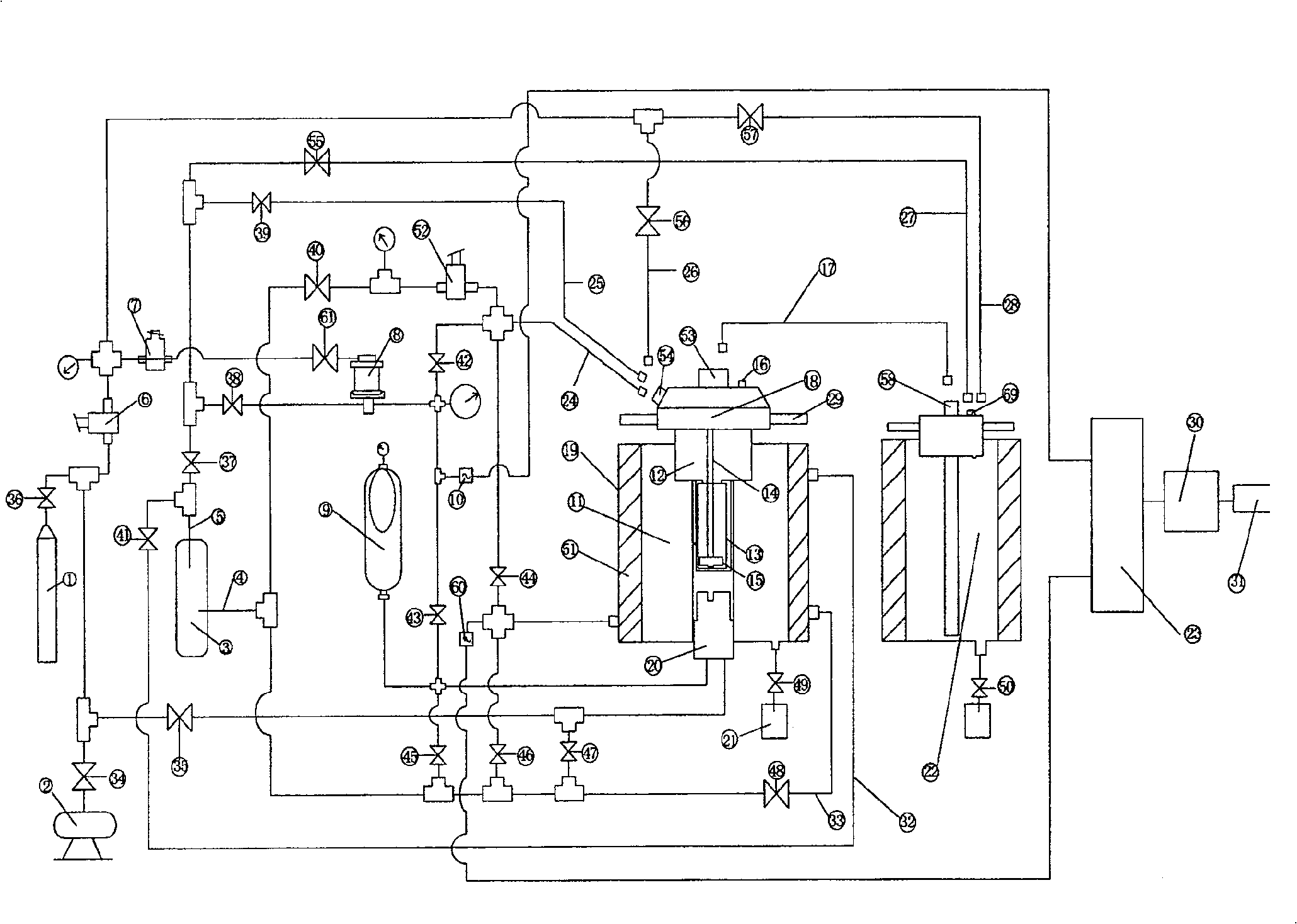

High-temperature high-pressure clay cake interface agglutination simulating-estimating device

A high-temperature, high-pressure, simulation evaluation technology, applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve problems such as lack, achieve stable performance, prevent interlayer channeling, and optimize formula design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The device of the present invention and its application are further explained below in the form of embodiments.

