Automatic regulating arm for automobile braking

A technology for automatic adjustment of arms and automobile braking, applied in the field of transportation, can solve problems such as drag, inflexible adjustment, poor braking effect, etc., and achieve the effect of small resistance and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

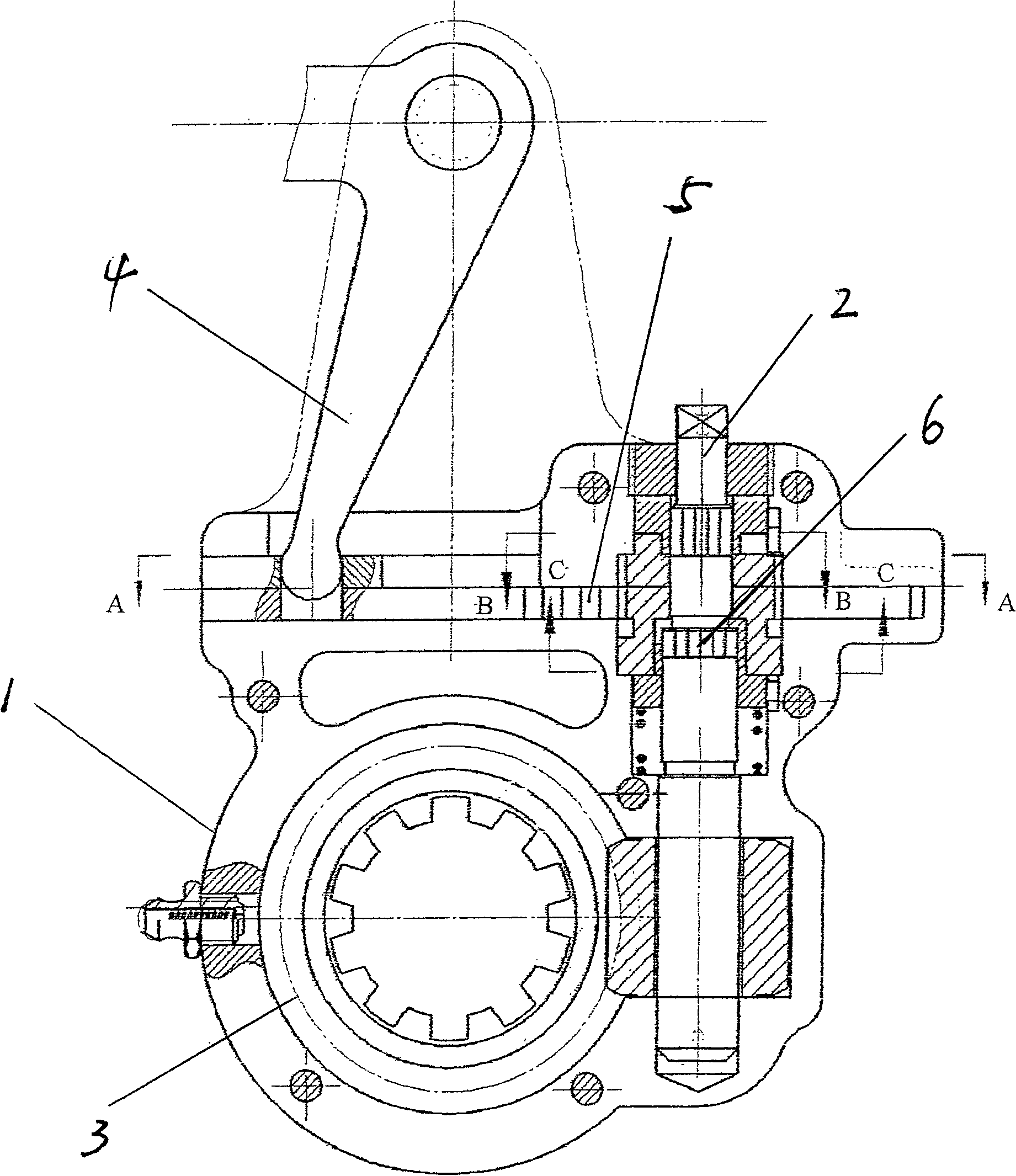

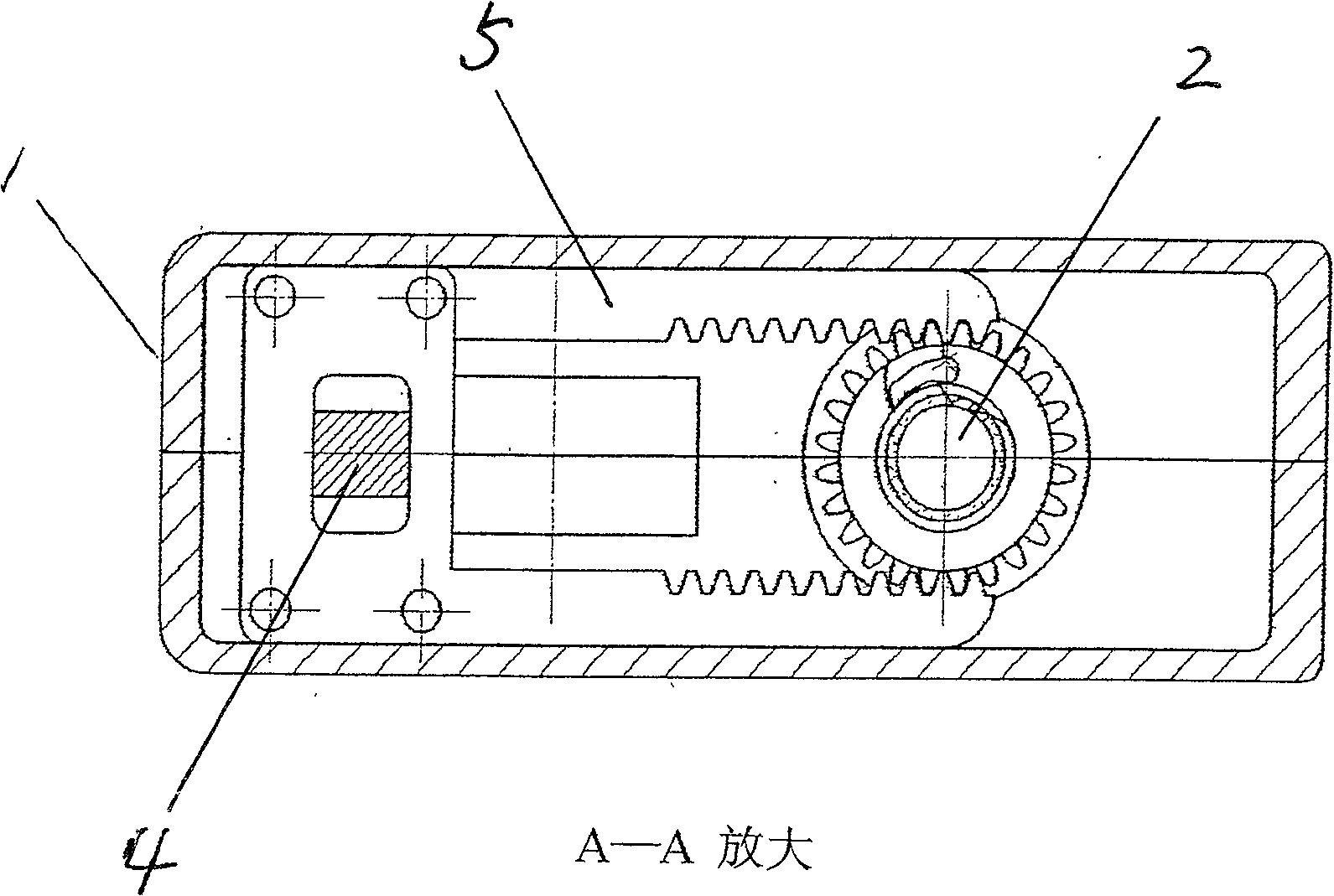

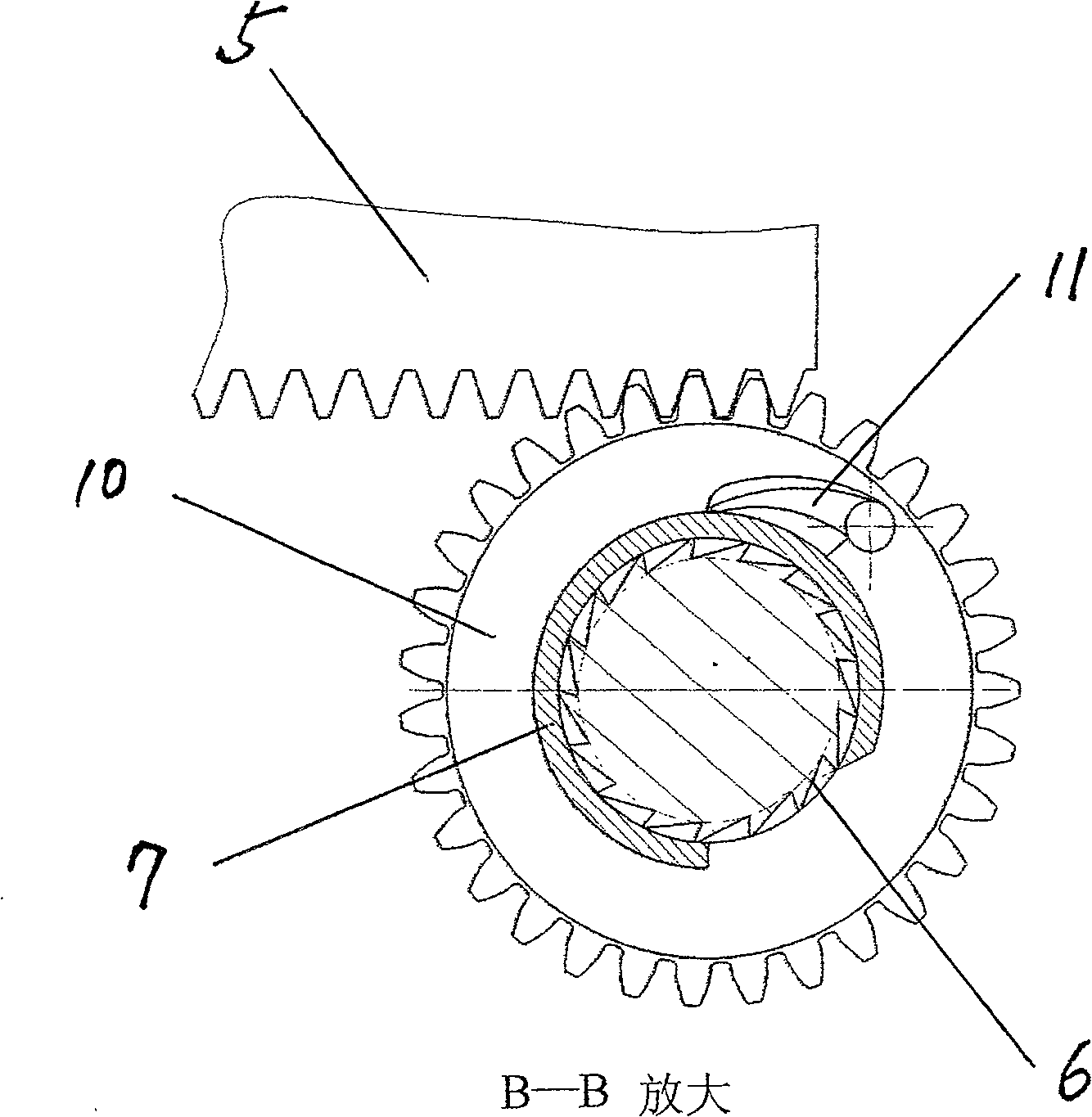

[0019] Embodiments of the present invention are given below in conjunction with the accompanying drawings.

[0020] made as figure 1 Shown is an adjustment arm comprising a housing 1 , a worm 2 , and a worm wheel 3 . Make the push rod and the adjustment arm as figure 1 Shown has the inflection shape of lever 4. Make one end to have two tooth bars 5 that driving rod stretches into hole, pack in the chute on the shell inner worm both sides housing. Two circles of ratchets 6 are processed on the worm, and the ratchets of the two circles of ratchets are obliquely opposite. Make the spacer sleeve 7 in the tubular thin-walled narrowing gap mechanism that axially has fracture and the spacer sleeve 8 in the expansion gap mechanism. The spacer 8 has a ring platform 8H and has a partially complete circumferential surface 8w. Put the spacer sleeve on the ratchet position on the worm. The isolation sleeve 7 is consolidated with the housing. The separating column 9 is fixed on the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com