A low-cost method for preparing large-size single-crystal graphene

A single crystal graphene, large-scale technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of single crystal substrate surface treatment process complex, expensive, difficult to reuse, etc., to achieve good Application prospects, simple method, and the effect of omitting the surface treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

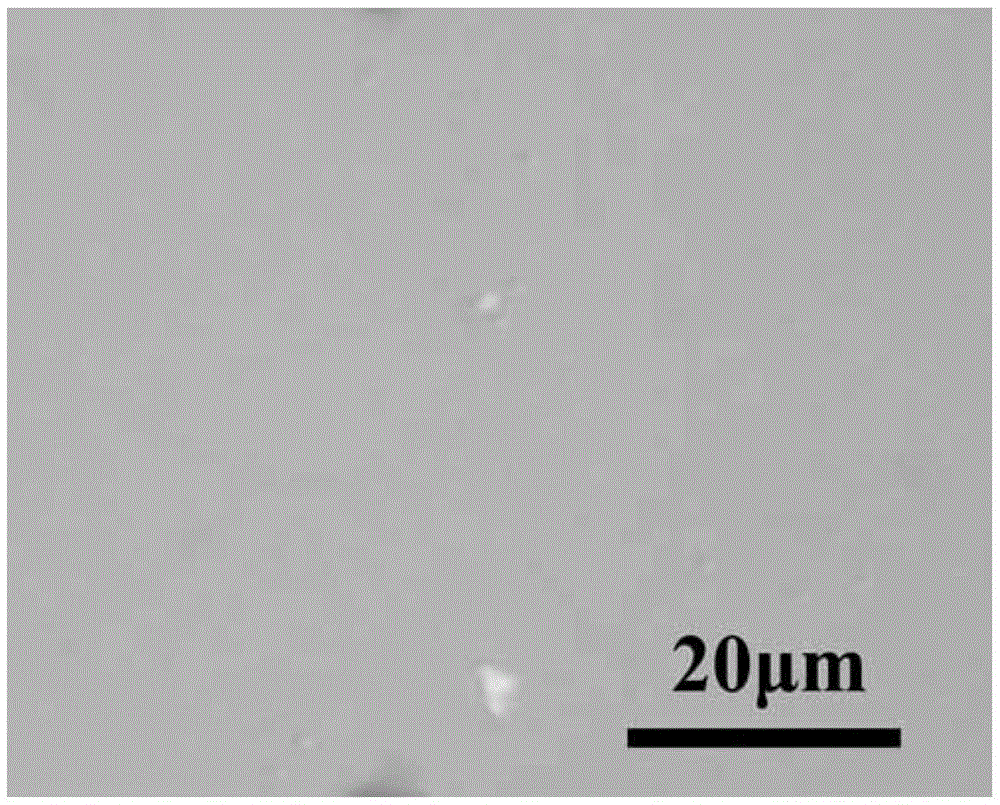

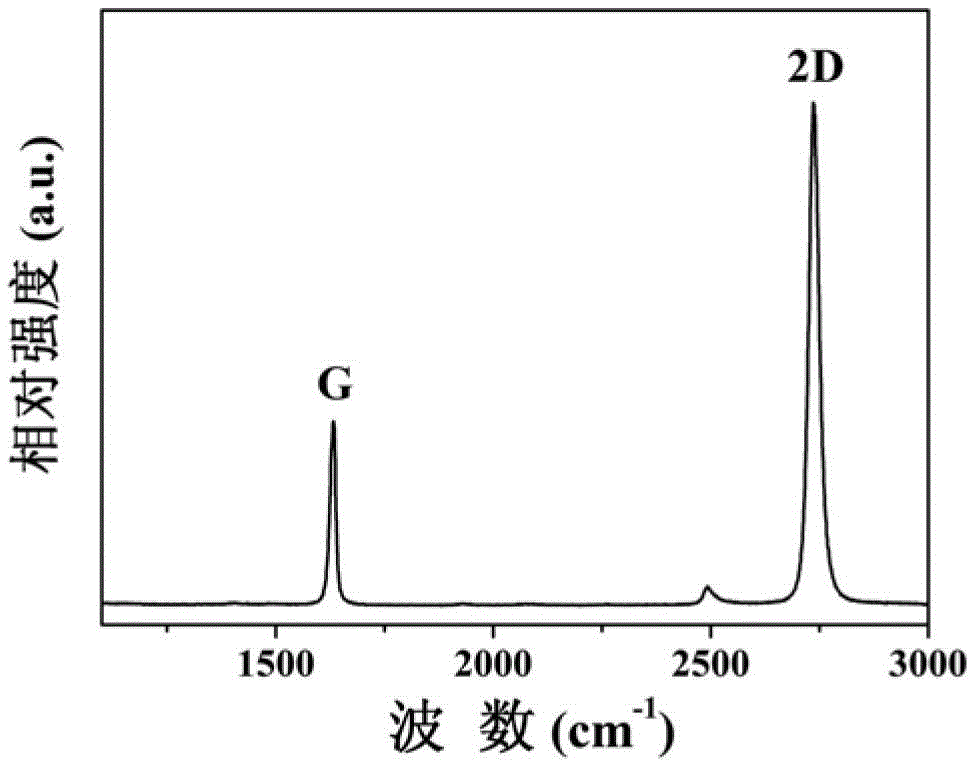

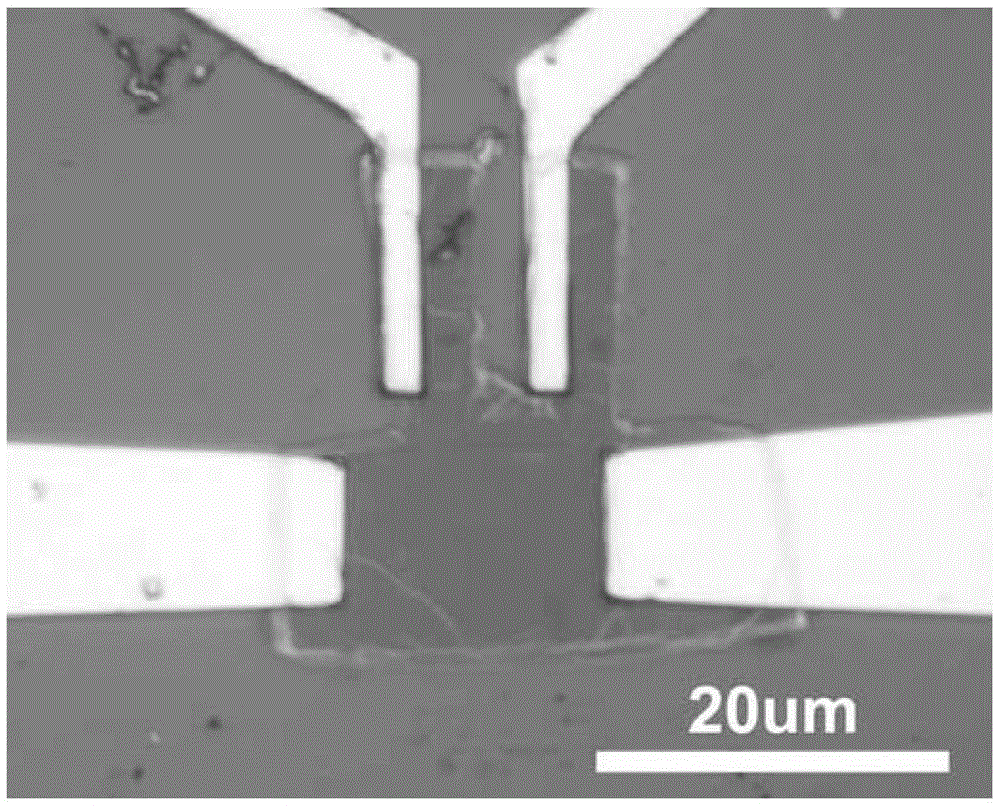

[0020] Specific embodiment one: a kind of low-cost preparation method of large-size single-crystal graphene of the present embodiment is to carry out according to the following steps:

[0021] 1. Using the electron beam evaporation method, using metal as the evaporation source, in a high vacuum environment, it is 1×10 -3 ~1×10 -4 Under Pa, a single crystal metal film is evaporated on a single crystal mica substrate; wherein, the evaporation rate is 0.02-0.20nm / s, the substrate temperature is 450-650°C, and the thickness of the evaporated single-crystal metal film is 500-1000nm;

[0022] 2. Put the single crystal metal thin film obtained in step 1 into the chemical vapor deposition equipment, evacuate to 3Pa, and inject H 2 , Ar, H 2 The flow rate is 50sccm, the Ar flow rate is 100sccm, and the working pressure is 1×10 5 Pa, then heat up to a heat treatment temperature of 850-1000°C, and a heat treatment time of 30-120min;

[0023] 3. After heat treatment, raise the tempera...

specific Embodiment approach 2

[0029] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the metal evaporation source in step 1 is copper, nickel or cobalt. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the evaporation rate in step 1 is 0.02 nm / s. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com