Semiconductor material with 110 crystal tropism silicon-containing layer and its forming method

A crystal orientation, silicon semiconductor technology, used in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., to solve problems such as nFETs having no benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention provides a semiconductor material comprising a silicon-containing layer having a crystal orientation and biaxial compressive strain, as well as various methods of forming the material, which will now be referred to by reference to the appended Fig. is described in more detail.

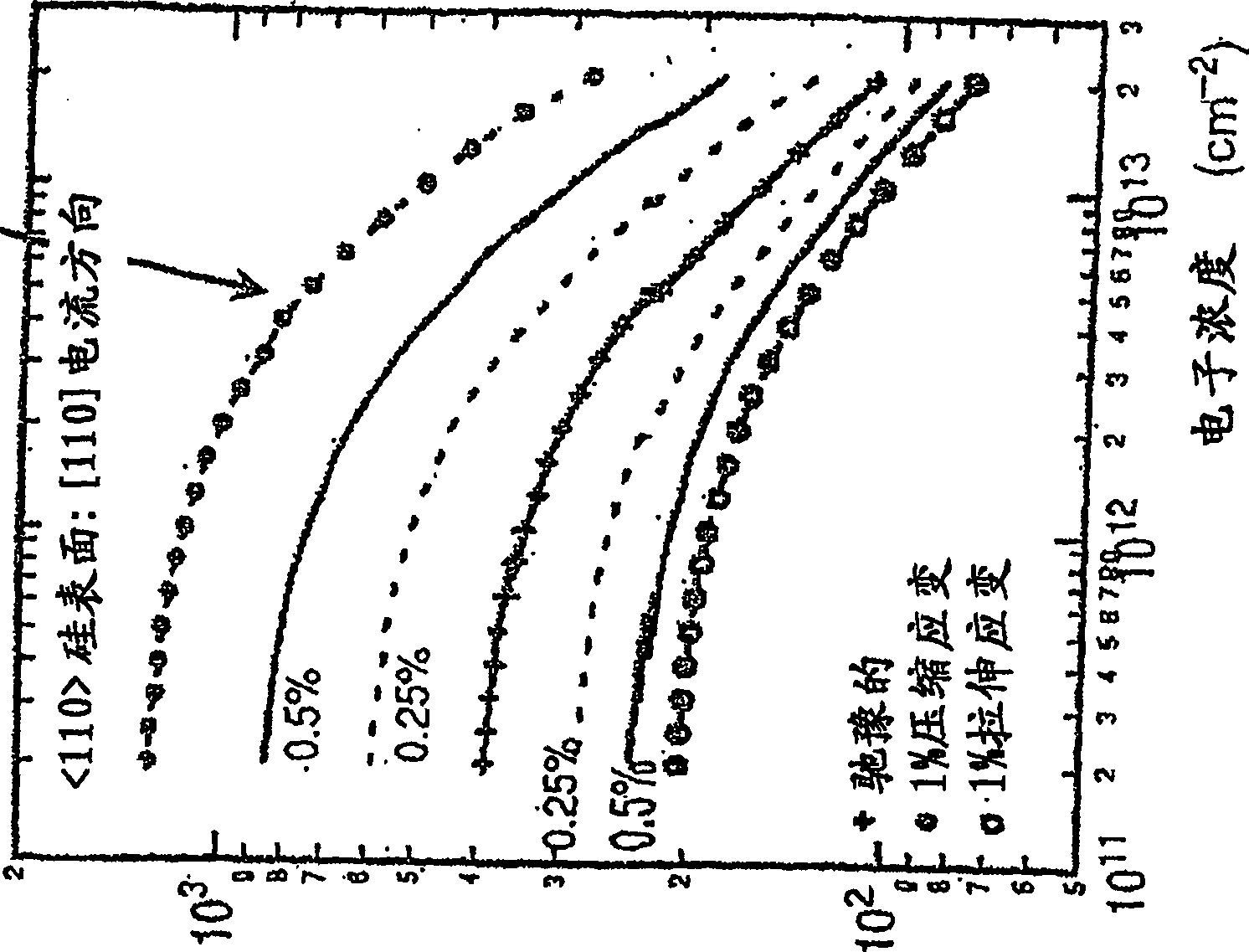

