Preparation process of high purity capsaicin

A capsaicin and high-purity technology, applied in the field of preparing capsaicin, can solve the problems of inability to realize industrialized production, complicated extraction and separation process, low yield and the like, and achieve the effects of easy recovery and reuse, simple production process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

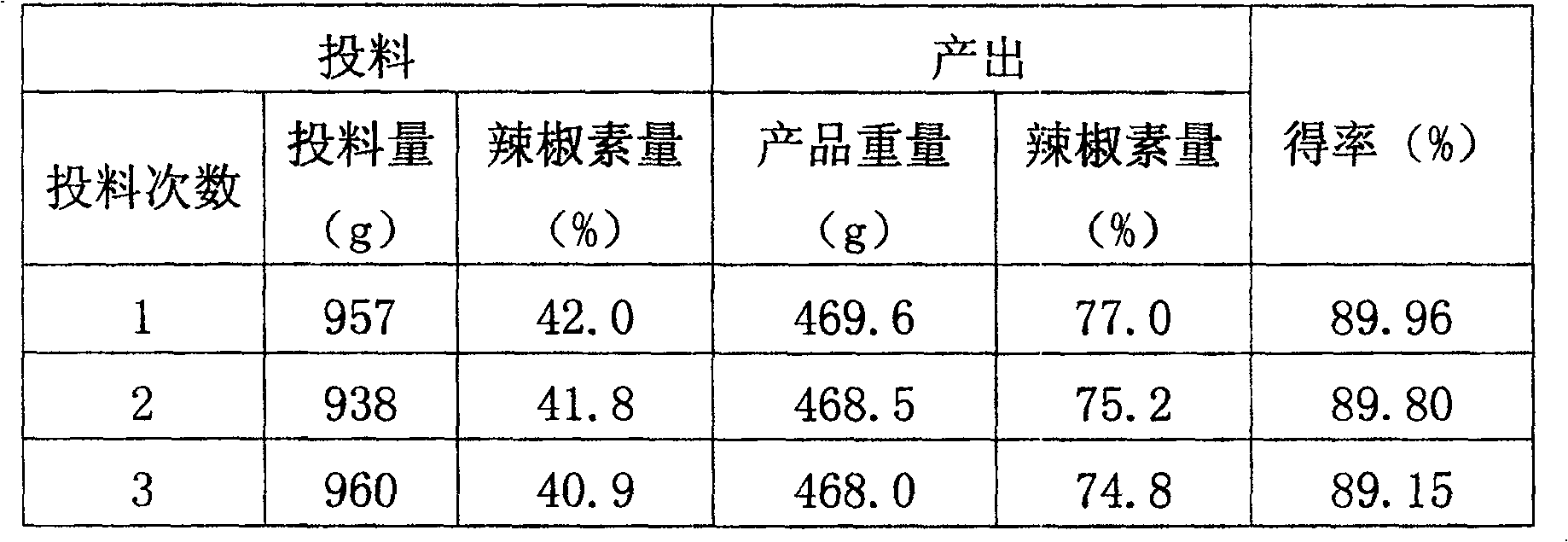

[0026] The specific embodiment of the present invention is divided into three steps and is processed and prepared into high-purity capsaicin.

[0027] Step 1: Extract the low-spicy capsicum essence through solvent extraction to prepare the medium-spicy capsicum essence.

