Steel-concrete combined structure double-deck continuous girder bridge

A combined structure and steel-concrete technology, applied to bridges, bridge parts, bridge materials, etc., can solve the problems of affecting the aesthetic feeling of urban buildings, uncoordinated bridge site environment, rigidity, etc., to achieve effective use of structural space, reduce road space pressure, The effect of reducing the overall width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

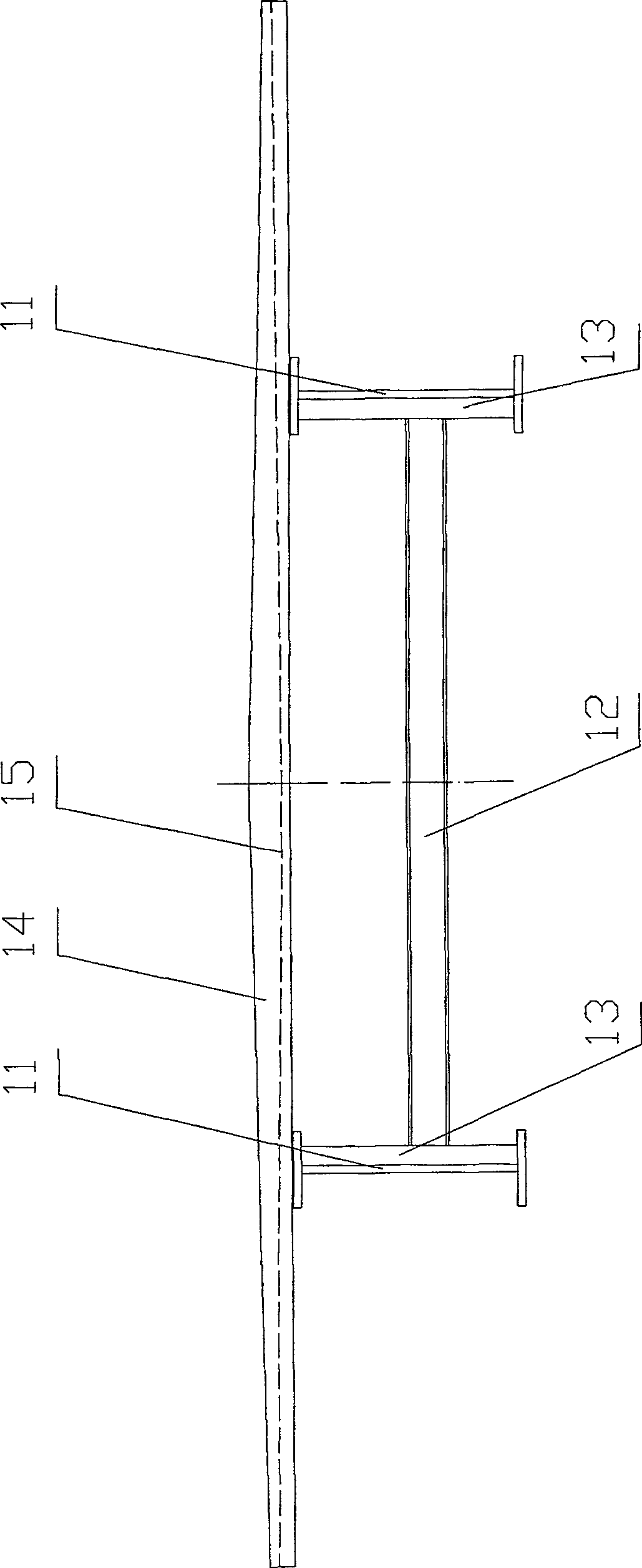

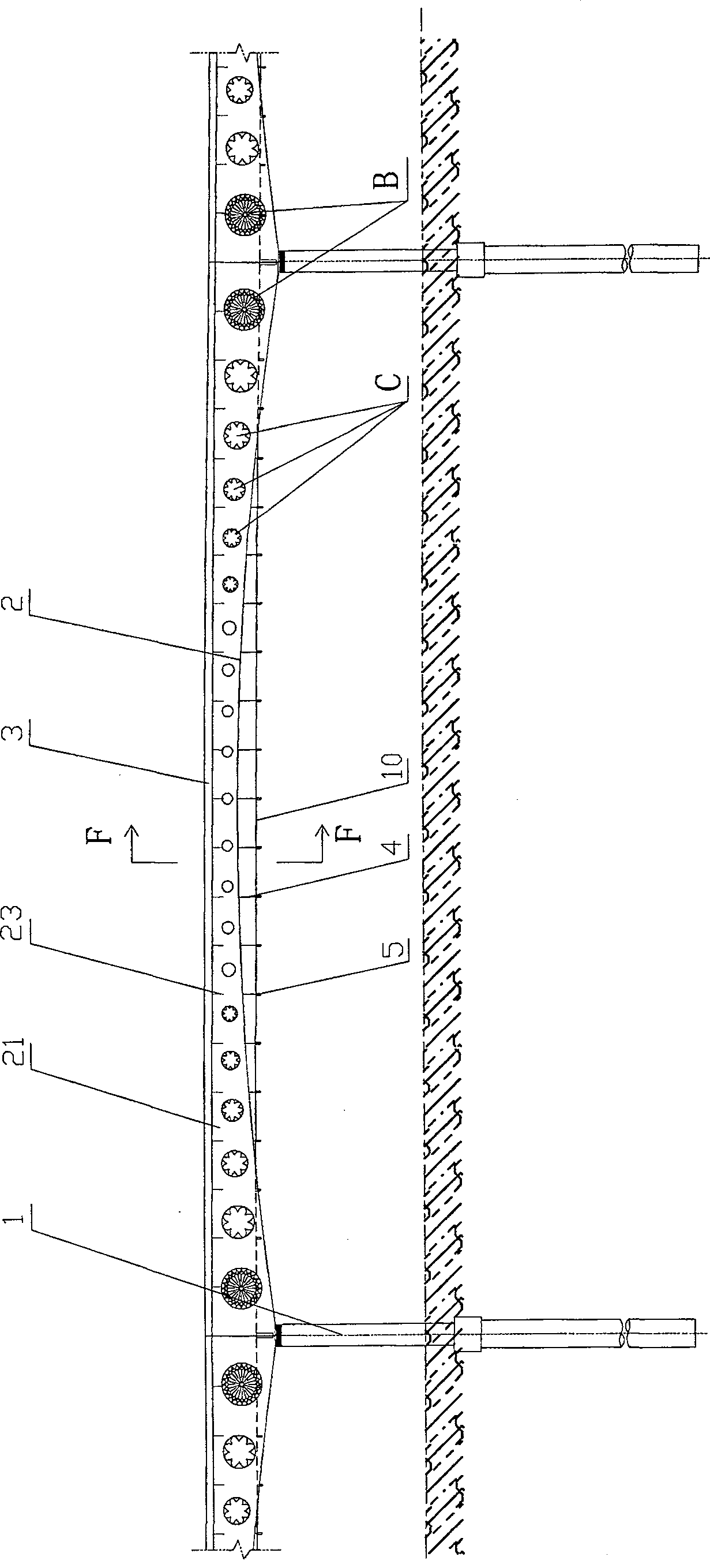

