A low-surface, high-penetration, rust-bearing primer

A rusty primer and high-penetration technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as difficult construction, difficult grinding, and large rust removal project, so as to simplify the construction process and reduce Surface treatment process, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

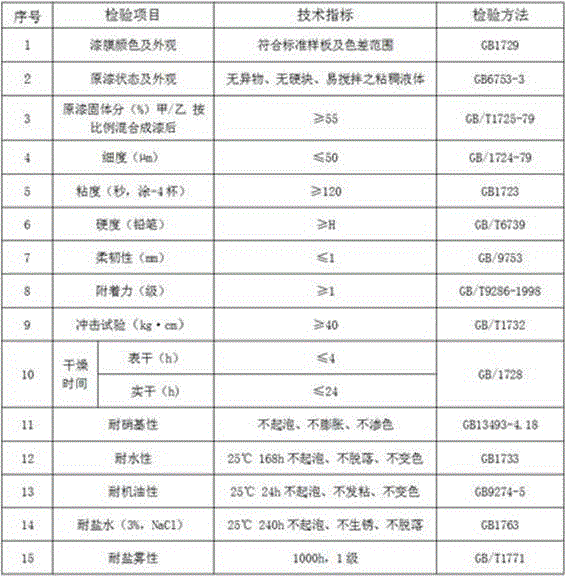

Image

Examples

Embodiment 1

[0034] A low-surface high-penetration rust primer, which consists of two parts: paint and curing agent:

[0035] (1) The raw material formula of the paint part is: modified epoxy resin 25 kg, fluororesin 15 kg, titanium dioxide 4 kg, barium sulfate 5 kg, iron oxide red 8 kg, ethylene glycol monobutyl ether 1 kg, dispersant 0.5 kg, 0.5 kg of defoamer, 5 kg of deionized water, 0.5 kg of rust conversion agent, and 0.01 kg of pH regulator;

[0036] (2) The raw material formula of the curing agent part is: modified fatty amine curing agent 99.5 kg, dispersant 0.5 kg.

[0037] The preparation method of described rusty primer comprises the steps:

[0038] Step 1: Preparation of paint

[0039] First put the modified epoxy resin and deionized water with 60% raw material into the seasoning kettle and stir evenly; then add dispersant, defoamer, ethylene glycol monobutyl ether, titanium dioxide, barium sulfate, oxidation iron red, and stirred at 800 rpm for 45 minutes; after stirring e...

Embodiment 2

[0045] A low-surface high-penetration rust primer, which consists of two parts: paint and curing agent:

[0046] (1) The raw material formula of the paint part is: 30 kg of modified epoxy resin, 10 kg of modified vinyl resin, 20 kg of amino resin, 3 kg of carbon black, 10 kg of barium sulfate, 5 kg of talcum powder, and 10 kg of zinc oxide , Ethylene glycol ether 2 kg, leveling agent 2 kg, modified bentonite 2 kg, deionized water 10 kg, rust conversion agent 3 kg, pH regulator 0.02 kg;

[0047](2) The raw material formula of the curing agent part is: modified polyamide curing agent 99 kg, substrate wetting agent 1 kg.

[0048] The preparation method of described rusty primer comprises the steps:

[0049] Step 1: Preparation of paint

[0050] First put the modified epoxy resin, modified vinyl resin and 60% deionized water into the seasoning kettle and stir evenly; then add leveling agent, modified bentonite, ethylene glycol ether, carbon black in turn while stirring , barium...

Embodiment 3

[0056] A low-surface high-penetration rust primer, which consists of two parts: paint and curing agent:

[0057] (1) The raw material formula of the paint part is: 35 kg of modified acrylic resin, 20 kg of vinyl resin, 5 kg of amino resin, 10 kg of medium chrome yellow, 10 kg of talcum powder, 10 kg of mica iron oxide, 5 kg of aluminum tripolyphosphate , Ethylene glycol monobutyl ether 3 kg, modified bentonite 0.5 kg, deionized water 12 kg, rust inhibitor 5 kg, pH regulator 0.03 kg;

[0058] (2) The raw material formula of the curing agent part is: 70kg of modified polyamide curing agent, 29.7 kg of modified m-xylylenediamine curing agent, and 0.3 kg of defoaming agent.

[0059] The preparation method of described rusty primer comprises the steps:

[0060] Step 1: Preparation of paint

[0061] First put the modified acrylic resin and 60% deionized water into the seasoning kettle and stir evenly; then add modified bentonite, ethylene glycol monobutyl ether, medium chrome yell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com