Super high molecular weight polythene/polypropylene/organic clay composition used for extraction formation and preparation method thereof

An ultra-high molecular weight, extrusion molding technology, applied in the field of polymer processing, can solve the problems of expensive manufacturing and poor adaptability of different grades of raw materials, and achieve the effects of increased tensile strength, improved processing rheology, and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

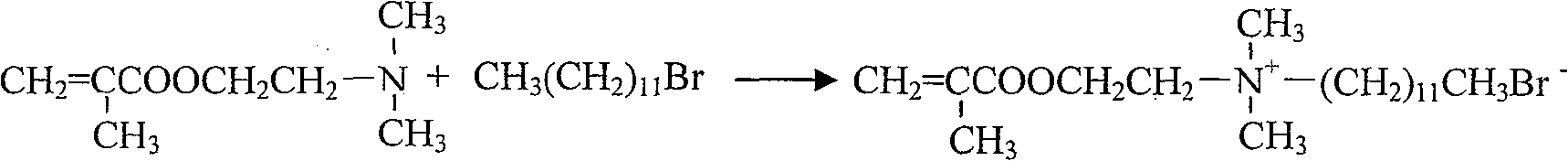

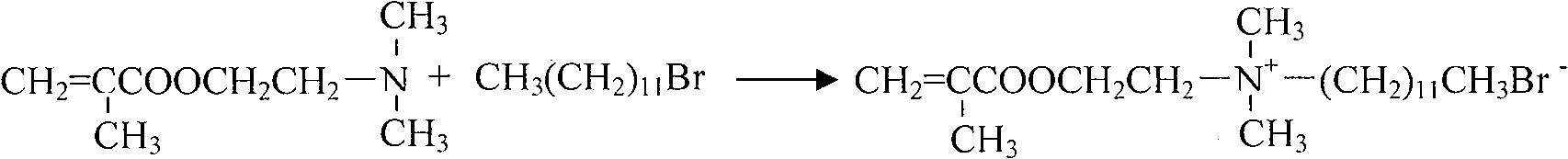

[0033] Example 1: Add dodecyl bromide and dimethylaminoethyl methacrylate in a molar ratio of 1:1 into a three-necked bottle with a stirrer and a condenser, and react for 90 hours in a constant temperature water bath at 50°C. The reactant was cooled to room temperature, poured into a beaker, added 12 times the anhydrous ether of the reactant, stirred, and stood still. After the silver-white crystals were completely precipitated at the bottom of the bottle, the upper layer of ether was separated, and the solid product was obtained by suction filtration. Wash the crystals repeatedly until the ether is colorless, then recrystallize the product with ethyl acetate to remove unreacted raw materials and polymerization inhibitors, and put the obtained product in a vacuum oven with a vacuum degree of 10 4 Pa, dried at room temperature to constant weight to obtain methacryloyloxyethyl dodecyldimethyl ammonium bromide (MDAB).

[0034] Add 100g of MDAB, 100g of polyethylene glycol with a ...

Embodiment 2

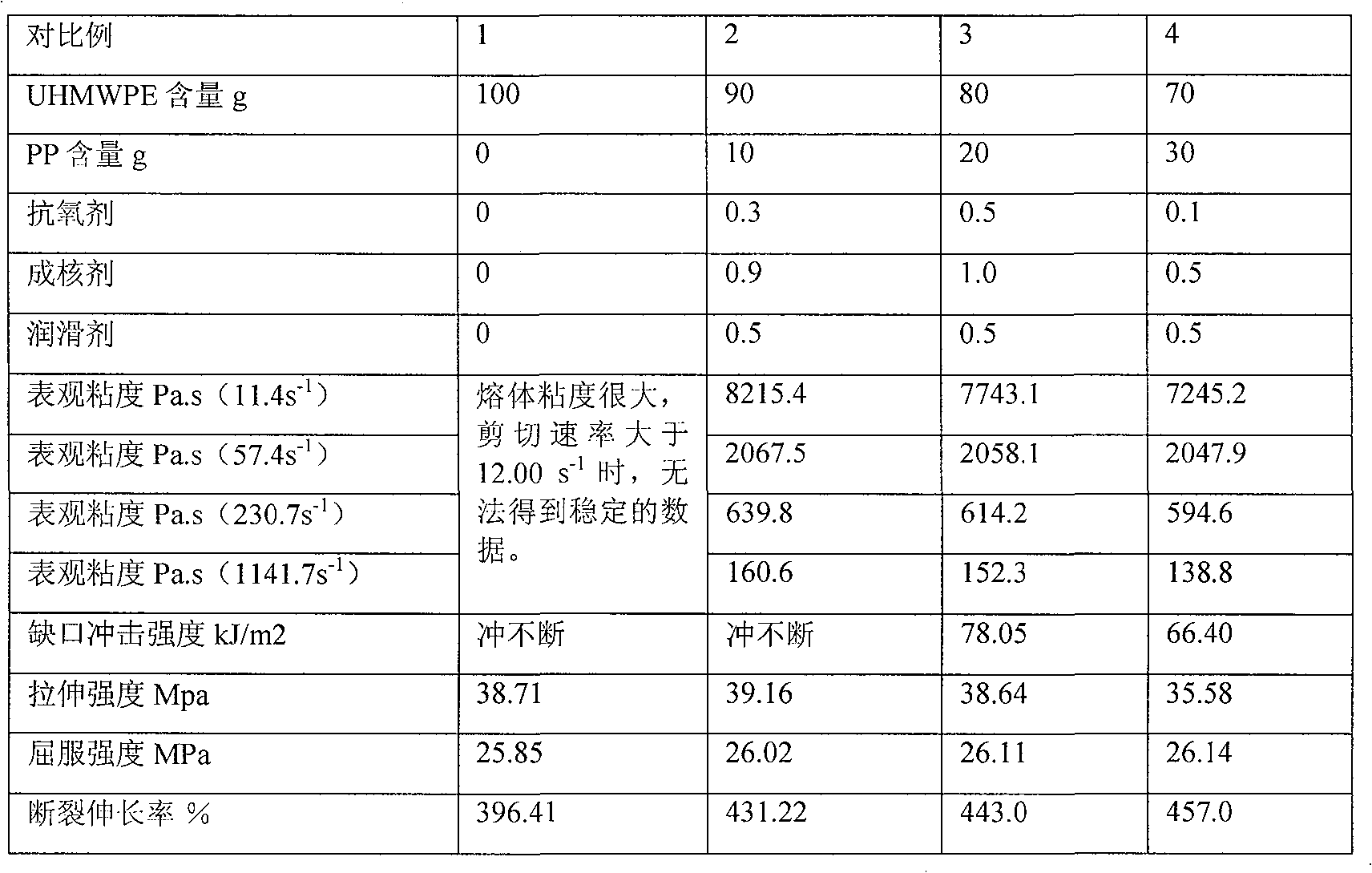

[0035] Example 2: Mix 13g of composite processing aid PMM, 0.9g of talcum powder, 0.3g of 4-hydroxymethyl-2,6-di-tert-butylphenol and 0.5g of oxidized polyethylene wax, and use twin-screw extrusion to granulate . All the other components and operating conditions are with embodiment 1 in the formula. The results are shown in Table 1.

Embodiment 3

[0036] Example 3: Mix 15g of composite processing aid PMM, 0.5g of talcum powder, 1.0g of 4-hydroxymethyl-2,6-di-tert-butylphenol and 1.0g of oxidized polyethylene wax, and use twin-screw extrusion to granulate . All the other components and operating conditions are with embodiment 1 in the formula. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com