Process for manufacturing Chinese mugwort leaf functional paper

A manufacturing process, the technology of mugwort leaves, applied in the field of mugwort functional paper manufacturing technology, can solve the problems of long storage life, etc., and achieve the effects of prolonging the storage life, increasing health care, and preventing skin itching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

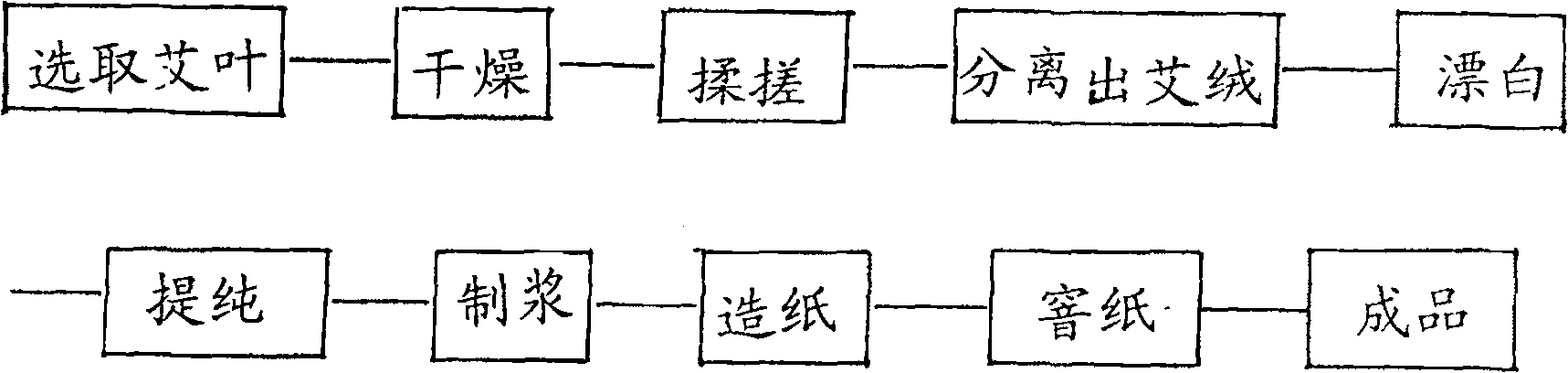

[0011] Embodiment 1 of Artemisia argyi functional paper manufacturing process of the present invention, see figure 1 , in its technological process, using mugwort leaves as raw materials, select mugwort leaves in the mid-growth period from May to June, dry them in a dryer or expose them to sunlight, and the water content is less than 8%, knead the dried mugwort leaves into powder, and use Centrifugal sieve separates moxa and crumbs, takes moxa and bleaches it according to the traditional papermaking process, and then washes to remove impurities to improve the purity of moxa. Mix it with moxa oil and put it in a space for 1-3 hours to make the paper evenly absorb the moxa oil.

[0012] Embodiment 2 of the manufacturing process of Artemisia argyi functional paper of the present invention, see figure 1 , in its technological process, the bleaching and moxa purification steps are removed, and the moxa is directly pulped to meet certain needs, such as orthopedic paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com