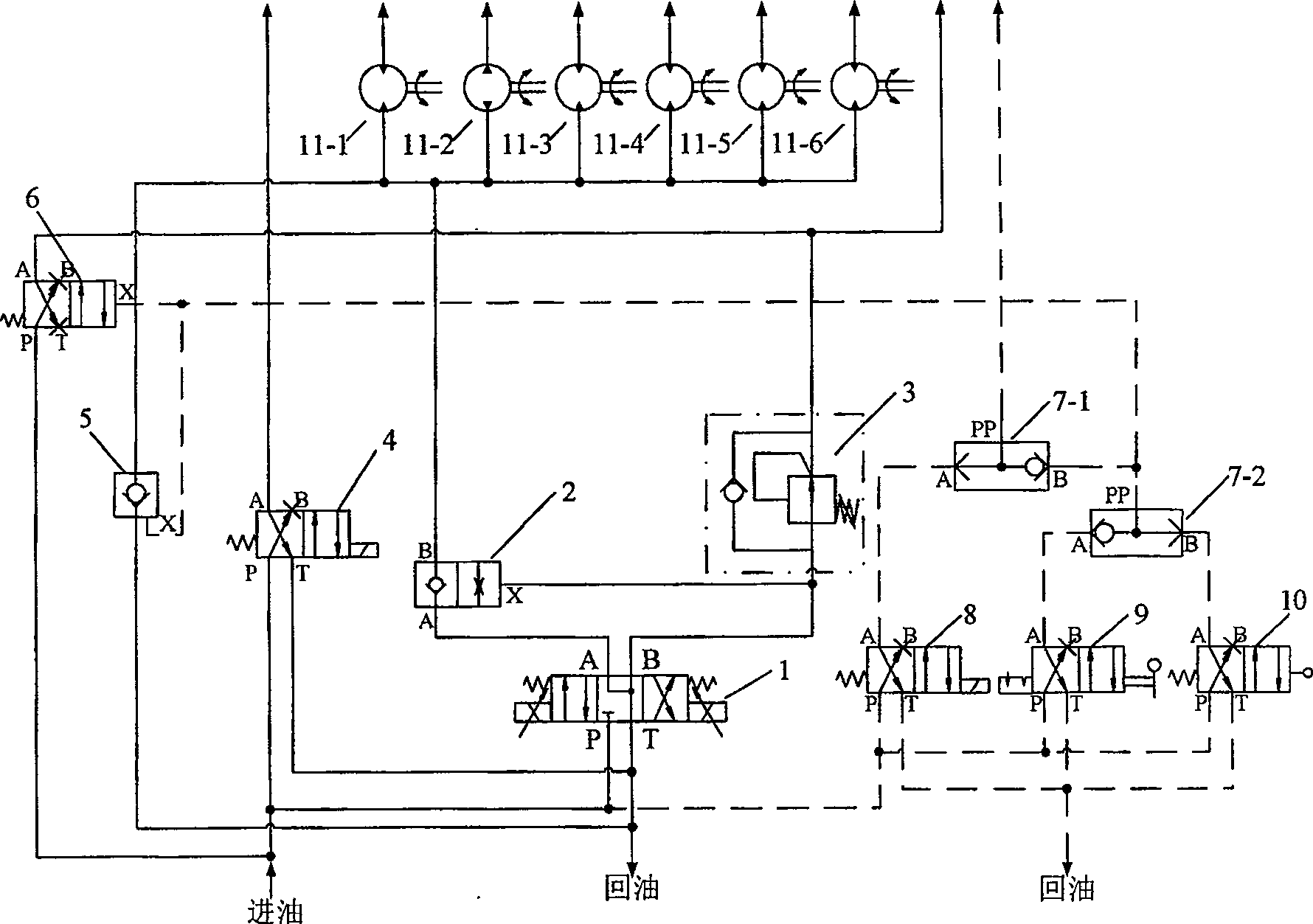

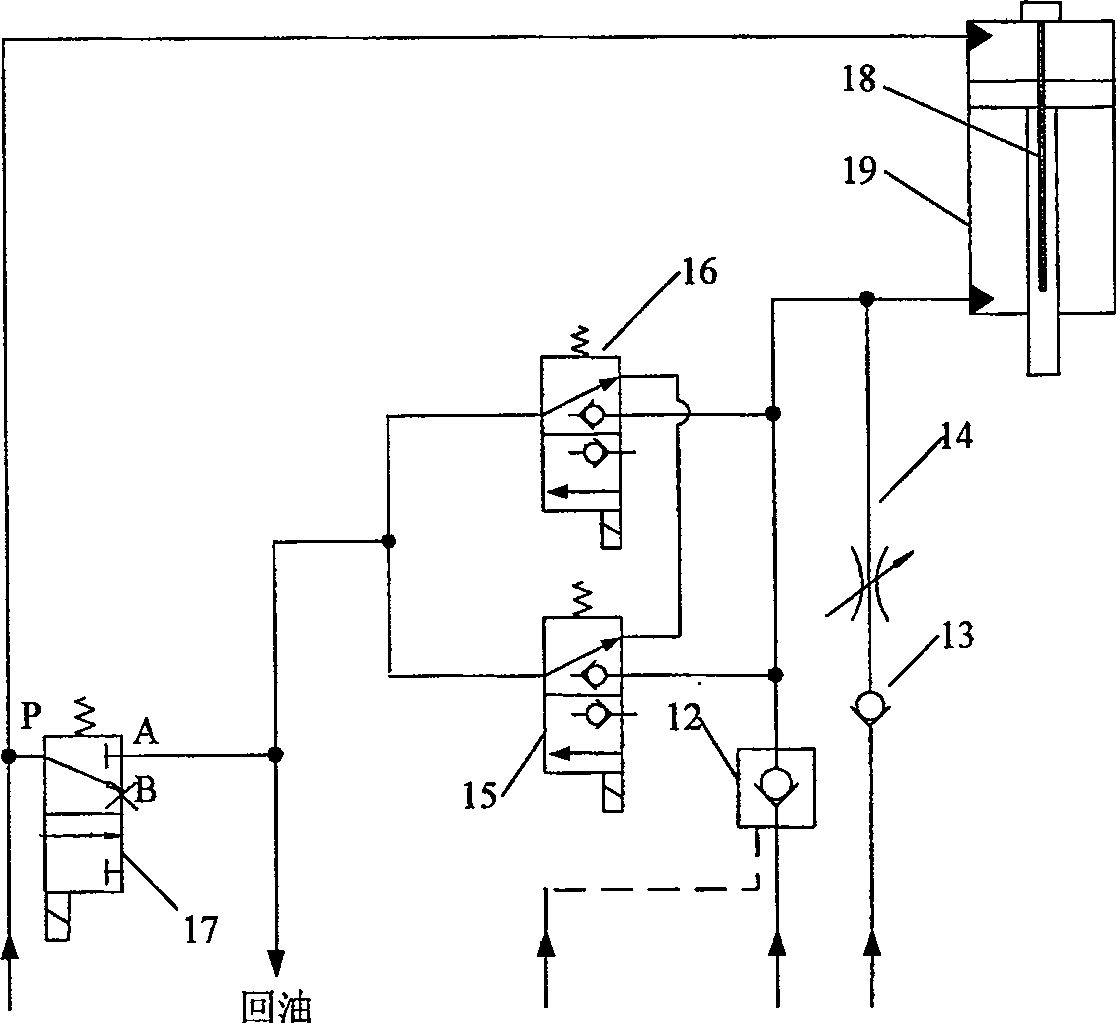

[0015] The system adopts the common control method of mechanical hydraulic synchronization and electrical synchronization to realize the synchronous lifting and speed control requirements of the cylinder valve of the water turbine.

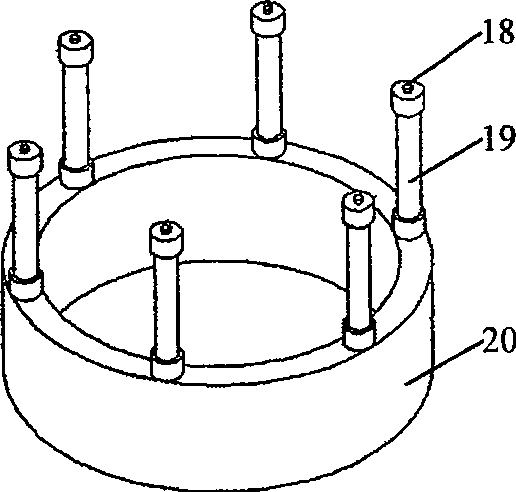

[0016] In this embodiment, six servomotors are used as the actuators of the hydraulic system. In order to realize the synchronous control technical requirements of the servomotor hydraulic cylinders, it is realized by ensuring that each servomotor hydraulic cylinder has an equal amount of oil in and out. At the same time, the motor used in this embodiment is a radial plunger hydraulic motor to divide the hydraulic oil, so as to ensure that the amount of oil in and out of each servomotor hydraulic cylinder is basically equal. Each shunt motor has two oil delivery pipes, one of which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com