A kind of preparation method of soybean Dan peptide chelated calcium

A technology for chelating calcium and soybean Dan peptide, which is applied to the preparation method of peptides, chemical instruments and methods, peptides, etc., can solve the problems of decreased calcium bioavailability and unsatisfactory calcium supplementation effect, and achieve the goal of alleviating the national calcium deficiency The effects of pressure, improving efficiency and pertinence, and enhancing overall competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

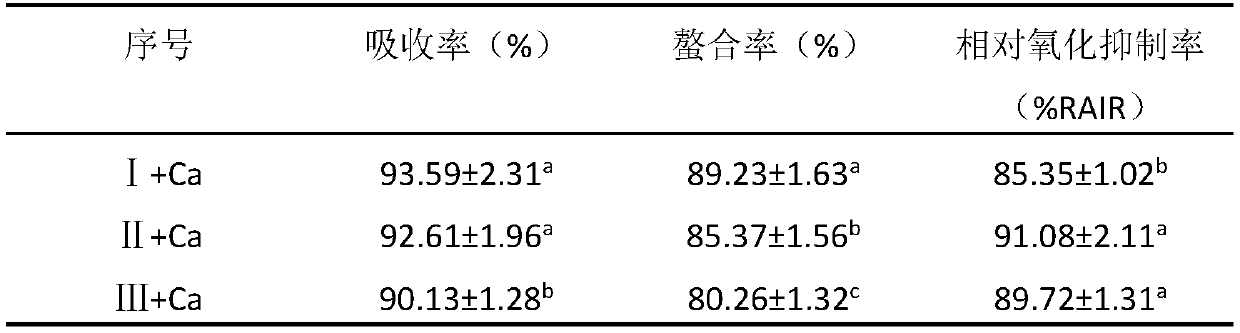

Embodiment 1

[0037] Using supercritical CO 2 Extraction and degreasing method is used to degrease soybean Dan, the extraction temperature is 40°C, CO 2 The flow rate is 25L / h, the pressure is 35Mpa, and the extraction time is 1.5h. Superfinely pulverize the defatted soy bean, mix according to the mass ratio of soy bean and water of 1:10, adjust to pH 7.5, temperature 40°C, add alkaline protease with 0.5% mass of soy bean to enzymatically hydrolyze the soy bean 12h, the enzymolysis solution was stirred at a speed of 40 rpm. After the enzymatic hydrolysis, the enzymatic hydrolysis solution was heated to 75°C for 20 minutes to inactivate the protease. The enzymatic solution was centrifuged at 10,000 rpm for 20 minutes, and the supernatant was taken. The supernatant was removed by an ultrafiltration membrane with a molecular weight cut-off of 300kD to obtain a purified liquid. The purified solution is separated and purified by ultrafiltration membranes with molecular weight cut-offs of 5kD...

Embodiment 2

[0070] Using supercritical CO 2 The extraction and degreasing method is used to degrease soybean Dan, the extraction temperature is 45°C, CO 2 The flow rate is 15L / h, the pressure is 20Mpa, and the extraction time is 3h. Superfinely pulverize the defatted soy bean, mix according to the ratio of soy bean and water mass ratio of 1:15, adjust to pH4, temperature 30°C, add 0.3% neutral protease of soy bean mass to enzymatically hydrolyze the soy bean for 20 hours . The enzymatic solution was stirred at a speed of 50 rpm. After the enzymatic hydrolysis, heat the enzymatic hydrolysis solution to 80°C for 10 minutes to inactivate the protease. The enzymatic solution was centrifuged in a centrifuge at 8000 rpm for 30 minutes, and the supernatant was taken. The supernatant was removed by an ultrafiltration membrane with a molecular weight cut-off of 200kD to obtain a purified liquid. The purified solution is separated and purified by ultrafiltration membranes with molecular weight...

Embodiment 3

[0072] Using supercritical CO 2 The extraction and degreasing method is used to degrease soybean Dan, the extraction temperature is 45°C, CO 2The flow rate is 15L / h, the pressure is 10Mpa, and the extraction time is 1-4h. Superfinely pulverize the defatted soy bean, mix evenly according to the ratio of soy bean and water mass ratio of 1:20, adjust to pH8, temperature 20°C, add a compound enzyme of trypsin and alkaline protease with 1% of bean mass to treat the bean. Dan was subjected to enzymatic hydrolysis for 18 hours, wherein the weight ratio of trypsin and alkaline protease was 1:2. The enzymatic solution was stirred at a speed of 25 rpm. After the enzymatic hydrolysis, heat the enzymatic hydrolysis solution to 85°C for 10 minutes to inactivate the protease. The enzymatic solution was centrifuged in a centrifuge at 12,000 rpm for 10 minutes, and the supernatant was taken. Use an ultrafiltration membrane with a molecular weight cut-off of 250Kd to remove impurities with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com