Heat exchanger and outdoor unit of air-conditioner having the same

A technology for heat exchangers and outdoor units, which is applied in the field of outdoor units, and can solve problems such as the decrease in the efficiency of heat sinks, the expansion of the temperature difference between the end of the heat sink and the surface of the heat transfer tube, and the increase in distance, so as to achieve improved heat dissipation and condensation performance, and heat transfer The effect of increasing the amount and improving the heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

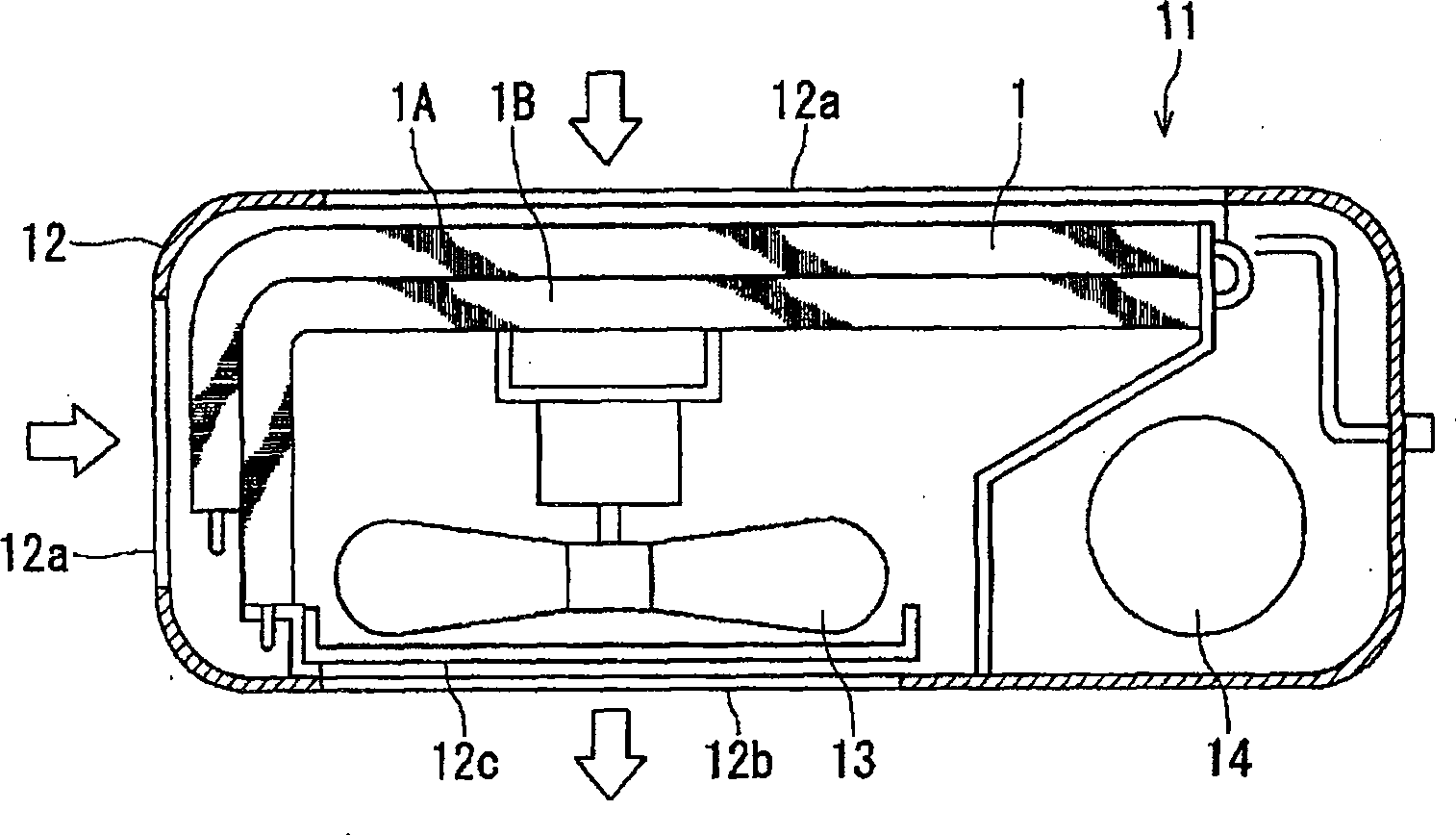

[0023] A heat exchanger according to an embodiment of the present invention will be described with reference to the drawings.