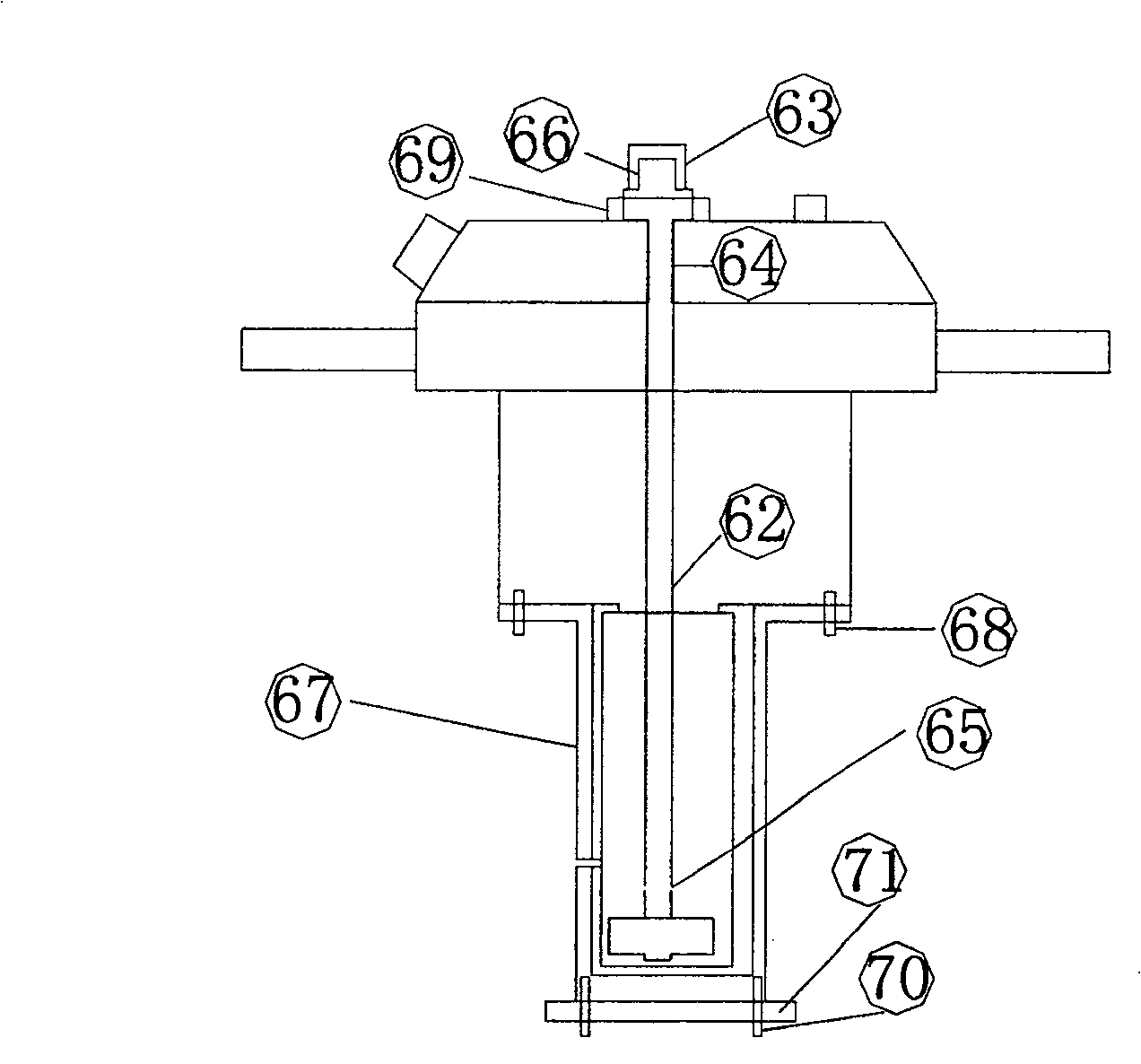

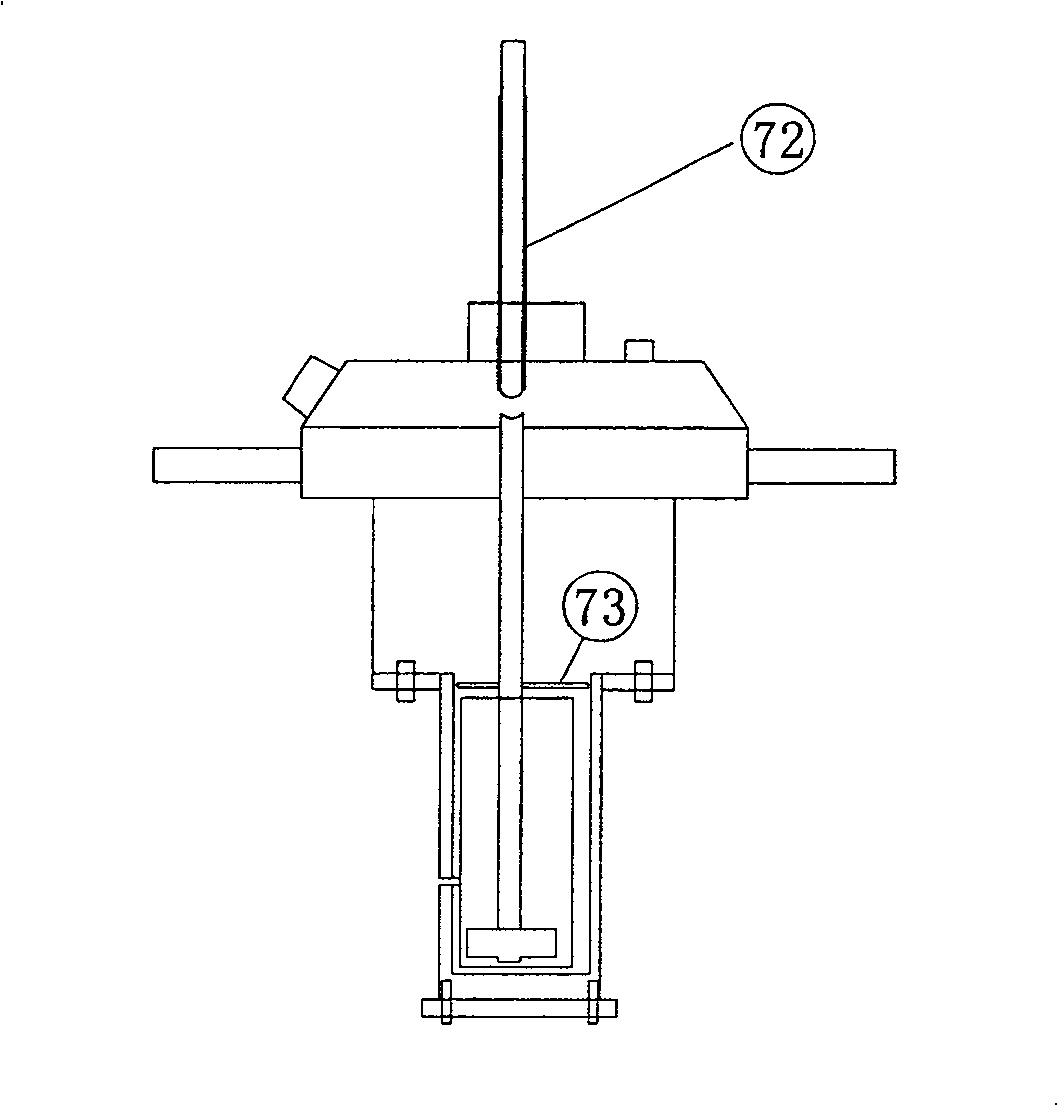

[0044] The high temperature and high pressure mud cake cementation quality evaluation system of the present invention has been debugged and applied to the experiment. In this embodiment, in order to fully explain the device of the present invention, this embodiment includes a relatively large number of operation steps, mainly including: installation of simulated wellbore, addition of drilling fluid and dehydration under pressure, displacement cleaning experiment, simulated casing Installation and experimental steps such as cementing fluid injection, heating and pressure curing, shear bond strength test, hydraulic bond strength test, etc., but the operation steps of the device of the present invention are not limited to it, and can be properly selected according to needs.

[0045] 1. Preparation before the test

[0046] All valves, pressure switches, etc. ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com