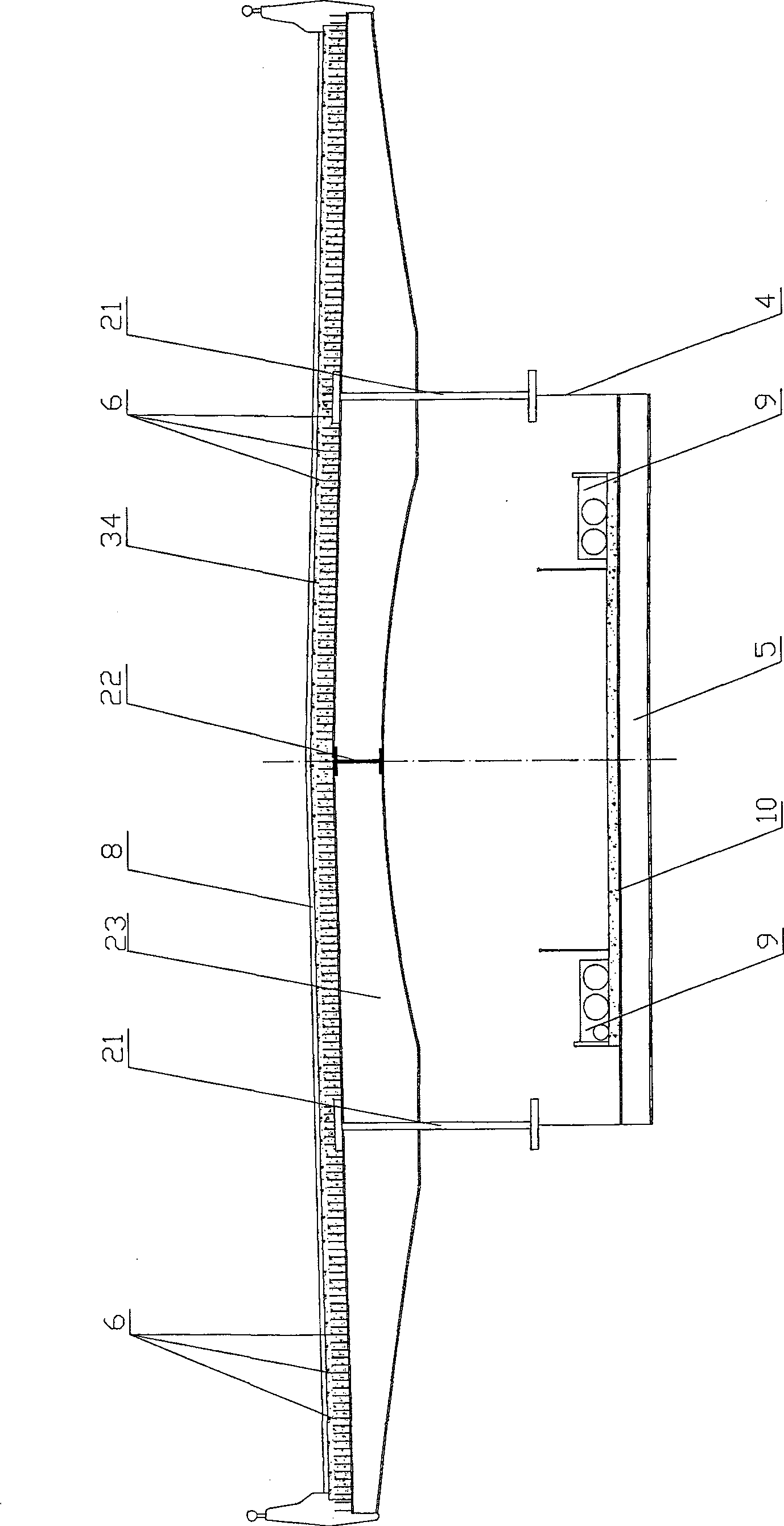

[0052] Such as Figure 2 to Figure 14 As shown, the double-layer continuous girder bridge with steel-concrete composite structure of the present invention combines the characteristics of steel truss girder and traditional steel plate girder composite structure, and it includes pier 1, steel girder 2 and bridge deck 3, and pier 1 supports steel girder 2 , the steel girder 2 supports the bridge deck 3, wherein the steel girder 2 is mainly composed of a hollow steel web 21, a small longitudinal beam 22 and a cantilever-type upper beam 23, and the bridge deck 3 is a prefabricated low-rib bridge deck Plates 35 are assembled and connected by joints. The steel web 21 adopts an I-beam structure, and the inner side of the steel web 21 is provided with vertical stiffeners 13 at a certain interval (see Figure 6 ) to strengthen its local stiffness. The small longitudinal girder 22 is located below the longitudinal centerline of the bridge deck 3. According to the load on the bridge and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com