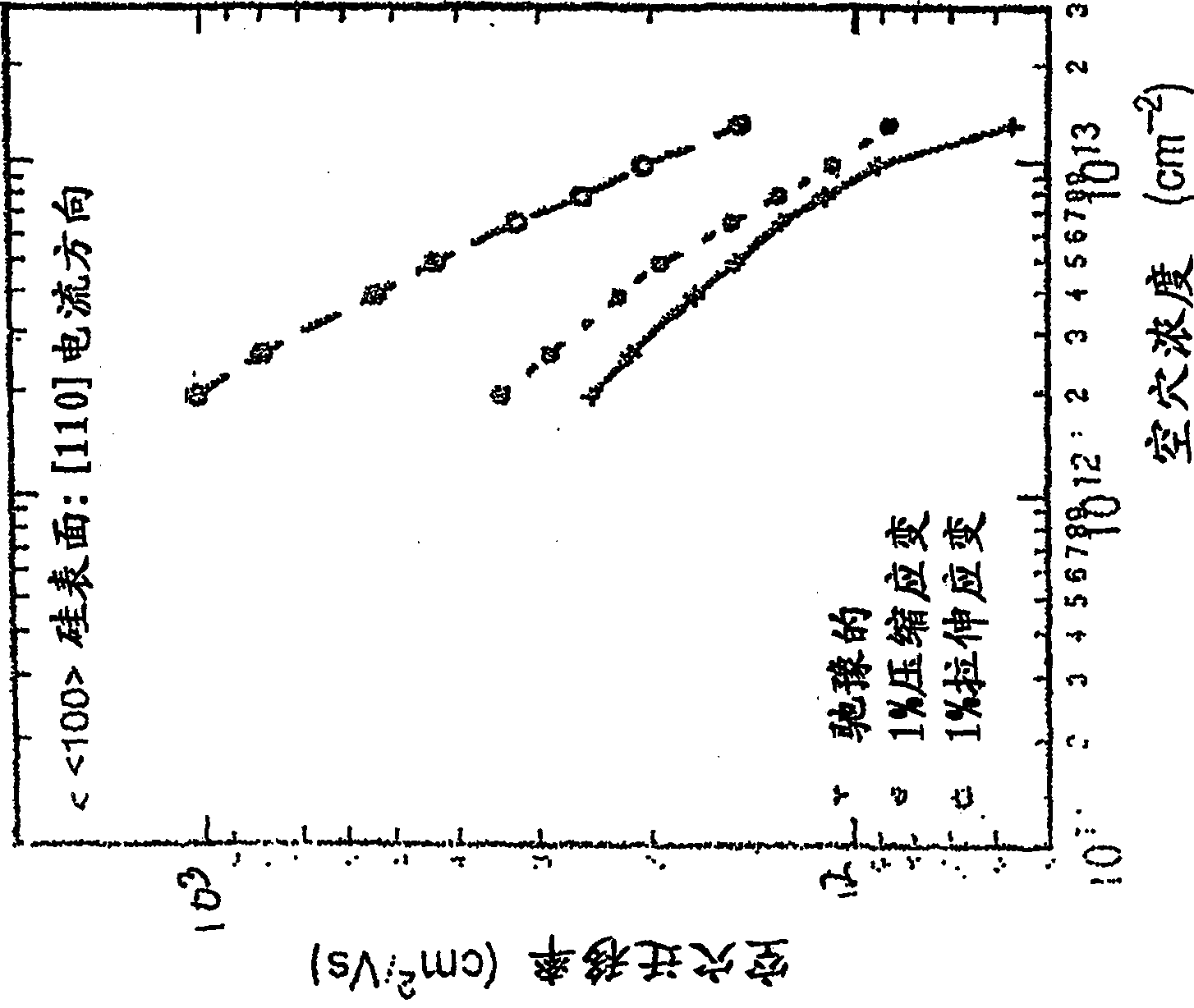

[0036] The applicants of the present application have determined by numerical calculations that when significant (greater than about 0.2%, preferably greater than about 0.5%) biaxial compressive strain is introduced onto a silicon-containing layer, electron and hole mobilities exceed conventional The case of unstrained silicon . Strain percent is defined herein as the percent change in the lattice constant of a material in a given direction. The significant advantages of the combination of biaxial compressive strain and silicon-containing layers have not previously been recognized in the art.

