Heat preserving and bearing air-entrained brick for factory building

A kind of technology of aerated bricks and workshops, applied in the field of construction mortar, can solve the problems of easy water absorption and cracking, and achieve the effect of simple process and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

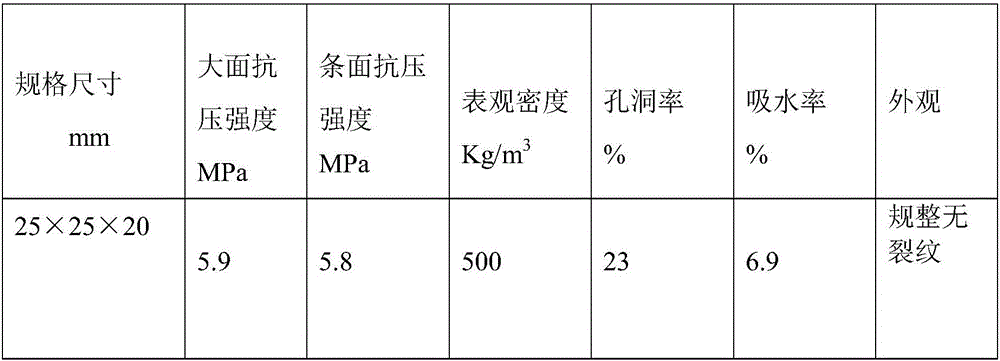

Examples

Embodiment Construction

[0009] An aerated brick for thermal insulation and load-bearing factory buildings, which consists of the following components in parts by weight: 12 parts of copper ore tailings, 35 parts of composite Portland cement, 12 parts of fly ash ceramsite, and 5 parts of shale ceramsite 5.2 parts of zirconium coupling agent, 2.5-3.5 parts of water glass, 3.5-4.5 parts of sodium lauryl sulfate, 2 parts of waterproofing agent, 5.8 parts of sawdust waste, 2.8 parts of nucleating agent, SY-G type high performance 1.4 parts of swelling anti-cracking agent, 95 parts of water;

[0010] According to the above parts by weight, the preparation method of the aerated brick is as follows: first feed copper ore tailings, composite Portland cement, sawdust waste, and water glass into a pre-heating machine with a steam pressure of 1.3Mpa and preheated to 115°C. Foaming, after 1.8h pre-foaming to obtain pre-foaming material; then fully stir the pre-foaming material with fly ash ceramsite, shale cerams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com