Bit shank structure of gadding machine

A technology for rock drills and shank tails, which is applied in the field of improvement of shank shank structures. It can solve the problems of affecting the service life of shank tails and low fatigue resistance, and achieve the effects of improving energy utilization, reducing energy loss, and accelerating rock drilling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

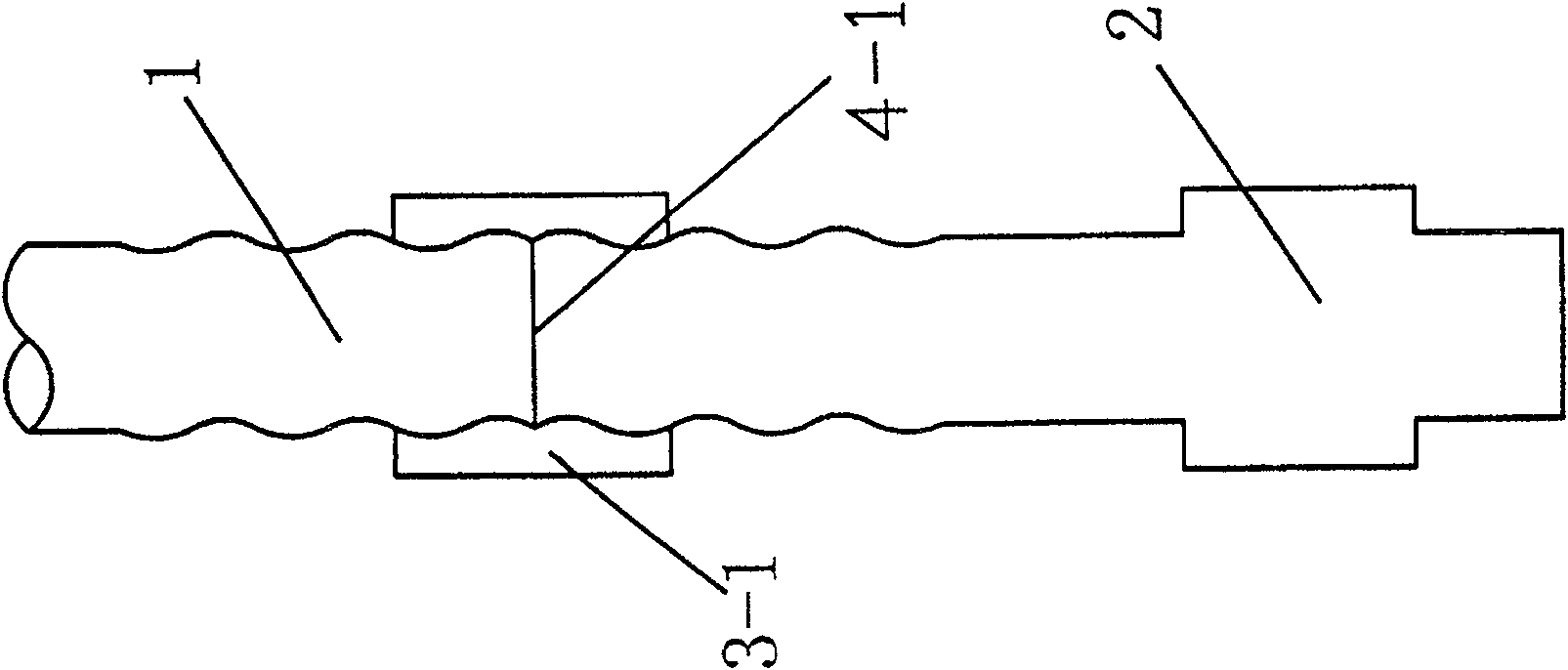

[0029] In Fig. 1, 1 is a drill rod, 2 is a drill tail, 3-1 is a casing, and 4-1 is a bearing surface. Structural features of the present invention are as follows:

