An intelligent and efficient batching method for producing molybdenum-iron alloy with low cost and high yield

A molybdenum-iron alloy, high-yield technology, applied in the field of intelligent high-efficiency ingredients, can solve the problems of large limitations in raw material selection, long time-consuming, and small range of raw and auxiliary materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

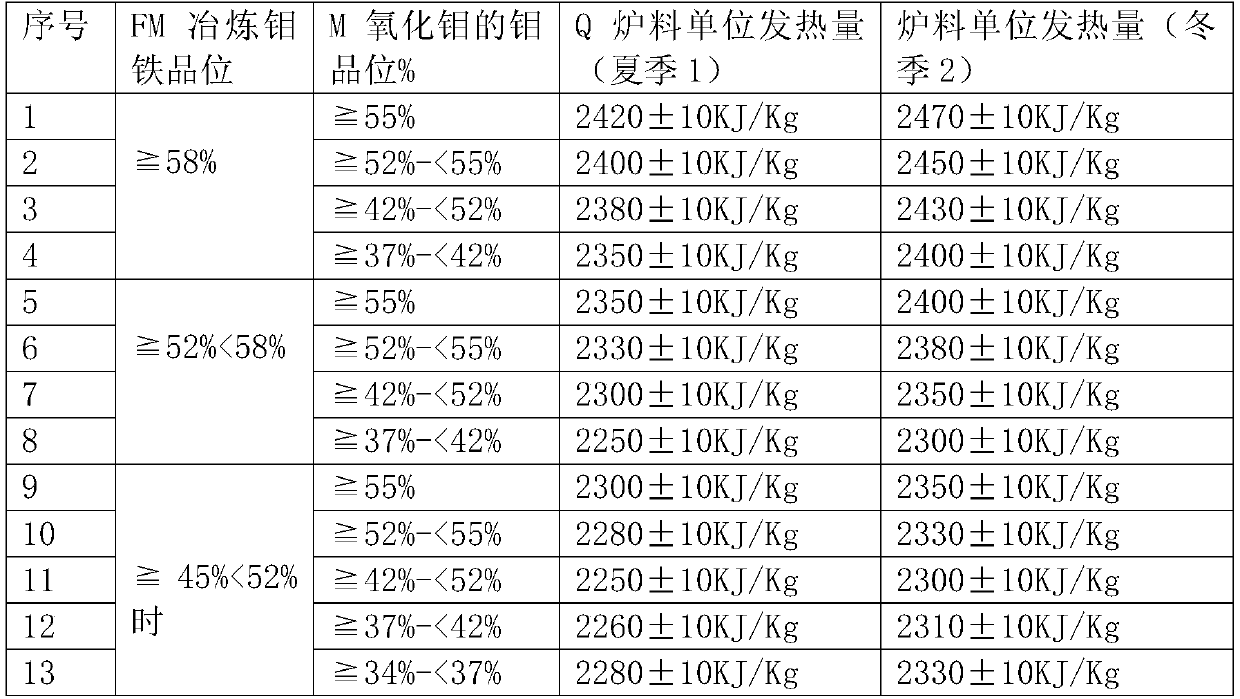

[0085] Adopt above-mentioned embodiment scheme to carry out batching, comprise the following steps:

[0086] Step 1: Enter the molybdenum iron grade FeMo60-A, enter the batch of molybdenum oxide as 24, enter winter 2 for the season

[0087] Step 2: Start the program

[0088] Step 3: Pop the Recipe

[0089]

[0090]

[0091] The calculation process of the above data is as follows:

