Optical recording medium, recording method thereof and evaluation method of optical recording medium

A technology of optical recording medium and recording method, applied in the direction of optical recording/reproduction/erasing method, optical recording head, optical recording system, etc., capable of solving problems such as recording difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0179] Since there is no DVD medium corresponding to high-speed recording of 20 m / s or higher on the market, a sample disk was made.

[0180] will be composed of ZnS and SiO 2 The 60nm thick lower protective layer made of the mixture of GaSbSnGe alloy, the 15nm thick recording layer made of ZnS and SiO 2 A 10-nm-thick upper protective layer made of a mixture of Ag and a 200-nm-thick reflective layer made of Ag are sequentially laminated on a 0.6 mm-thick and 120-mm-diameter polycarbonate DVD+RW substrate with a sputtering process. A spiral continuous group with a track pitch of 0.74 μm. Also, another substrate was adhered on the reflective layer by a commercially available UV resin adhesive for disks to make it a 1.2 mm thick disk. Its shape fully meets the DVD+RW specification.

[0181] Subsequently, the recording layer is crystallized over the entire surface by an initiation device for a phase-change type disk. Produced disc is good and meets various specifications of DV...

Embodiment 2

[0203] For the same sample tray as in Example 1, the recording was performed by using the same method as in Example 1, except that the parameters in Table 3 were used instead of Table 1.

[0204] table 3

[0205] speed

Scanning speed v(m / s)

Clock cycle T(ns)

T LP3 / T

T CP3 / T

3.3×

11.52

11.6

0.313

2.125

4.0×

13.96

9.6

0.328

1.850

5.0×

17.45

7.6

0.344

1.575

6.0×

20.94

6.4

0.359

1.300

6.0×

20.94

6.4

0.625

1.300

7.0×

24.43

5.5

0.656

1.025

8.0×

27.92

4.8

0.688

0.750

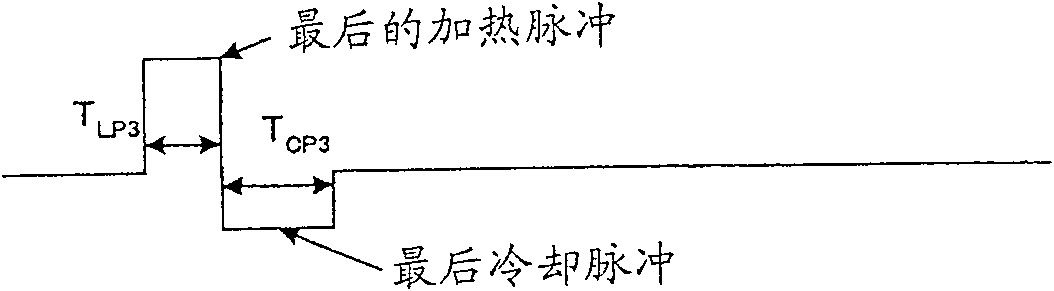

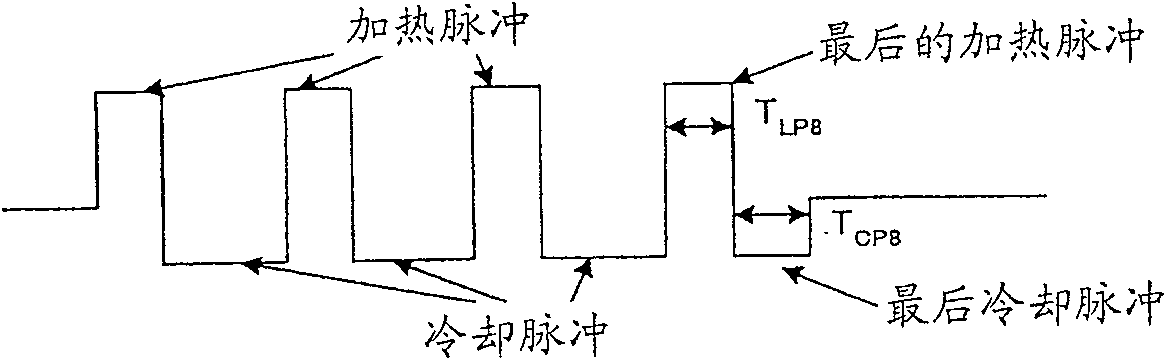

[0206] Parameter T LP3 and T CP3 The correlation with scan speed is shown in Figure 12 . T CP3 Use a continuous function to determine, but T LP3 Use two functions to determine. That is, at v0 within the range of T LP3 / T=g 1,3 (v)=0.00489v+0.258; when ...

Embodiment 3

[0210] For the same sample disc as in Example 1, the recording was performed in the same manner as in Example 1, except that a pattern with alternating 10T marks and 10T gaps was recorded by a 2T strategy with n=10 and m=5 and using the table In addition to the parameters in 4. Here, the length of the heating pulse was made the same as that of the last heating pulse, and the same value as in Example 1 was set.

[0211] Table 4

[0212] speed

Scanning speed v(m / s)

Clock cycle T(ns)

T LP3 / T

T CP3 / T

3.3×

11.52

11.6

0.313

1.875

4.0×

13.96

9.6

0.375

1.750

5.0×

17.45

7.6

0.438

1.625

6.0×

20.94

6.4

0.500

1.500

6.0×

20.94

6.4

0.500

0.500

7.0×

24.43

5.5

0.563

0.250

8.0×

27.92

4.8

0.625

0.000

[0213] Parameter T LP10 and T C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com