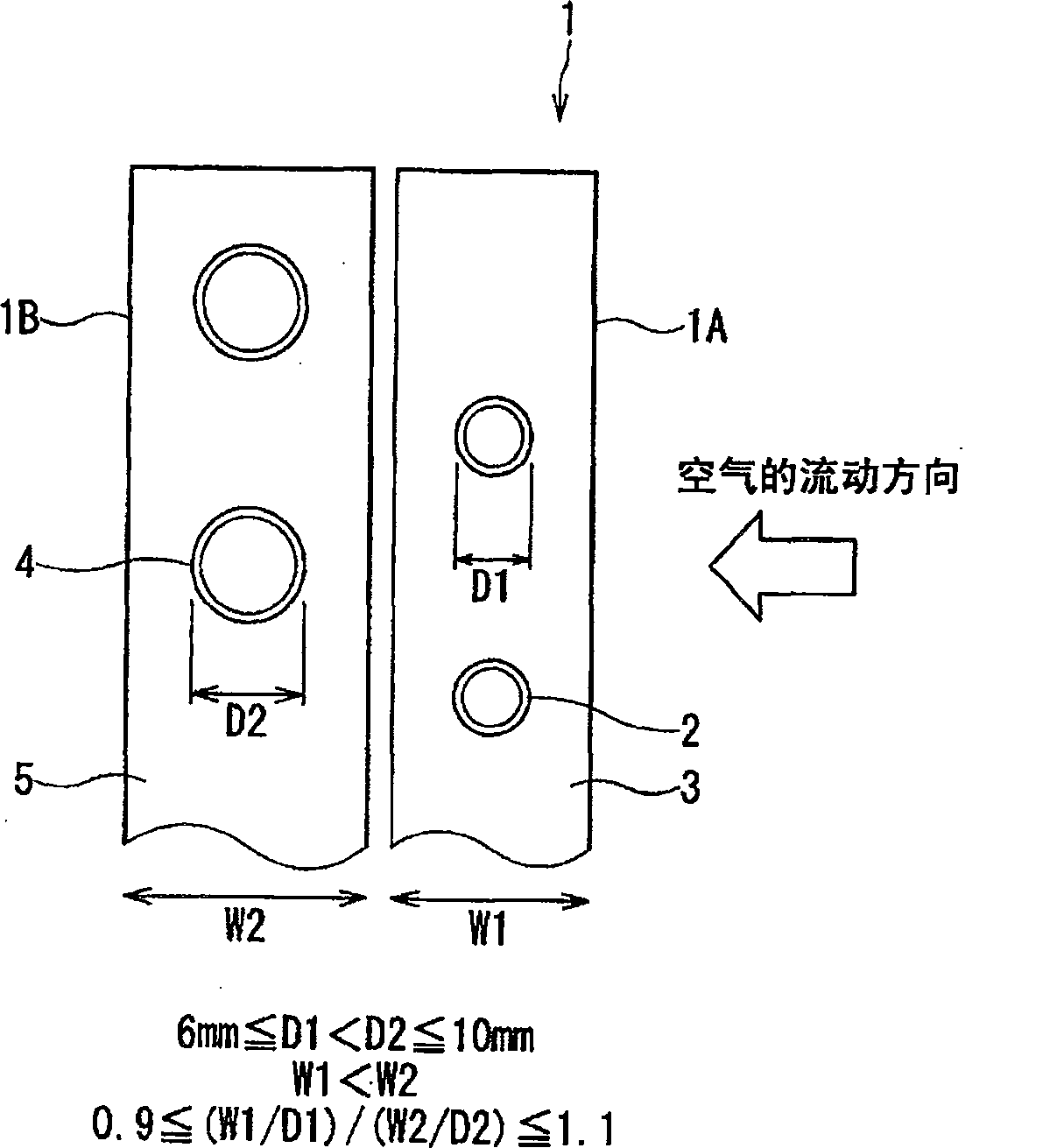

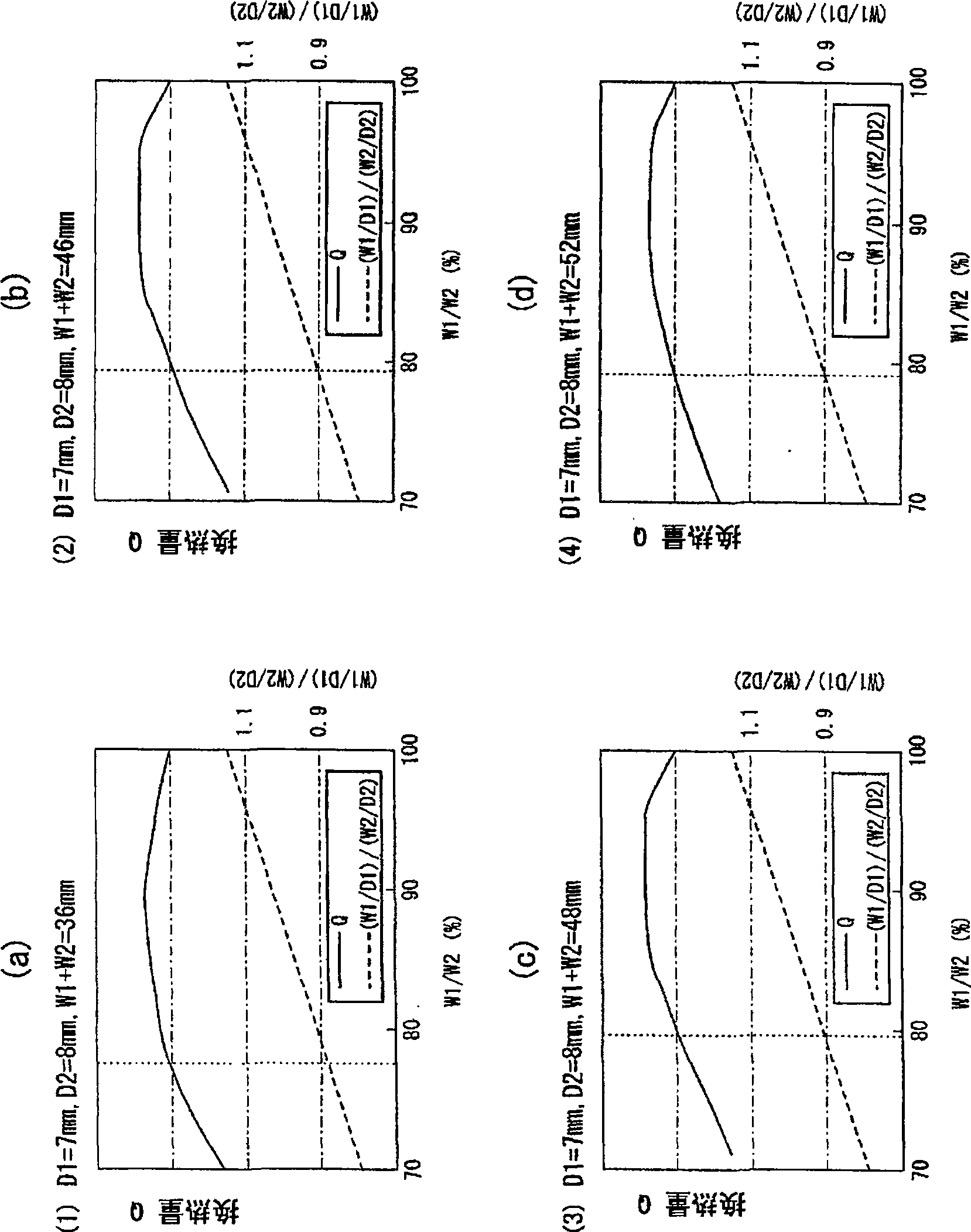

[0024] figure 1 It is a conceptual diagram of a heat exchanger according to an embodiment of the present invention.

[0025] like figure 1 As shown, the heat exchanger 1 of this embodiment is a fin-tube type heat-exchanger (fin-tubetype heat-exchanger), which has: an upper-wind side heat exchanger part 1A located on the upper side of the wind; The side heat exchanger unit 1A is separated from and disposed adjacent to the leeward side heat exchanger unit 1B located on the leeward side.

[0026] The upwind side heat exchanger unit 1A has small-diameter heat transfer tubes 2 as upwind heat transfer tubes arranged in a row in the airflow direction, and the small-diameter heat transfer tubes 2 are fitted side by side with a predetermined gap. A plurality of small-width cooling fins 3 that allow heat-exchanging air to flow along these gaps, and the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com