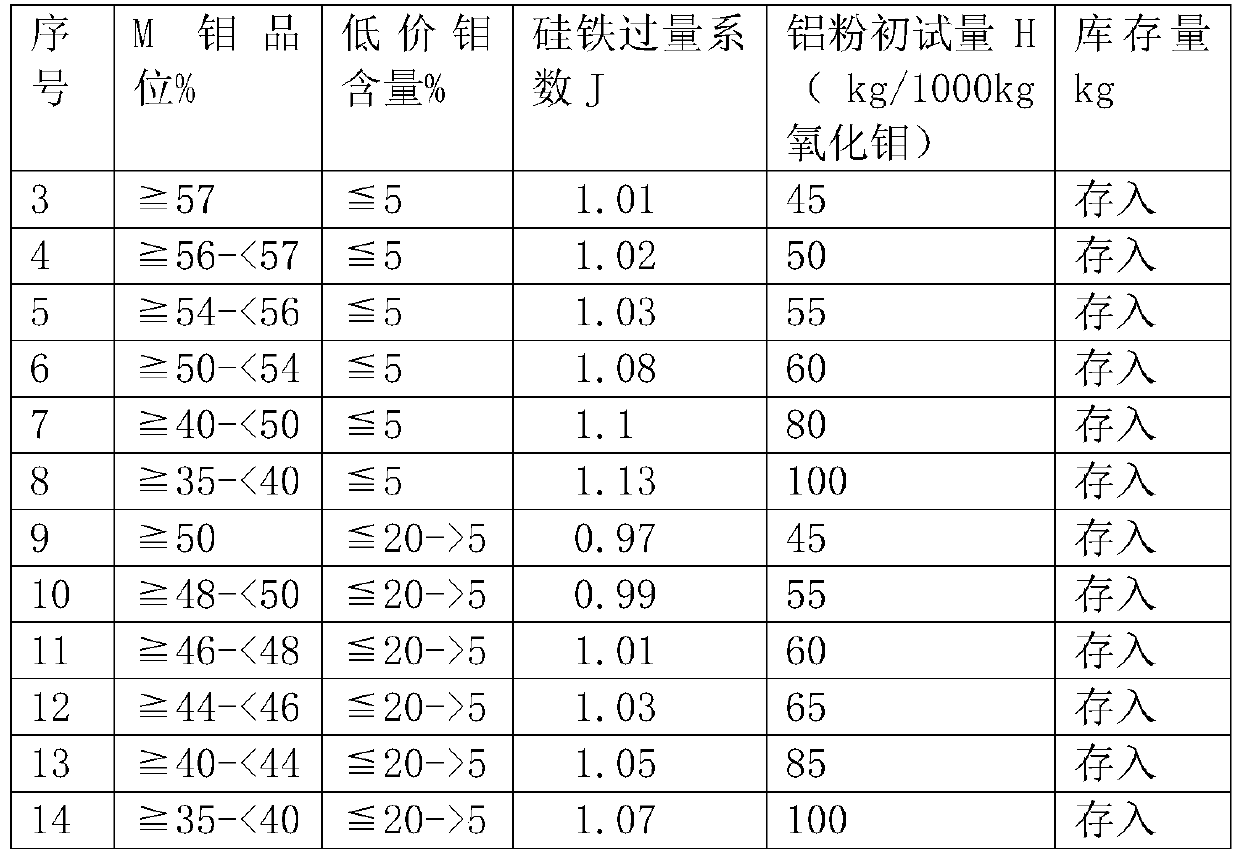

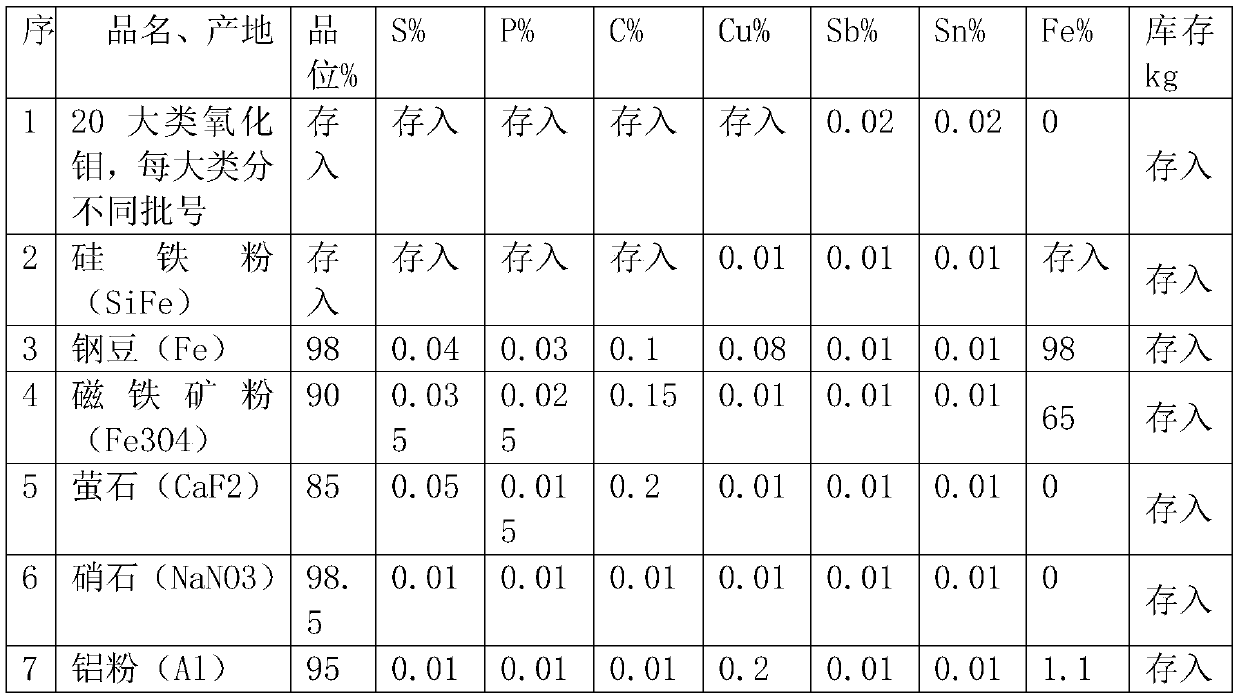

[0092]JS001: In the data of category C, the program selects category 9 molybdenum oxide with a grade of 60.55%, and the impurities are as shown in the above table

[0093] JS002: In the data of category C, the program selects ferrosilicon, containing 66.24% silicon and 16.43% iron, and the impurities are as shown in the above table

[0094] JS003: The program determines N=8 in the data of type B and type E, selects the initial test amount of aluminum powder H=45×0.8=36 (kg), and the amount of saltpeter is I=(45+10)×0.8=44( kg), the selected ferrosilicon excess coefficient is 0.97.

[0095...

Embodiment 2

[0112] Adopt above-mentioned embodiment scheme to carry out batching, comprise the following steps:

[0113] Step 1: Enter the molybdenum iron grade FeMo55-B, enter the batch size of molybdenum oxide as 24, enter summer 1 for the season

[0114] Step 2: Start the program

[0115] Step 3: Pop the Recipe

[0116]

[0117] Step 4: Smelting Results

[0118]

[0119]

[0120] The molybdenum-iron alloy in this embodiment has a molybdenum content of 58.02%, meeting the standard requirement of 55-60%; the molybdenum yield is 99.21%; impurities are completely qualified; completely qualified.

Embodiment 3

[0122] Adopt above-mentioned embodiment scheme to carry out batching, comprise the following steps:

[0123] Step 1: Enter the molybdenum iron grade FeMo50, enter the batch of molybdenum oxide as 30, enter the season as summer 1

[0124] Step 2: Start the program

[0125] Step 3: Pop the Recipe

[0126]

[0127] Step 4: Smelting Results

[0128]

[0129]

[0130] The molybdenum iron alloy molybdenum content of this embodiment is 53.17%, meets the standard 50-55% requirement; Molybdenum yield is 99.06%; Impurities are completely qualified;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com