Powdered metallurgical piston ring and process for production thereof

A powder metallurgy and piston ring technology, applied in the field of piston rings, can solve the problems of high quality requirements of piston rings, large production investment, and difficult processing, and achieve the effects of reducing surface treatment procedures, reducing production costs, and shortening production cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

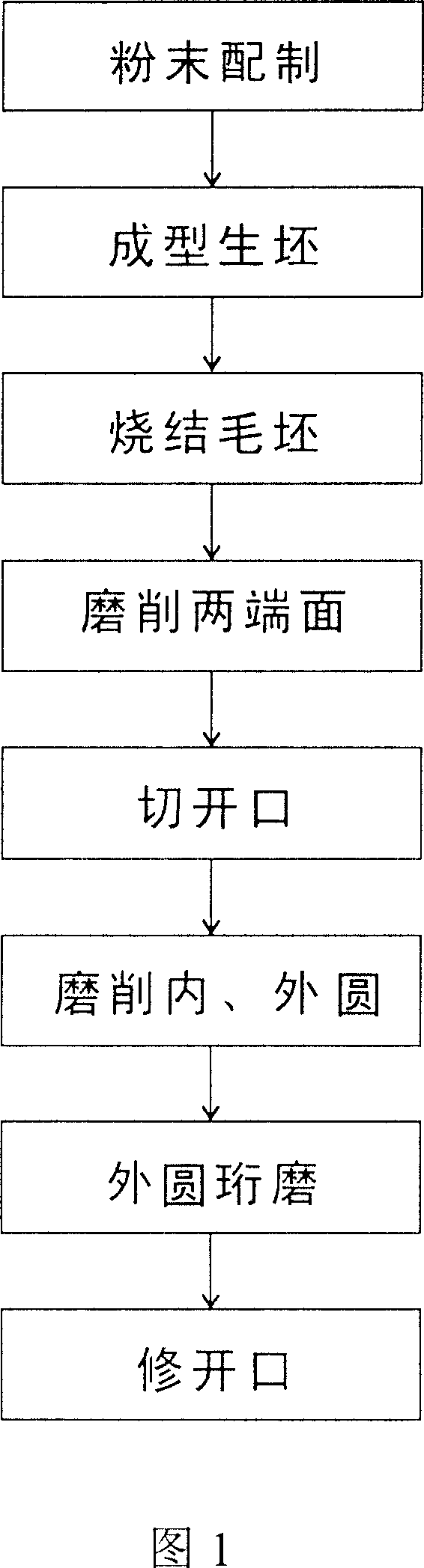

[0016] Powder preparation: 70wt% of the hard phase iron-containing boride (wherein, 15wt% of boron carbide, 4wt% of potassium fluoroborate, 81wt% of iron powder), 0.02wt% of RECe-40 mixed rare earth elements, and the rest are Steel powder, mixed ingredients, after conventional wet grinding, filtration, drying process, prepared into the required powder, and then mixed with a small amount of paraffin, ready to use;

[0017] Forming the green body: Using a press and a mold, press the above-mentioned prepared powder to form the required green body;

[0018] Sintered blank: put the green compact in a sintering furnace and sinter at 1100°C for 40 minutes to obtain the required piston ring blank;

[0019] Grinding both ends of the blank: Grinding the two ends of the blank to the required size with a counter grinder;

[0020] Cutting: use a wire cutting machine to cut the opening;

[0021] Grinding inner and outer circles: Grinding the inner circle with an internal grinder to meet t...

Embodiment 2

[0026] The production process is the same as in Example 1, except that 80wt% of the hard phase iron-containing boride (wherein, 20wt% of boron carbide, 5wt% of potassium fluoroborate, and 75wt% of iron powder) is used in the powder preparation process, 0.03wt% RECe-48 mixed rare earth elements, and the rest is iron powder. In addition, in the process of sintering the blank, the sintering temperature is 1300° C. and the sintering time is 20 minutes.

[0027] The powder metallurgy piston ring made by this method can be used in gasoline engines of heavy vehicles.

Embodiment 3

[0029] The production process is the same as in Example 1, except that 30wt% of the hard phase iron-containing boride (wherein, 25wt% of boron carbide, 3wt% of potassium fluoroborate, and 72wt% of iron powder) is used in the powder preparation process, 1wt% of RECe-40 is mixed rare earth elements, and the rest is iron powder. In addition, in the process of sintering the blank, the sintering temperature is 1250° C. and the sintering time is 30 minutes.

[0030] The powder metallurgy piston ring made by this method can be used in diesel engine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com