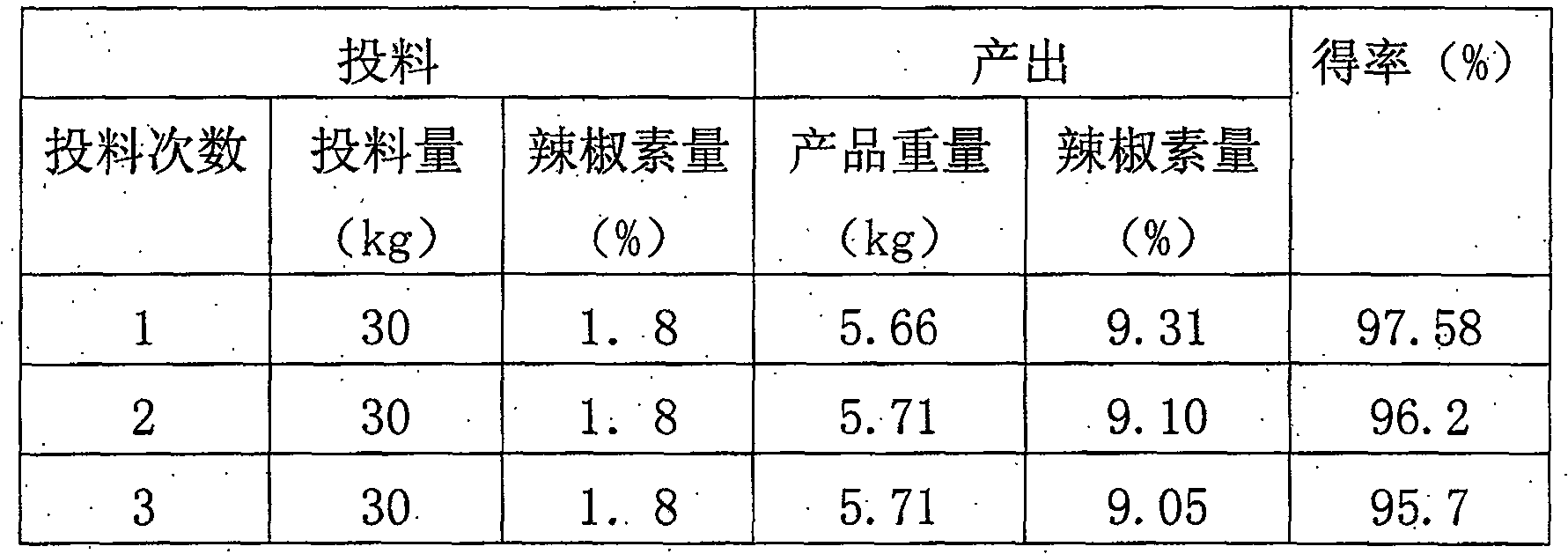

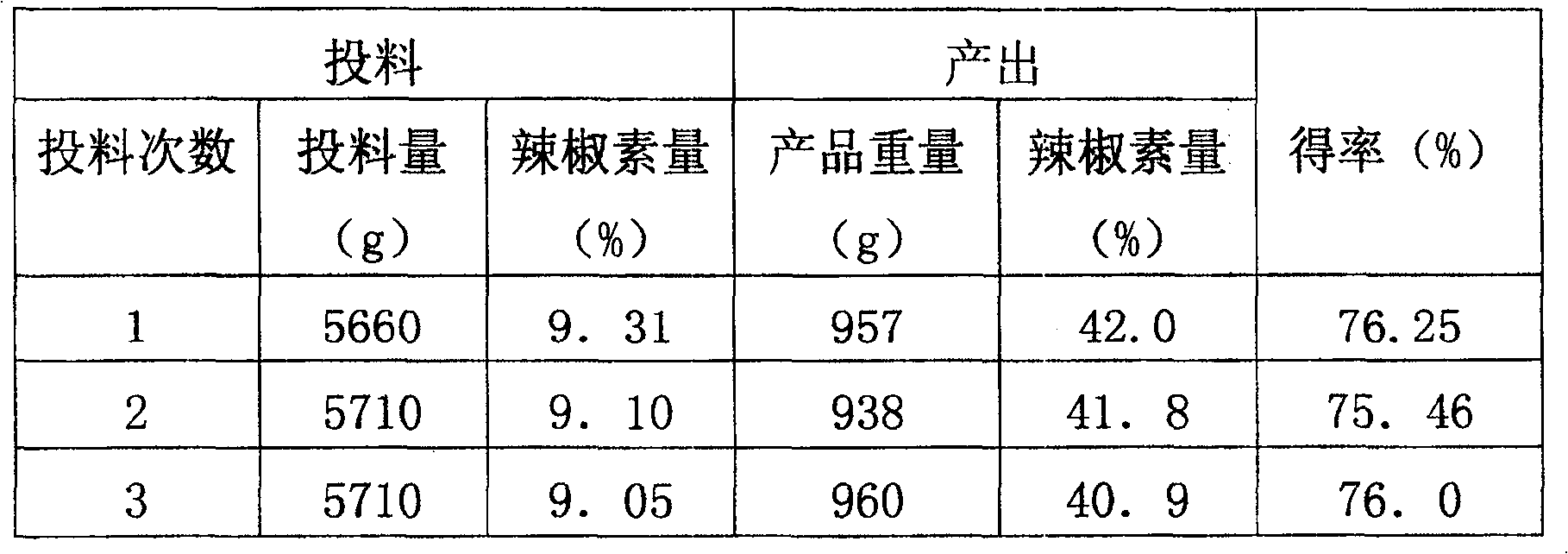

[0028] 1. Put 30kg of low-spicy capsicum extract with a spiciness of 1.8% into a stainless steel extraction reaction kettle, add 120kg of ethyl acetate, stir for 0.5 hours, pressurize into a stainless steel separation and precipitation tank for precipitation and separation; after 6 hours of precipitation and separation , put the precipitate back into the extraction reaction kettle, and pour the supernatant into the receiving tank to be evaporated.

[0029] 2. The precipitate in the extraction kettle is subjected to secondary extraction and precipitation separation; a total of three times.

[0030] 3. Combine the three extracts, pump them into the evaporator for vacuum evaporation and concentration, the evapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com