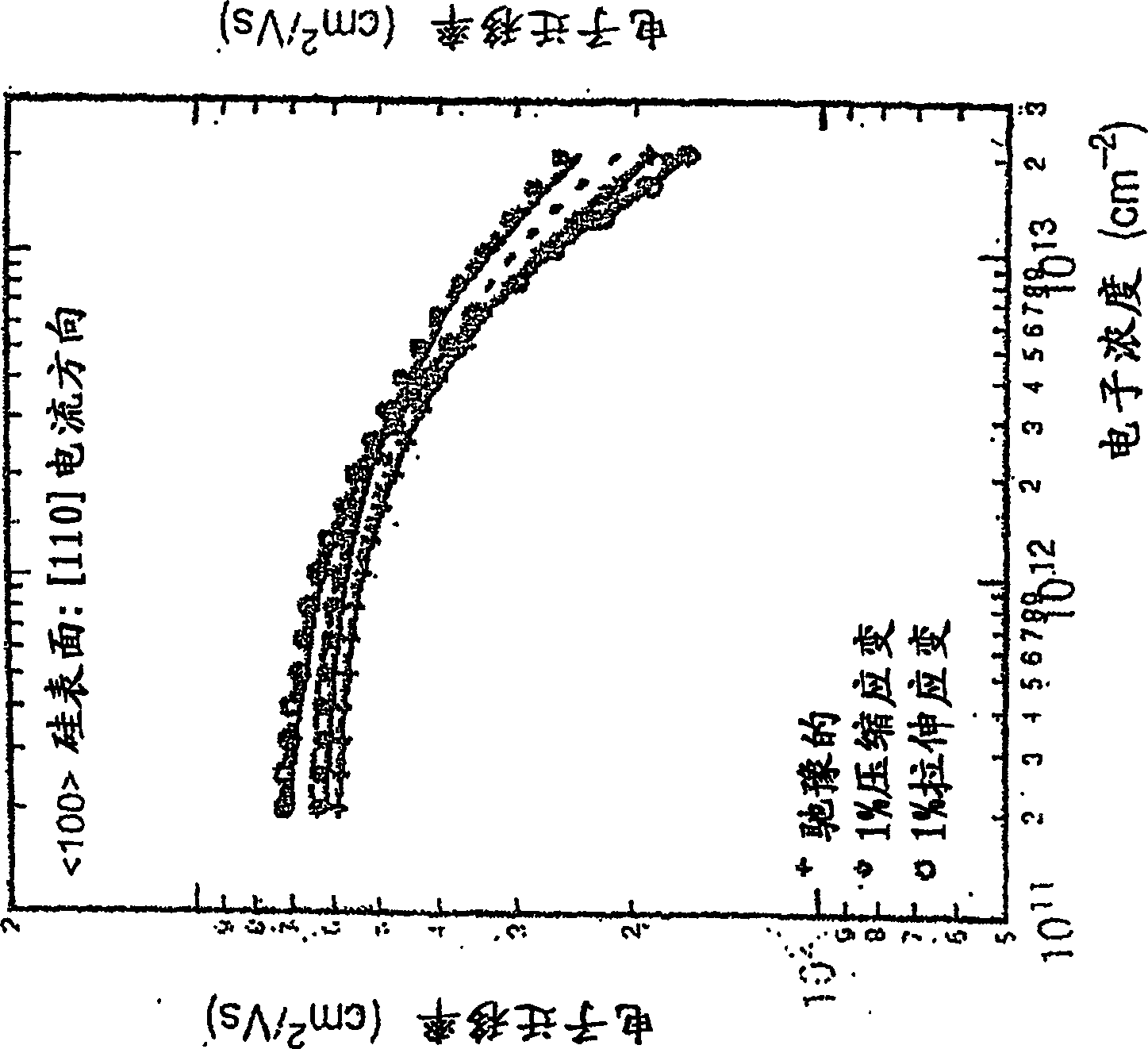

[0037] The result of the above calculation is in Figures 1A-1B and Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com