Ultrahigh-specific-gravity polyamide material as well as preparation method and application thereof

A technology of polyamide and polyamide resin, applied in the field of modification of polymer composite materials, can solve the problems of low strength, complex process, product application restrictions, etc., and achieve excellent processing performance, simplify processing technology, and improve balance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

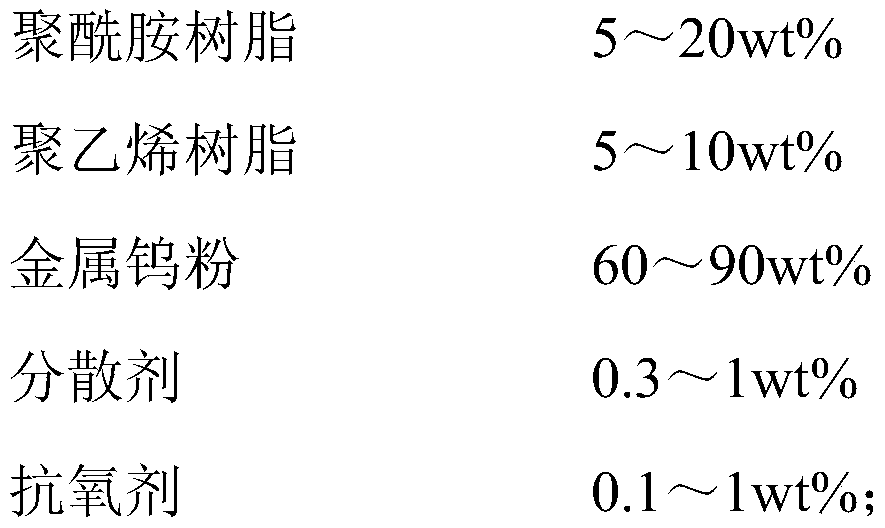

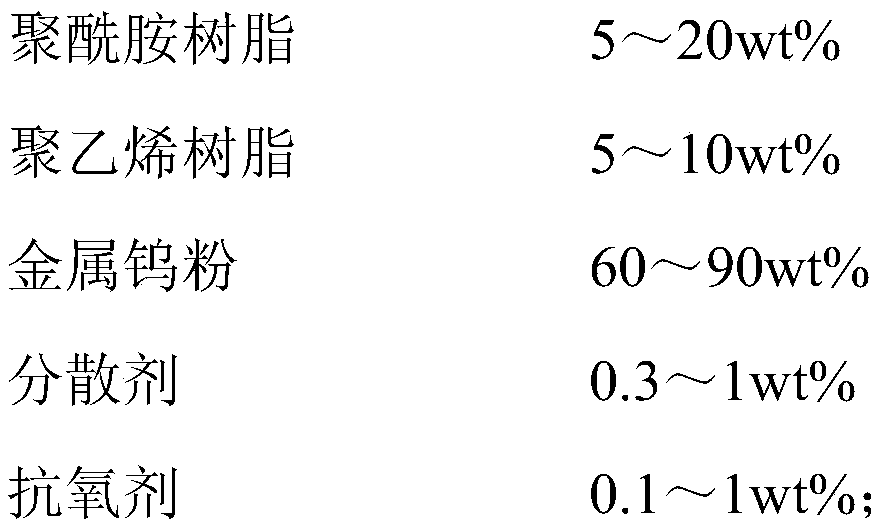

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of ultra-high specific gravity polyamide material, concrete steps are as follows:

[0036] (1) Weigh raw materials according to the formula, polyamide resin PA6 (Xinhui Meida PA6M2000) 10wt%, high-density polyethylene (Sinopec HDPE2200J) 5wt%, fluoropolymer processing aid PPA (3M, FX5920) 0.5wt% , antioxidant (Ciba, 1098 / 168) 0.6wt%, metal tungsten powder 83.9wt%. Then polyamide resin PA6 (Xinhui Meida PA6M2000), high-density polyethylene (Sinopec HDPE2200J), fluoropolymer processing aid PPA (3M, FX5920), antioxidant (Ciba, 1098 / 168) were added to Stir in a high-speed mixer for 5 to 10 minutes, and the speed of the host is 300 rpm.

[0037] (2) Put the uniformly stirred materials into a single-screw extruder for preprocessing, control the temperature of each heating section of the extruder at 220±10°C, and the screw speed of the main engine at 250±10r / min.

[0038] (3) After the material is extruded by a single screw, it is directly metered into...

Embodiment 2

[0041] The preparation method of ultra-high specific gravity polyamide material, concrete steps are as follows:

[0042] (1) Weigh raw materials according to the formula, polyamide resin PA6 (Xinhui Meida PA6M2000) 10wt%, high-density polyethylene (Sinopec HDPE2200J) 10wt%, fluoropolymer processing aid PPA (3M, FX5920) 0.5wt% , antioxidant (Ciba, 1098 / 168) 0.6wt%, metal tungsten powder 78.9wt%. Then polyamide resin PA6 (Xinhui Meida PA6M2000), high-density polyethylene (Sinopec HDPE2200J), fluoropolymer processing aid PPA (3M, FX5920), antioxidant (Ciba, 1098 / 168) were added to the Stir in a high-speed mixer for 5 to 10 minutes, and the speed of the host is 300 rpm.

[0043] (2) Put the uniformly stirred materials into a single-screw extruder for preprocessing, control the temperature of each heating section of the extruder at 220±10°C, and the screw speed of the main engine at 250±10r / min.

[0044] (3) After the material is extruded by a single screw, it is directly metered...

Embodiment 3

[0047] The preparation method of ultra-high specific gravity polyamide material, concrete steps are as follows:

[0048](1) Weigh raw materials according to the formula, polyamide resin PA6 (Xinhui Meida PA6M2000) 10wt%, high-density polyethylene (Sinopec HDPE2200J) 6wt%, fluoropolymer processing aid PPA (3M, FX5920) 0.5wt% , antioxidant (Ciba, 1098 / 168) 0.6wt%, metal tungsten powder 82.9wt%. Then polyamide resin PA6 (Xinhui Meida PA6M2000), high-density polyethylene (Sinopec HDPE2200J), fluoropolymer processing aid PPA (3M, FX5920), antioxidant (Ciba, 1098 / 168) were added to the Stir in a high-speed mixer for 5 to 10 minutes, and the speed of the host is 300 rpm.

[0049] (2) Put the uniformly stirred materials into a single-screw extruder for preprocessing, control the temperature of each heating section of the extruder at 220±10°C, and the screw speed of the main engine at 250±10r / min.

[0050] (3) After the material is extruded by a single screw, it is directly metered i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com