Bandgap voltage reference circuit and method for producing a temperature curvature corrected voltage reference

A voltage reference and voltage generation circuit technology, applied in the direction of adjusting electrical variables, instruments, control/regulation systems, etc., can solve the problems of difficult Lewis circuits and limited temperature curvature calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

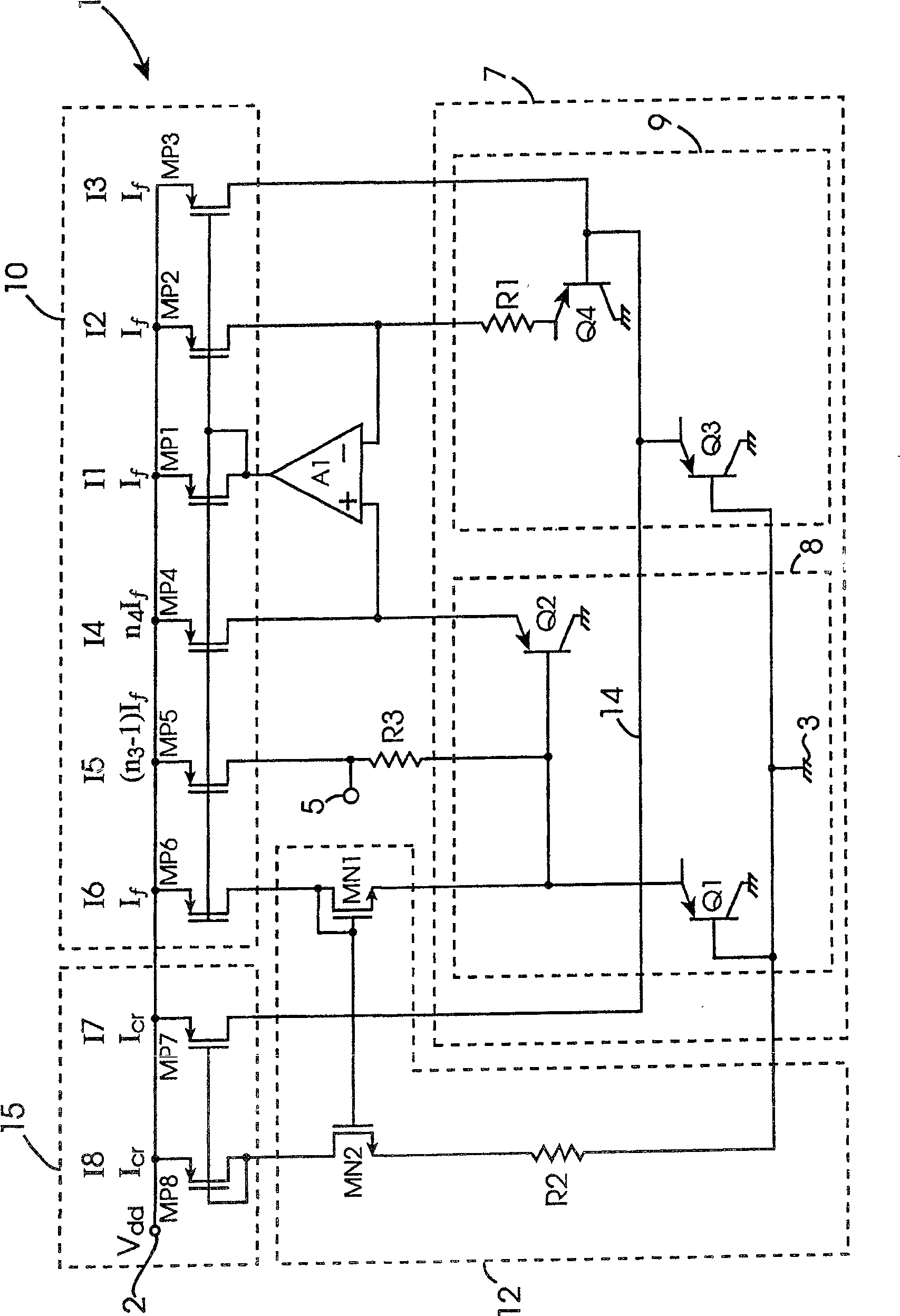

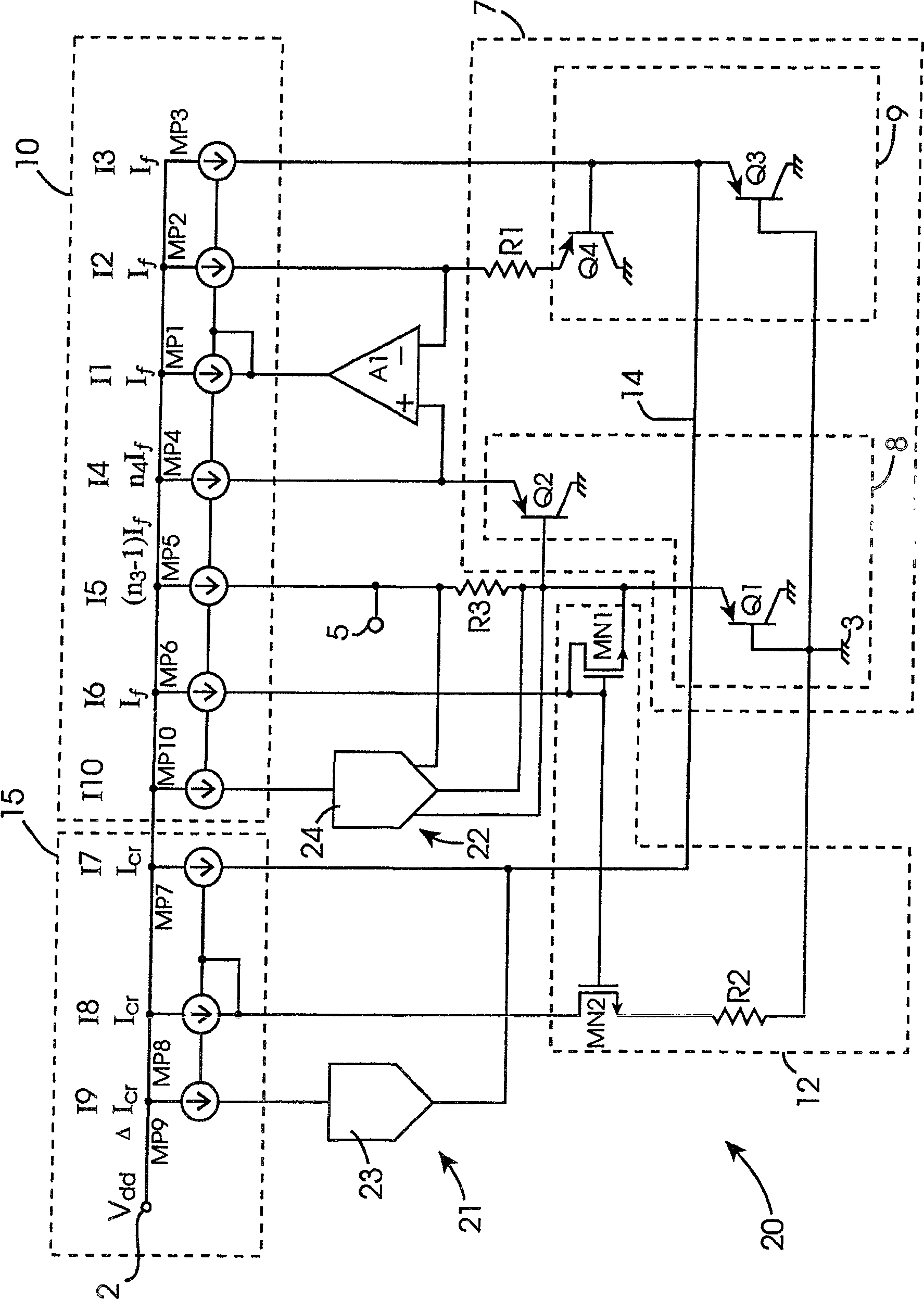

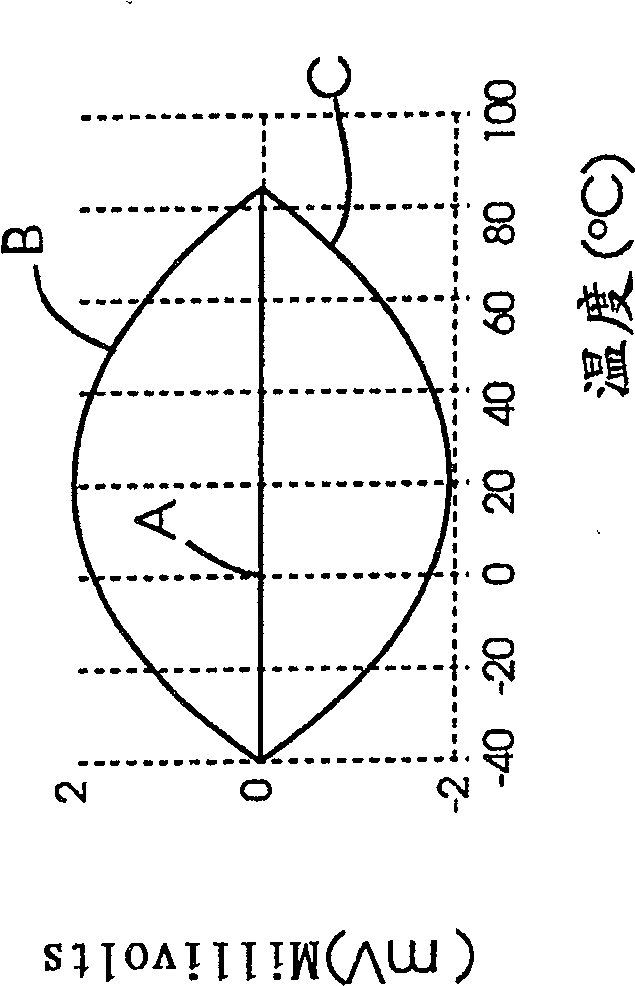

[0074] see first figure 1 , which shows a bandgap voltage reference circuit in accordance with the present invention, denoted by reference numeral 1, which can be used to provide a temperature stable and TlnT temperature curvature calibrated DC voltage reference output. The voltage reference circuit 1 is implemented on a silicon chip in the form of an integrated circuit using CMOS technology. The supply rail 2 of the voltage reference circuit 1 is loaded with a supply voltage Vdd, and the voltage reference circuit 1 is grounded at (number) 3 . A temperature stabilized and TlnT temperature curvature calibrated voltage reference is formed between output 5 and ground 3 .

[0075] The voltage reference circuit 1 includes a bandgap unit 7, which includes a first transistor stack 8, which contains two stacked transistors, that is, two first bipolar transistors Q1 and Q2, the bandgap The cell also includes a second transistor stack 9, which contains two stacked transistors, namely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com