Quantitative transportation device for high viscosity materials

A conveying device and high-viscosity technology, applied in the direction of liquid ingredient supply device, etc., can solve the problems of easy wear of the driving wheel, low volumetric efficiency, large flow pulsation, etc., and achieve the effect of improving efficiency, high volumetric efficiency and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

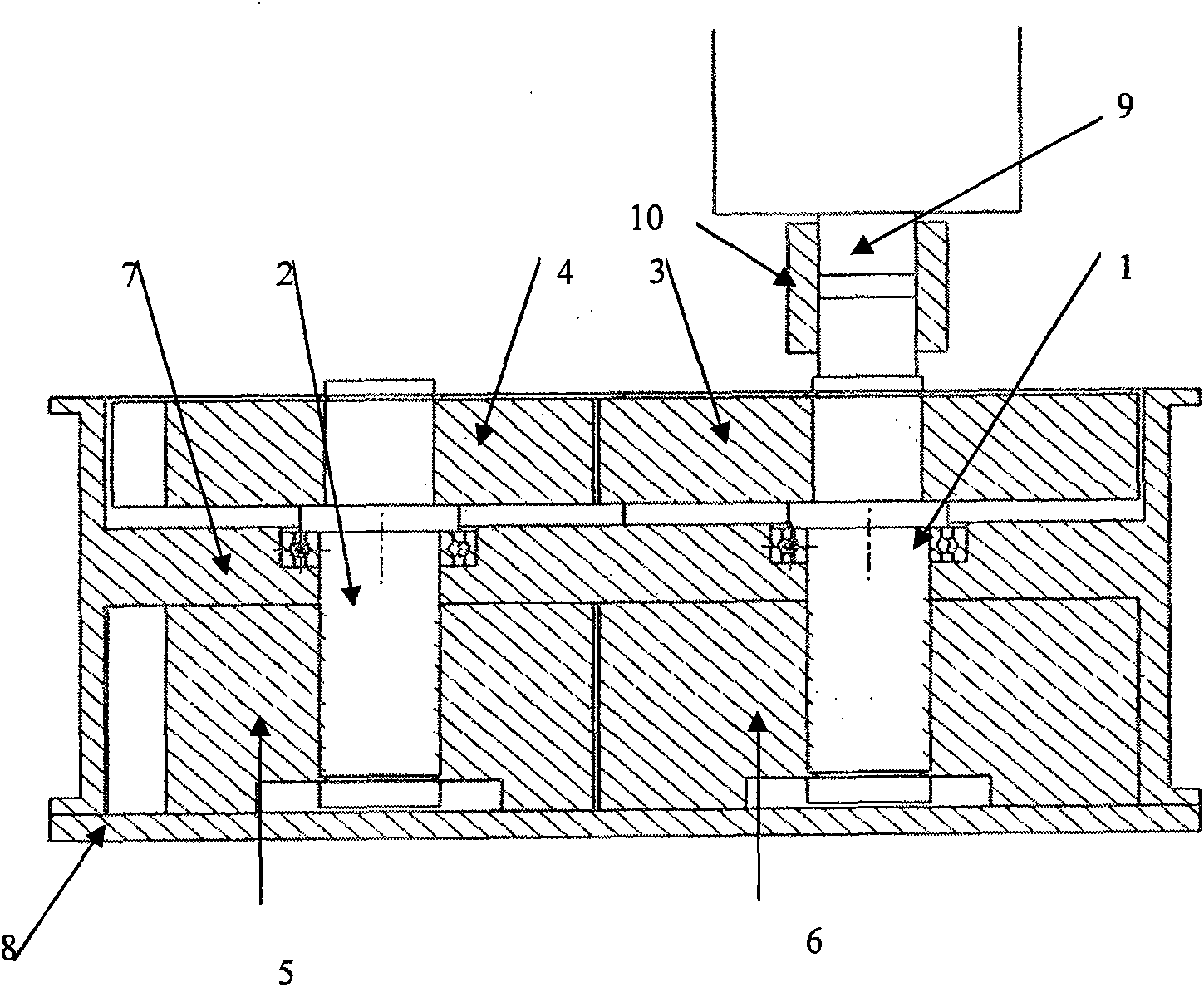

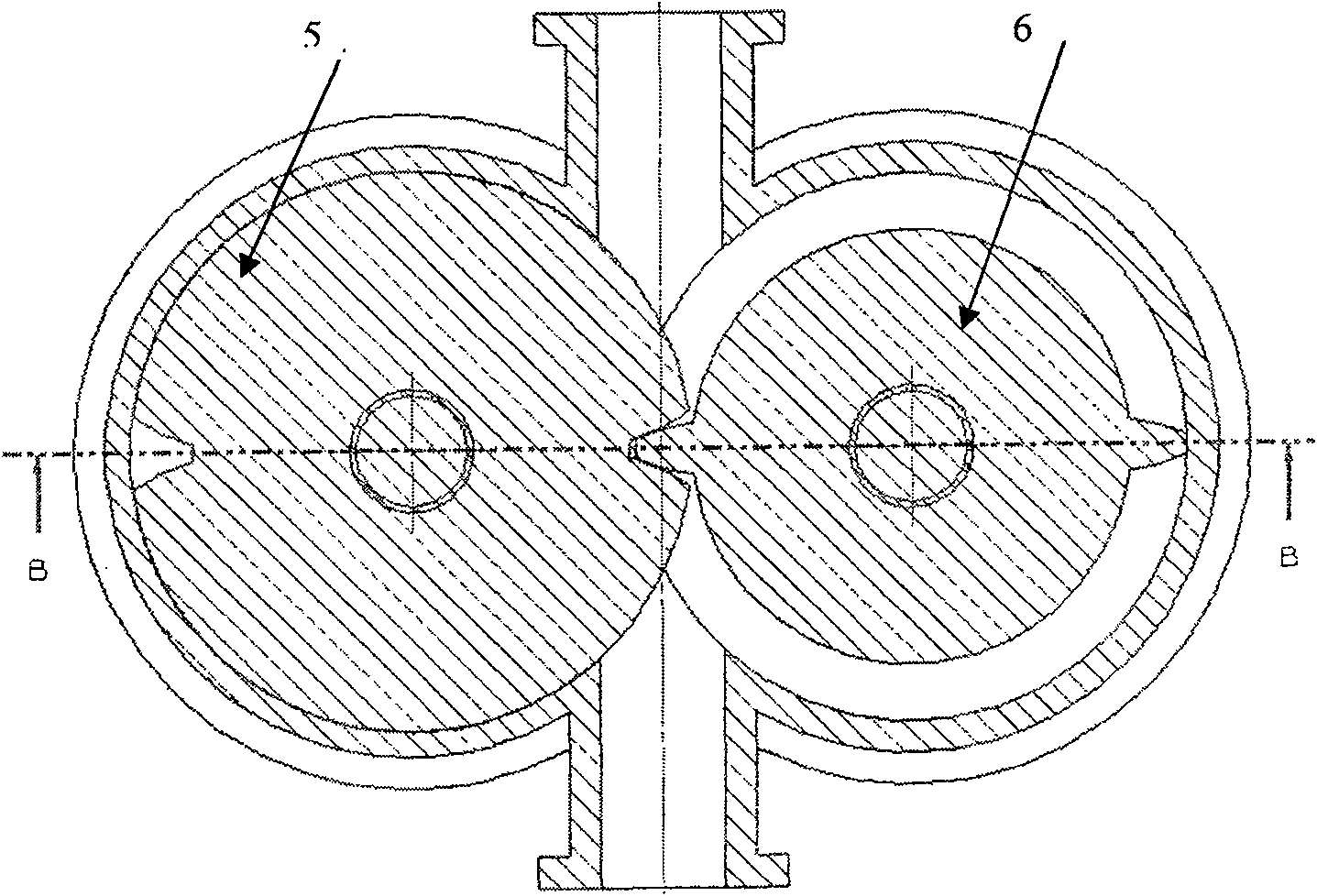

[0009] combine figure 1 , the quantitative conveying device for high viscous materials of the present invention, the sealing wheel 5 is installed on the auxiliary transmission shaft 2, the conveying wheel 6 is installed on the main power shaft 1, the sealing wheel 5 and the conveying wheel 6 are in the conveying cavity of the pump body 7, and are connected by The pump cover 8 is sealed, the sealing wheel 5 and the conveying wheel 6 are meshed with each other; the main transmission gear 3 is installed on the main power shaft 1, and the driven gear 4 is installed on the auxiliary transmission shaft 2. The main transmission gear 3 and the driven gear 4 Intermeshing with each other; the main shaft of the motor 9 is directly connected with the main power shaft 1 through the coupling 10. Among them, the conveying wheel 6 has a rotor with two scraping teeth, and the two scraping teeth are symmetrically distributed at an angle of 180 degrees on the circumference. When working, the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com