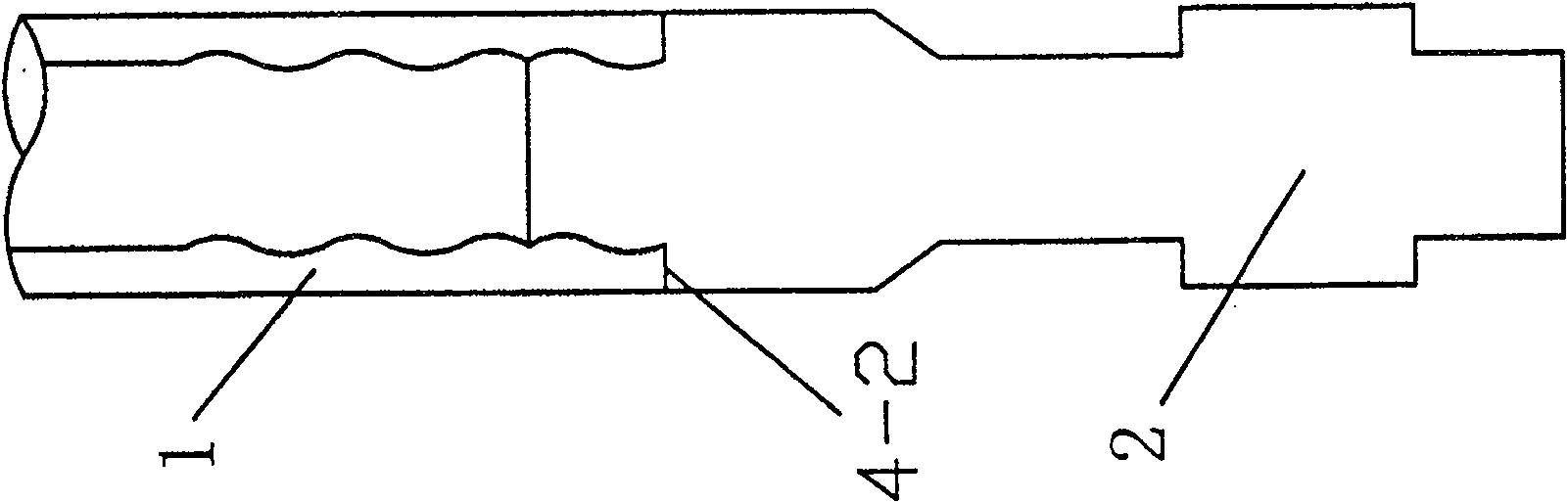

[0030] 1. Do not change the internal structure of the rock drill, retain the type of screw shank tail, and use the empty slit end face at the root of the male thread as the position for transmitting the stress wave bearing surface, such as image 3, Figure 4 Show.

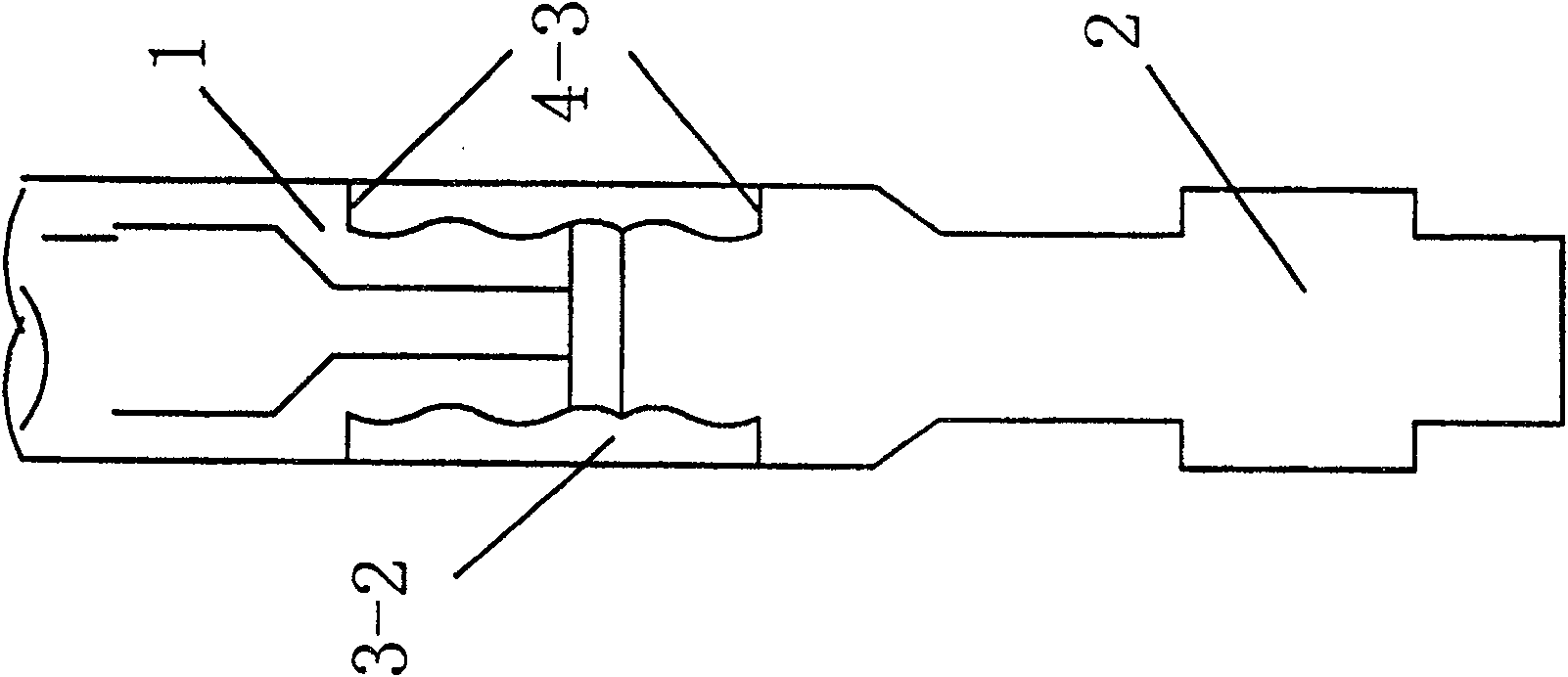

[0031] 2. The screw type shank 2 and the rock drilling tubular drill rod 1 are connected through the double bridge nut bushing 3-2, and the bearing surface for transmitting the rock drilling stress wave is designed on the two end faces 4 of the double bridge nut bushing -3, as in Figure 3 shown. 3-2 is the double bridge nut bushing among Fig. 3. When the thread diameter or thread type of the rock drilling tubular drill rod and the screw shank are different, the half-bridge nut sleeve connection will be used between the two, such as Figure 4 sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com